Meadowbank TAFE Multi-Trades Hub

YTB Consulting

Johnathon Walker

George Cory Darroch

YTB Consulting

Johnathon Walker

George Cory Darroch

A GD & JW Draft Submission

1.0 GD & JW Issued for Construction

This CPMP has been prepared for the nominated Head Contractor of the Meadowbank TAFE MultiTrades Hub, Hansen Yuncken Pty. Ltd. The details of the Project Sponsor and Head Contractor are as follows:

CPMP Key Contacts

Role Name

Project Sponsor/Principal

Details

NSW Government/TAFE NSW Contact details are as per TAFE NSW’s direction

Head Contractor Hansen Yuncken Pty. Ltd. This report has been prepared for construction in line with the Head Contractor’s direction.

Aligned with the direction of our client, the CPMP has been developed to guide all construction activities, from the tendering phase through to commissioning, handover, and project close. These activities are directed by several sub-plans, diagrams, figures, and external documents, all of which have been detailed within.

The CPMP has become the intellectual property of Hansen Yuncken, and as such any changes beyond this revision are the sole responsibility of Hansen Yuncken. YTB Consulting accept no liability beyond this current report version.

A Project Charter has been developed as an externally facing overview of the Meadowbank TAFE project, intended as the key point of communication between the Project Sponsor and Head Contractor during the initiation phase of the project. The Project Sponsor is an intended recipient of the Project Charter.

This document outlines the methodologies and assumptions adopted in the creation of the subsequent detailed management plans, while serving as a general overview for how the project will be carried out. Where any information withing the Project Charter conflicts with a detailed management plan, the management plan is to be adopted as the greater authority.

Following the NSW Government’s investment in the Meadowbank Education & Employment Precinct, and the relocation of two schools to the large Meadowbank TAFE campus site, a case for change has been presented to update and improve existing TAFE infrastructure. This is in line with high growth forecasts for skills-based qualifications, and the demand for TAFE to become further aligned with technology and industry.

Strong growth in jobs forecast in both the Infrastructure, Energy and Construction and the Digital Technologies sectors, is driving high demand for associated courses. With the constraints of the current TAFE NSW Meadowbank site, the only way to meet this increased demand is to invest in new infrastructure.

The design objectives for the new TAFE building are to create a learning environment that is a better fit – contextual, and a deeply related part of its surroundings to stand for generations to come as a valuable part of the community. Better performance is also crucial, part of TAFE’s identity as agile and future oriented. Efficiency and adaptability come from sustainable, future-proofed design, and fit for purpose spaces will be a teaching exemplar to the trades industry. An extensive ECI process culminated in detailed schematic design drawings, with workshops and design collaboration to deliver innovation in material selection, low maintenance outcomes and a high level of end user satisfaction.

Following the above, TAFE NSW has proposed to undertake the following works:

• A new Multi-Trades and Digital Technology Hub, featuring:

• A new separate Multi-Storey Carpark

• General TAFE Meadowbank Precinct Works

Meeting the above criteria will mean the Head Contractor has delivered high quality, future focused, innovative, state-of-the-art educational facilities that meet the current and future TAFE and community needs and comply with the client’s design requirements. Achieving the above criteria, as well as the client’s expectation of a major capital works project delivered on time and on-budget, will lead to a successful project outcome for all stakeholders.

The objectives of the Meadowbank TAFE Multi-Trades & Digital Technology Hub are as follows:

• Provide increased opportunities for industry partnerships and collaboration

• Address the changing nature of the workforce by offering practical training experiences

• Improve student experience and amenity

• A valuable contribution to the social and cultural development of Meadowbank and Trades training for the future

The following table presents the major deliverables that the project’s product, service or result must meet in order for the project objectives to be satisfied

Project Major Deliverables

Major Deliverable Description

Multi-Trades & Digital Technology Hub

Multi-Storey Carpark

A new activated TAFE Hub building to enhance learning opportunities with a focus on digital technology

Carparking to facilitate added students and staff travelling to the area.

Precinct Works Deliver upgrades to the entire TAFE precinct, to align with the precinct master plan and better support growth in the area.

The estimated cost for the Meadowbank TAFE development is $110m. This is to be funded in full by the NSW Government. Detailed budget breakdown and cost plan is within Section 7.

Assumptions

• All information drawn from official sources (TAFE NSW, NSW Govt.) was understood to be true and correct

• The scope of works as defined in the Scope Management Plan represents the entirety of the works required

• The project team and Head Contractor have the skills required to deliver the project

• Site investigations have confirmed the details of latent conditions to the satisfaction of the Principal and Head Contractor, such that these risks are adequately detailed in the Head Contract

• Market conditions have been assumed as favorable. Generally, risks beyond Covid-19 have not been included in this report – e.g., timber shortages, steel supply issues.

• All ground conditions have been identified by the Geotechnical report.

Constraints

- Scope:

Regarding scope, constraints are dictated simultaneously by both the client and existing TAFE protocols and campus restraints. Scope management will serve to reduce scope creep and keep corresponding project factors on track.

- Time:

Time constraints come from the TAFE and schools teaching periods. During construction, the project must adhere to the learning periods and their corresponding exam times to ensure that no disruption effects students and teachers at critical times

The end date for the project is also fixed for the same reason. The TAFE must be ready for reopening term 2 2022; this means that OC and completion must be achieved by approximately May 2022.

- Cost:

Due to the NSW Government funding model for the TAFE development, cost constraints come generally in the form of long lead times on approved changes to funding. With a private client, equity may be more accessible and allow more flexibility in the program. However, with Government, all changes must go through a lengthy review and approval process. This means any variances of cost changes can significantly impact programme.

Fig. 3: The existing traffic management constraints on the project

Covid-19 (Force Majeure)

Interface with live TAFE environment

Interface with surrounding neighbours

Complex stakeholder collaboration

Asbestos in soil

Existing Site Constraints

Stringent provisions in head contract to ensure Covid-19 risk is held by client.

Students and access must be carefully monitored. Live TAFE environment means vibration and dust must be minimised. Quiet times must be observed.

Very close proximity to surrounding residents raises risk. Engage with residents and use strict environmental control measures.

Multiple stakeholders mean centralised communication strategies are crucial to success.

Large amounts of asbestos present due to fill. ACM risk is borne by builder based on provisional sum in HC.

Due to the nature of the existing site, significant barriers to material movement and access through local roads exist, as per above figure. Consultation and scheduling deliveries during working hours will seek to mitigate this risk of negative stakeholder interactions.

Team Members

George is an experienced and effective Project Manager. Having completed multiple public projects throughout Australia, he brings a wealth of experience in all facets of a project. Strengths lie with stakeholder engagement and management.

Johno is a well-known and prestigious executive with a large multi-national developer. Preceding over multiple high-profile projects throughout Australia and Europe, Johno brings a wealth of experience in the residential and commercial sectors as a senior executive.

A key identified risk is communication breakdown due to busy schedules and time management. This will be mitigated by scheduling regular meetups to ensure they are adhered to.

A further issue is not being able to visit site or obtain information. Mitigation strategy here is that strict information sharing protocols have been decided on.

For the Meadowbank TAFE project, project scope is defined by several critical documents, policies and requirements. These are an assembly of government requirements, client directives, user requirements and contract conditions, and are made up as follows:

• The GC21 is the latest version of the standard construction contract created by the NSW government and is used on government contracts over $2mil. On the Meadowbank TAFE project, the head contractor will be engaged under a GC21 contract, with some departures.

• The PPR sits adjacent to the GC21 Contract and all contract design documents and provides a detailed written and visualized scope for the intentions of the project. This will include detail surrounding project background and design intent (such as exemplar projects or references); a detailed description of the works, and then a breakdown of the delivery process – from design requirements; to coordination flowcharts, TRG processes, and client communication protocols.

• As with any construction project in Australia, there are several generic compliance requirements the project must adhere too. These include the NCC, BCA (Building Code of Australia) and Australian Standards.

• Further to the above, specific requirements are placed on the project by authorities. Due to being valued over $100mil, the project must comply with State Significant Development requirements. This means preparing an SSDA (which overrides any requirement for a DA (Development Application)) and navigating approval processes. Local council requirements must still be adhered to

• Drawings and specifications are created by the architect and consultants and exist as the main definition of the contract scope. They detail the exact construction, design, and requirements for the finished product.

• VE is a component of the Meadowbank TAFE project and is an ongoing process of working with consultants and the client to minimize costs for the client, refining the product and changing scope where necessary.

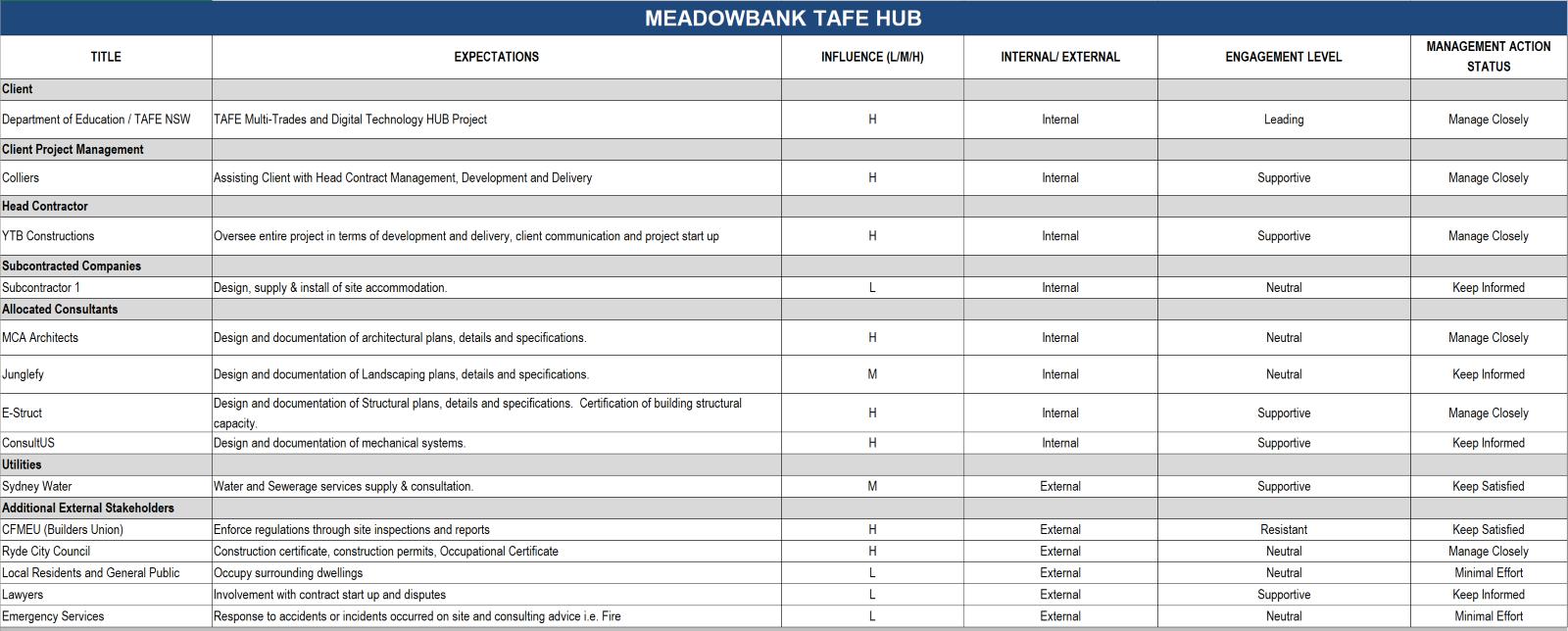

Stakeholder Requirements

• Stakeholder requirements are covered in the Head Contract, PPR and SSDA, where details such as community consultation and client reporting structures are detailed.

Deliverables & Business Case

The Meadowbank Education & Employment precinct overall plan includes the construction of a new Multi-Trades and Digital Technology Hub at Meadowbank TAFE, that meets a world class standard comparable to TAFE and vocational learning spaces around the world, creating a new precedent for TAFE in Australia. Specifically, the project will aim to go above and beyond statutory requirements, targeting a 4-Star Greenstar Certification.

This project involves the design completion and construction of a new Multi-Trades and Digital Technology Hub, a Multi-Storey Carpark and Precinct Works as detailed through contract documents, comprising the following:

• A new Multi-Trades and Digital Technology Hub

o Flexible and digitally enabled learning spaces

o Industry engagement spaces

o Staff workplaces

o Meeting rooms

o End of trip facilities

o staff/student amenities; and

o associated landscaping

• A new separate Multi-Storey Carpark

• General TAFE Meadowbank Precinct Works

o Demolition and existing Buildings D and E and make good

o Upgrades to the Southern Plaza

o Adjustments to the grade change between Building H and Building D and E to achieve pedestrian access after demolition of D and E; and

o Minor interface works at the boundary between the new Meadowbank School and the TAFE NSW Meadowbank entry at Rhodes Street.

The Principal’s requirements are to deliver the new TAFE on time and on budget to create a world-class learning center as part of Ryde’s status as an education center. Crucial to this is the ECI phase and value-engineering options provided by the builder during this phase. These include specific cost-saving areas, such as changing the carpark from underground to above ground and separate. This includes constructability analysis. Critical analysis of project management and continual reporting to the client is crucial to project delivery.

Finally, the project must be carried out on time to ensure opening of the new TAFE facilities and upgrades for operation in line with the target opening of the new Meadowbank School by Term 1, 2022.

To achieve handover requirements by the client, a number of factors must be met. In general, the product and deliverables must be delivered to contract requirements – on time and on budget, and to all required specifications. However, from a quality perspective, a number of more detailed provisions are in place to ensure a defect free handover. These are detailed further in Section 8 – Quality Management Plan, however a summary of the key points follows:

• Commissioning and handover activities have been documented and taken place to ensure TAFE staff and facilities managers are trained in using the new building. All necessary records and ongoing warranty and maintenance agreements have been supplied.

• As-built documents and all relevant handover material, and certificates have been provided, including ownership rights to the BIM where relevant.

• All regulatory and statutory requirements (e.g. Occupation certificate) have been fulfilled, and documentation has been supplied to the client.

• Defects, where applicable, have been identified and resolved, or acknowledged as component of the ongoing defects liability period.

Key Milestones

Refer Section 3 – Programme Constraints

Generally, the project is constrained by contractual conditions, contract documents and drawings, as well as time and budget. Specific to the project, however, are the constraints which come with working around a live environment.

The TAFE represents constraints in a number of ways. Crucially, the TAFE calendar must be adhered to –noisy works during class terms must be limited, and noisy works during exam periods must be totally

mitigated. Further to this, SSDA conditions impose restrictions on working times (7am-6pm) that must be adhered to, to alleviate impact on residents and reduce the risk of receiving a fine.

Further, the WHS standard set by the client (NSW Government) means extra constraints are placed on the project in terms of incident reporting and auditing. Resources must be provided by the Head Contractor to allow for these events. This is combined with a complex stakeholder structure of a clientside project manager, meaning clarity in reporting and communication guidelines must be established from the start of the project.

Portions of the public domain works have been absorbed by Roberts Co as part of the construction of the new schools at Meadowbank and are therefore excluded from contract documentation. This is along with all plaza works that include the railway station; rail lines are outside the scope of the project and therefore these works will be undertaken by a civil contractor.

To commence the TAFE precinct works, the existing TAFE buildings must be vacated by a certain date such that demolition can commence. If this does not happen, the program of works will be pushed back. Further, decanting of items into the new building can only commence once the spaces are ready; meaning construction must be sufficiently advanced prior to the Term 2 opening.

The below attached WBS represents a 3-level breakdown of the work packages on the project. This activity has been performed in conjunction with the estimator’s breakdown to provide an accurate basis for planning the project.

The WBS dictionary entries detailed below provide detailed information for each work package, aiding programming, and cost estimation activities. The major input to this process is expert knowledge, often involving people from the entire project team to ensure dictionaries are accurate.

2.1.4

Early Works - Piling

3.1.1 Main Works – Bulk Earthworks

Install secant piles to perimeter of excavated site.

1. Surveyor to set out pile center line

2. Piling rig to be brought to site

3. Piles to be bored over center line

4. Piles filled with reo cages and concrete

5. Secondary piles bored and filled.

Remove bulk material around site, approx. 45,000m3

1. Machines to be brought to site, including rock cutting attachments

2. Set out to commence, also using GPS capabilities

3. Excavation and cart-off of VENM to commence

4. Regular checks of excavated depth and area to be performed

4.1.2

External WorksLandscaping

Install hardscape, plants and associated benches, railings etc. to external areas

1. Hardscape detailed excavation, set out and reinforcement place to commence

2. Concrete pour to hardscape

3. Planting areas to be laid out manually

4. Soil and mulch to be laid

5. Plants to be placed as per drawings

$110k Allocated

Key Dates: MBT Handover: 13/5/2022

Piling Begins: 24/7/2020

Piling Finishes: 19/8/2020

Access to site area is unimpeded for piling rig

Surveyor set out is assumed to be correct

Piling activities contingent on concrete curing time for primary piles

$6.2M Allocated

Key Dates:

Bulk Starts: 11/3/2020

Detailed Excavation Begins: 19/9/2020

Pad Footings Commence: 20/11/2020

$90k Allocated

Key Dates: MTH Completion

Date: 11/5/2022

Landscaping Commences: 29/3/2022

Machines can be delivered to site via trucking routes without issues

Ground conditions are as per Geotech report

Installation meets drawings and required specifications

Installation is certified by structural and geotechnical engineer

Installation meets Australian Standards

Installation meets drawings and required specifications

Excavations must be certified by Civil/Geotechnical engineer, verifying depth and accuracy of cut

Excavation from others is correct and to appropriate depths, requiring no extra fill

Plants etc. will be procured early and available at appropriate time

Installation meets drawings and required specifications

Hardscape installation must be approved by Architect, and Landscape Architect must inspect planting

Scope validation is the process of assessing deliverables, and formally accepting them. This process occurs at both the head contract and subcontract level. Deliverables are generally verified by the builder, as well as third party consultants, before being passed on to the client for final approval.

This process occurs continually throughout the construction of the building, in several ways. Firstly, the builder expects the client to have engaged a QS to validate the builder’s progress claims. This means with each monthly claim, proof of works being completed must be submitted – through photographs, dockets and physical site walks.

Further to this process, the client must formally accept completed parts of the product. Generally, QA documentation is handed over throughout the construction cycle, evidencing correct installation, which is reviewed by a third-party consultant. The client also expects contract requirements to be met – such as BCA compliance – for which approval will be sourced by the builder and passed on to the client as proof of works being completed to required specifications. The same occurs for the Greenstar requirements at Meadowbank TAFE – by the builder meeting all required criteria, the award of a 4-star Design and As-built verification is a method of communicating to the client that these criteria have been met.

Finally, the client and their representatives will progressively review works (often monthly), raising any defects where they believe the product is non-conforming, and therefore formalizing acceptance of the final product. The client may enter the site at any time for an audit or inspection when desired. Payment of any retention to the contractor/builder at the end of the warranty period marks the completion and close-off of the project for the builder.

Subcontractors generally have scope validation requirements written into their contract, generally consisting of producing a defect-free outcome, and meeting all required standards and specifications in delivering their works. Like the head contract, payment of any retention signifies that works have been completed defect-free, that the warranty period (generally 2 years) has finished, and the subcontract has been closed.

Subcontractors also have obligations as to QA and record keeping. ITP’s must be submitted by the SC for each portion of the works completed, and where necessary third-party certification must be shown. Using the example of a scaffold system, the scaffold contractor will usually be contracted to provide their own engineering sign off for any scaffold structures, and these sign offs must be presented to the builder as evidence of works being completed to scope and contract conditions.

Subcontractor Completes Work Package/Subpackage

• Any and all deliverables associated with the task are categorised

Head Contractor inspects the work for defective or noncompliant output

• These defects are logged against the work package in management software

Subcontractor moves to rectify defect, or Head Contractor rectifies on their behalf if not possible

• Monies withehld from subcontractor where relevant.

Deliverables move to Head Contract scope validation stage, detailed in Quality section.

• Refer Section 8 Quality Management Plan for further information

Scope monitoring and control generally comes from the project team having a strong understanding of the drawings, and the quality and completeness of said drawings. A contractor will generally not price a job when drawings are less than 80% complete; this reduces their risk for scope changes.

Throughout the project lifecycle, the best way to minimize risk from changing scope is to push risk onto subbies in Subcontract documents; however, prior to this transfer of risk, RFI’s etc. are an ideal method to gain understanding of the drawings and any detailed requirements.

Scope change is primarily managed through several mechanisms in the Head Contract. While the principal is entitled to make changes, these must be notified to the Contractor in writing, and the Contractor must submit an estimate for the fair value of the extra-over works on a cost-plus basis.

In general, scope changes are managed through the Change Management Plan. This includes steps to assess the changes and price them, then (in the case of the Meadowbank project which is Design & Construct) the Contractor will issue an instruction to their consultants to update project drawings.

1. Change request initiated by Principal, or Head Contractor. This must be in writing and via Aconex or other approved communication channels. Variation agreement is drafted.

2. Project Manager and senior management team assess the change request and prepare formal notification to the client of time, cost and other impacts.

3. All project team members are notified, as well as Subcontractors where necessary. Additional works will be communicated through project documents such as drawings, and may result in subcontract variations.

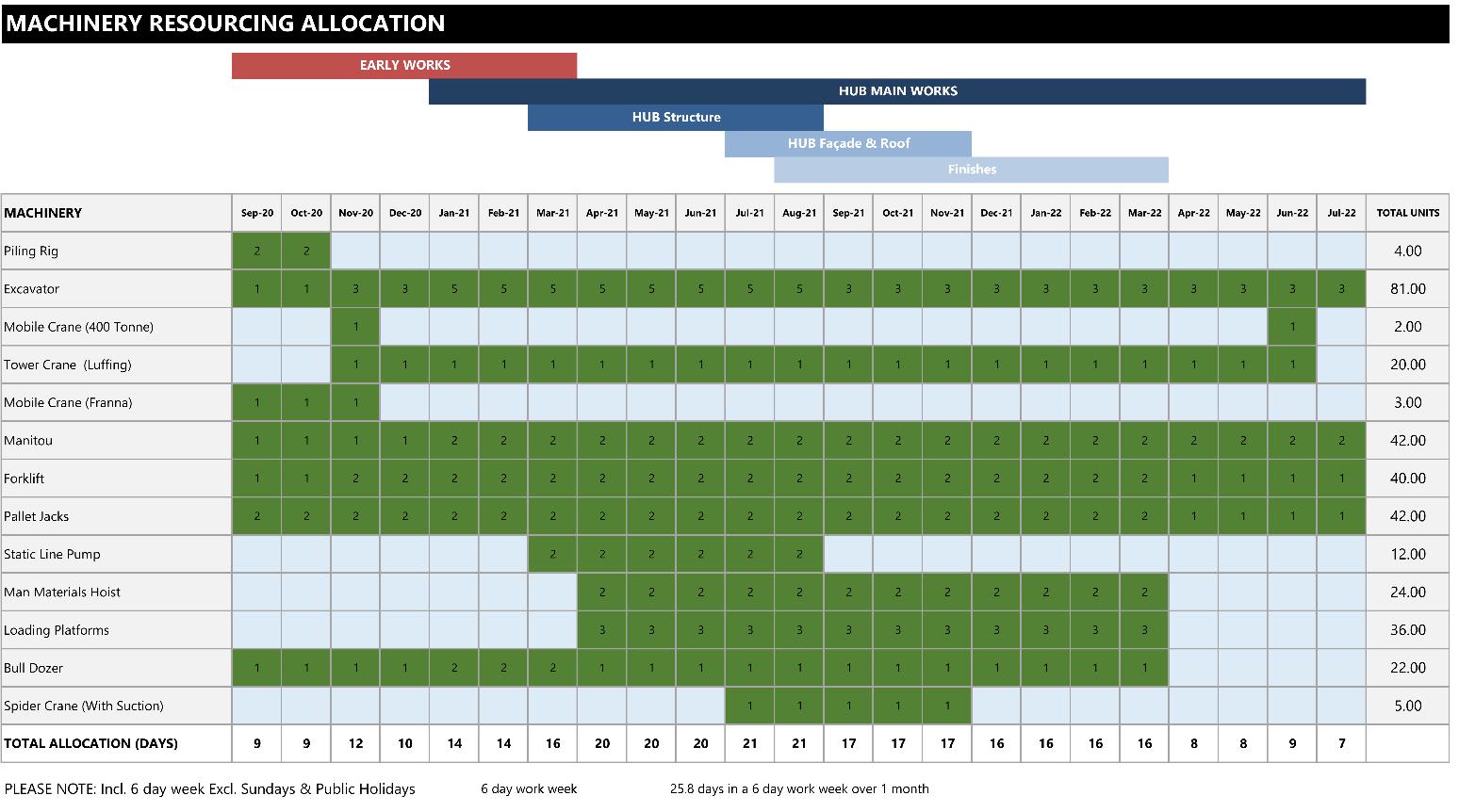

As part of our detailed assessment and preparation to accommodate the principal’s project requirements a comprehensive design and construction programme has been developed to schedule the successful delivery of the TAFE project.

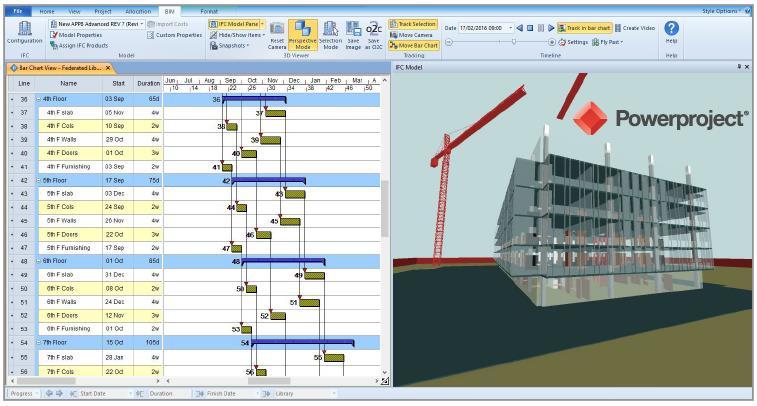

We are committed to being at the forefront of technology. Throughout the preconstruction and delivery phase, we have and will continue to look to utilize 4D BIM models produced for the project to assist in the analysis of the proposed methodology and address any challenges associated with the buildability of the current design. These BIM models are linked directly to the programme, adding the element of time to the model's geometry, providing the team with a visual approach to planning in the form of a 4D BIM simulation.

The 4D BIM model and professional expertise of the project team are the key assets relied upon to create the project schedule. A PERT analysis will be undertaken with the broader team to ensure a detailed review of the program and enable iterative reviews. This will then feed into a standard refined CPM schedule model.

The following scheduling tools and techniques were used to develop the project program:

Our highly experienced project team truly sets us apart from our competitors, ensuring the project is completed on program. The project team is the driving force behind the integration of our refined program/schedule management processes that promote collaboration, management, and consistent refinement of the program throughout the project lifecycle

The critical path within the program has been clearly identified. Critical activities have been highlighted and bordered in red, whilst activities with float attached have been illustrated in blue. Critical Milestone and Phase Planning Workshops are being undertaken ahead of time, these workshops require the involvement of the entire project team, key consultant representatives, trade supervisors and suppliers to ensure a coordinated and accurate execution of the programme Throughout the TAFE project, Critical Milestone and Phase Planning Workshops are being conducted for the civil works, substructure works, structural frame, façade, services, fitout and throughout handover and commissioning

The project team have relied upon an extensive Historical Data library that identifies lessons learnt regarding scheduling for previous projects similar in nature. The Historical Data allows for a well-

informed approach to program methodology and highlights potential delays or issues that need to be considered throughout the project lifecycle when developing the program.

The Project Team are committed implementing strategic Resource Levelling which involves shifting program tasks that do not impact the critical path, the amount of shift is determined by the tasks float. This is done to reduce the stress on resource and optimise productivity

The 4D BIM Modelling Illustrates the project’s construction methodology and key construction intervals to demonstrate the progress of the construction works at nominated stages. The BIM model provides a visual and interactive tool that allows for deep understanding and critique of the construction methodology 4D BIM Modeling is highly effective when detecting clash detection, The model provides a visual reference for project progress which not only benefits our project team but the projects Stakeholders who are not familiar with the technical intricacies or stages of construction

The Project Team has implemented PERT throughout the development of the project program and its operation throughout the duration of the project. PERT highlights the likelihood of on time programme completion whilst simultaneously tracking project progression. PERT will be checked by the project manager on a regular basis to ensure the project is meeting set milestones and the overall program health.

Fig. 7: An example from the Powerproject software showing 4D capabilities

A comprehensive project program has been produced to the industry standard Gantt chart layout. The program was developed using Asta Powerproject, integrating 4D BIM modelling and project team expertise as guidance and reference. The three level WBS informed the first stage of program creation, followed by in depth workshopping with the Construction manager, Project Director and Project Manager.

The program development process consisted of clearly identifying all major activities, milestones and dependencies that were determined to provide the most efficient delivery of the project. Critical Phase Planning Workshops are undertaken ahead of a critical phase of the project and include the involvement of the project team and key members of the consultant team, trade supervisors and suppliers.

For the TAFE project, we will hold critical phase planning workshops for civil works, substructure works, structural frame, façade, services, and fit-out related trades to identify critical tasks and required deliverables for completion in relation to the projects schedule baseline. The critical path is clearly identified. Critical activities have been highlighted and activities with float attached have been illustrated.

The method undertaken to estimate the projects activity durations revolved around integrating project workshops, historical data, consultants advise and project team expertise. Tracking activity duration from previous projects enables accurate schedule related estimates to be proposed. Drawing upon the historical databases of similar projects average time for completion can be established for various schedule tasks such as concrete pours, formwork stripping or waterproofing. Weekly Project Team schedule review meetings assist in the active management and maintenance of the project program as the works progress in real time. The Project Team will also involve the key trade representatives to provide feedback and status updates on ongoing and future works

The key theoretical method used for the project’s activity sequencing is CPM (critical path method). All standard logical connections are used, as per standard CPM practice. These connections include finish to start, start to finish, finish to finish and start to start. All floats have been calculated and included.

Significant time has been allocated to ensure coordination between services, finishes and fitout has been sequenced and integrated into the program ensuring smooth and predicted progression. Where plausible the Project Team has integrated time allowances for prefabrication of components off site into the program. This facilitates efficient installation and increased quality control, ultimately leading a more efficient program and de-risking time-dependent components.

The construction methodology for the TAFE considers the building as two independent structures, with the North structure separated from the South structure by the central atrium. This approach to the construction methodology allows for optimization of the schedule through strategic sequencing of multiple trades and tasks. This is reflected within the internal fit-out which progresses between the two buildings without being required to wait for individual floors to be completed as other trades move through. Concrete pours have also integrated breaks and sequencing to optimise program efficiency This slab on ground pours which will follow the completion of the detailed excavation start from the higher levels and progressively work down. Following the completion of civil and bulk earthworks, the HUB structure will commence.

The following (page over) schedule/ program baseline is the final approved version of the program model. We recognise the schedule/ program baseline document as extremely important to the projects time management as it governs the projects overall estimated timeline, milestones, and critical path.

The elected Progress Measurement process for monitoring and assessing progress made within the project’s program will be a milestone-based progress measurement system. The TAFE Project program when loaded into Asta Powerproject has a total of four milestones that have associated percentages of completion related to them. As the project progresses and scheduled tasks are completed the percentages of completion will increase and subsequently provide a reliable and consistent progress measurement system for monitoring and control purposes.

In total the gross project duration undertaken by the head contractor will be 21 months. The main project milestones are listed below.

Main Contractor Appointment 06/04/20 113d 19/09/22

ECI Phase 28/10/19 275d 04/12/20 Procurement 18/11/21 369d 18/11/21

Appointment

Procurement Substructure Civil 16/09/20 26d 23/10/20

Procurement Superstructure Roof Coverings 28/10/19 67d 13/08/21

Procurement Superstructure Roof Safety 18/11/21 62d 13/08/21

Construction Phase Early Works (Phase 2)HUB Tree Clearing 14/10/20 10d 26/10/20

Construction Phase Early Works (Phase 2)HUB Civils 23/010/2 0 85d 26/02/21

Construction Phase Early Works (Phase 2) Completion 26/02/21 10d 12/03/21

Construction Phase Main WorksHUB Structure 13/02/21 137d 20/08/21

Construction Phase Main WorksHUB Structural Steel 29/06/21 56d 09/09/21

Construction Phase Main WorksHUB Formwork Strip 16/06/21 46d 14/08/21

Construction Phase Main WorksHUB Façade & Roof 07/07/21 108d 29/11/21

Construction Phase Main WorksHUB Finishes 28/07/21 169d 25/03/22

Construction Phase Main WorksHUB Handover 18/02/22 82d 10/06/22

The Project Team will undertake weekly programming and upcoming task planning meetings where progress status is updated. This will require the update of tasks, resource availability and cost. Monthly management meetings as well as PCG meetings will be undertaken to review and manage the program as the project progresses.

Key Project Milestones Considered.

Project cost management is the cyclical and continual process of ensuring costs for a project are tracked, understood, and forecasted such that the project team and project manager have a firm understanding at any moment of the financial performance of a project. The overarching aim of any cost management process is the same as the key aim of the project, and of the business – to deliver a profit.

This section will discuss cost management processes which occur at a project level, where the project manager is then responsible to upper management for cost performance. When understanding and planning cost management, all facets of cost must be considered - from client facing costs such as progress claims and variations, to all internal monitoring of spending against budget, ETC, EAC and graphical measures - such as PV, EV and AC. When used accurately and holistically, the following processes will aid in delivering a successful, profitable project.

Cost estimation is the crucial preconstruction process of estimating and breaking down the costs for the project in a holistic sense, to obtain a price suitable for bidding on the project. An unprofitable project delivers no benefit to a business or its shareholders; thus, accurate cost estimates are critical in the early stages of any project.

Following this, an estimate must be made of the approximate costs of the project, to bring together a tender. An estimate for the TAFE project is to be prepared in two stages: an initial high-level ‘cost plan’ will be created to aid with deciding on the feasibility for the builder to undertake the project. The second step, which comes when the Main Works for the project are being officially tendered, is to create a detailed cost breakdown/estimate. This information is used not only for the builder to plan the project and their profits, but to present a final price to the client (TAFE).

A cost plan is an initial estimate of the cost of a project, created by a builder as a preliminary screening method. This can be put together rapidly, and once created, the high-level cost plan can be given to senior management to allow them to make a decision on whether to proceed with the project/tender or not. The cost plan may be put together using the following methods:

• Initially, an analogous estimate may be made. This is a top-down estimate and looks at approximate costs based on previous similar projects. An analogous estimate can be created in minutes and allows for instant understanding of the project.

• More advanced techniques can then be used to refine the cost plan. These may include parametric estimates – where historical data on different work packages is used to generate

costs, or a three-point estimate – where existing data points have an uncertainty and risk factor added.

Following the initial ‘go’ or ‘no-go’ decision by senior management, a detailed estimate can be created as part of producing a tender or bid for a project. This is put together by the estimating team as follows:

• Firstly, using the project programme, a cost breakdown structure is produced as subset of the WBS. This allows the team to view all related costs – such as preliminaries, council compliance, subcontract work, and commissioning costs.

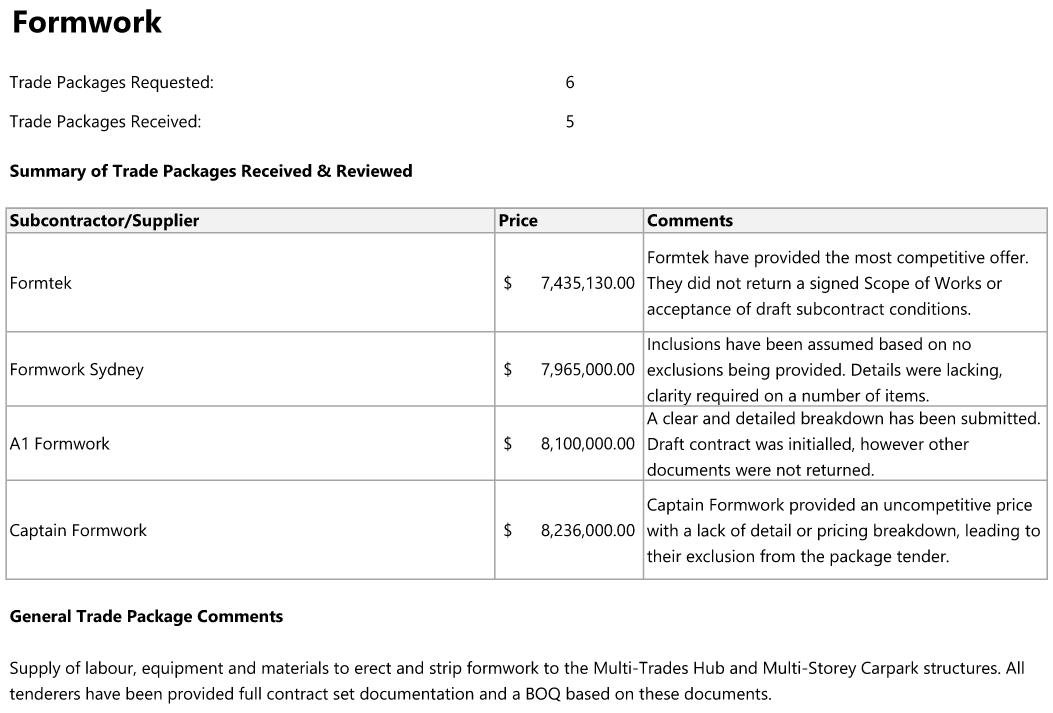

• Following this, the estimating team will perform a take-off from the drawings, and issue these to subcontractors to receive market prices for sections of the work. Tenderers are selected based on their capability and experience in delivering similar projects, along with their ability to work with the builder on safety, quality, time, and environmental requirements. An example of this quote comparison process for the TAFE is given below:

One critical step in creating the budget is to review the estimating work done to date and identify opportunities for Value Engineering. These decisions are made in tandem with the client and designers throughout the ECI phase and allow the builder to have input of the design as it is developed, ensuring opportunities for savings in construction are realized. Examples of VE elements may include:

Value Engineering Item 1: Carpark Innovation - $4.8M

- Original design documents for the project show the carpark constructed below the new Multi-Trades Hub, requiring significant excavation and extra structural works to complete. The builder has proposed an alternate carpark be built separately, in a different location on campus, saving time and cost for the client.

Value Engineering Item 2: Skylight Reduction by 25% - $400k

- On consultation with the architect and client, the decision was made to reduce the total skylight area. While still allowing large amounts of natural light, and meeting design criteria, the reduction represents a significant saving for the client.

Finally, with the aid of senior management, margin and contingencies for the project will be estimated. For the TAFE project, a standard margin approach of 5% has been utilized. Included in this process is the inclusion of contingency; this is an allowance for risk, and is intended to allow for weather conditions, interest rate changes, force majeure events (e.g., Covid) and material price fluctuations. A key example of this would be changing steel prices, an issue the industry is facing at the current time. As tender discussions progress, these contingencies and profit margin may be reduced – this occurs to improve the chances of the builder winning the work and is done so at the discretion of senior management.

In the case of the TAFE Multi-Trades Hub project, the builder is contracted on a design and construct basis. This means any budget estimate is made at tender time under the premise that design is to be developed further. As such, design risk and cost change risk fall on the contractor, and therefore budget movement is inevitable. This process is discussed further in the cost control section; however, it must be noted that the final Cost Breakdown Structure below is based on a design that is only 80% developed –and further changes must be managed to be cost neutral.

See below detailed cost breakdown structure, representing the makeup of work packages for the project. This is to be read in conjunction with the Work Breakdown Structure, and below high-level cost summary.

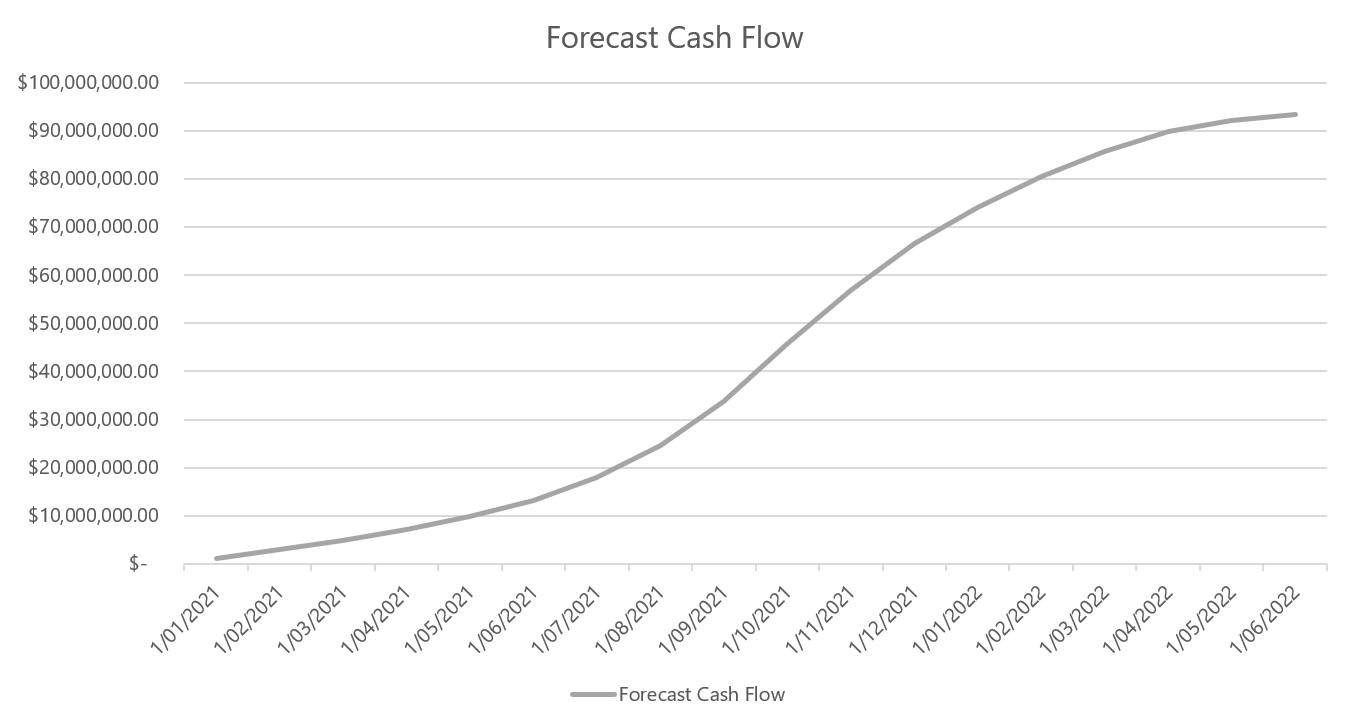

Planned Value is a critical foundational project control measure, established to ensure monthly progress claims and cash flows are suitable to ensure a positive revenue stream for the business. This diagram essentially represents a project-level forecast for the cost performance of the entire TAFE development, and allows the project team to accurately predict and manage cash flows where necessary.

As the Meadowbank TAFE Multi-Trades Hub represents a single building; relatively traditional construction method, cash flow forecast closely match the average ‘S-curve’ shape.

Head Contract Administration

Responsible: Project Manager, Senior Contract Administrator

• Manage monthly progress claims and substantiation, aiming for a consistent cash positive position.

• Maintain communication with client via monthly coordination meetings.

• Update project baselines, including programme, cost baseline, variation register and design departures to reflect progress

• Notify the client formally when required – e.g. Extension of Time, Delay notices

• Have a strong understanding of risk allocation within the contract – for example, an understanding of which party holds latent conditions risk, or float risk in the programme

Subcontract Administration

Responsible: Senior Contract Administrator, Contract Administrator, Cadet

• Progressively let subcontracts for the entirety of the works.

• Manage and control progress claims, ensuring SOPA conditions are followed, and ensuring scope is being met by the subcontractor.

• Issuing back charges where relevant if SC’s fail to meet agreed contract conditions or programme.

Ordering and Purchasing

Responsible: Contract Administrator, Cadet, Foremen

• Raise Purchase Orders for all minor expenditure, ensuring continual costs are being tracked and forecast where necessary

• Report on purchasing related to preliminaries to ensure expenditure is kept under control by the project team.

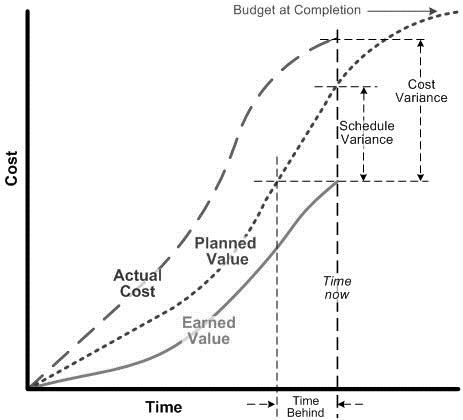

Cost performance measurement is concerned with the tracking and forecasting of the project’s financial performance over time. At a high level, costs can be tracked using earned value measures. These methods consider several critical project measures; work completed as per schedule; milestones met; and money spent to date. Thus, a graph can be created which displays all these factors and provides a

visual aid as to the progress of the project. This can be compared to a baseline to track progress. Essentially, EVM measures project performance over time.

EVM measures form a key component of both the Head Contractor’s internal reporting, as well as client reporting, PCG meetings etc. Measures such as the Cost Performance Index and Schedule Performance Index will be used for client reporting; these captures varied unique pieces of project data in a summarized, communicable nature. In order to create these measurements, initially Planned, Earned and Actual values must be determined. Planned value and Actual value form component of monthly forecast reporting and are therefore already understood. Earned Value, however, must be calculated. This can be done in several ways; namely:

At the builder’s level, these measures are conducted and reviewed on a regular basis (usually monthly, matching SOPA monthly payments) such that the project team can review and account for progress to date. Along with additional tools such as Staff Plots and schedule baselines, schedule, cost, and their respective performance indexes can be scrutinized.

As part of the natural development of a project, at times performance may differ from the desired baseline. This may come in the form of exceeding schedule or cost performance limits. If these concerns are raised to the client, in the case of the TAFE, initially a review of contract conditions would take place to ensure the principal is protected against issues caused by the contractor.

On the contractor’s side, the processes in place around such an issue would involve crashing schedule or adding financial resources to the project. This would allow works to sped up if necessary, employing extra over labour. This may mean the project is in a negative or weak cash position, however these measures may be necessary if they avoid greater issues under the head contract. In the scenario of the Meadowbank TAFE, no major issues with cost or schedule tracking have been reported yet.

Cost monitoring and control is proactive and is used to predict the outcome of a project based on actual costs, which allows preventive or corrective actions to avoid variations in final cost.

• A reduction in scope (e.g., removing a portion of landscaping works) will affect the total contract value, and thus reduce the overall cost of the project and therefore potential profits for the builder. This scenario is generally avoided by builders.

• A change in scope such as reduction of a provisional sum may however have alternate effects under the GC21 standard head contract. Here, if a share of savings contract has been employed, while the contract sum will stay the same, both the principal and contractor may stand to benefit from an increase in share of savings.

Cost variance response is a process triggered by project control measurements moving outside of an established range. If either SPI or CPI (previously identified) are to shift outside of allowable bounds, a cost variance response is required to correct the issue and ensure contract conditions are met. When variances for either figure are between 0.1 and 0.2, this identifies a minor issue, that requires internal adjustments to ensure the project continues tracking to plan. When variances exceed 0.2, a crucial error has occurred which must be reported to management and requires urgent action.

In terms of PCG reporting to the project sponsor, CPI and SPI also represent critical measurements used to communicate project progress. When a variance occurs, which exceeds contract allowances (>0.2 away from unity), the Principal must be notified in writing. As per contract conditions, the Head Contractor must provide in writing a plan to remedy the issue (corrective action), within 7 days of notification. This must be treated as an internal variation, and any associated costs are to be mitigated where possible. These actions are detailed as follows:

Individual trade package variances (as per Head Contract BoQ) of less than 10% are to be absorbed by the Head Contractor, and must be notified internally

Variances (either positive or negative) of greater than 10% must be reported to the client, with a formal variation request provided if necessary.

Variances greater than 25% become the sole responsibility of the client, and represent a deprture from contract scope, away from contingency allowances etc.

When amendments arise from the client’s request to project deliverables or scope, these may trigger a Head Contract variation. Generally, considering a design and construct contract, minor changes or updates to design are to be captured in the Head Contractor’s scope, falling under the responsibility to complete design documents and capture design intent. However, when changes fall outside of the original design intent, the Head Contractor must comply with the client in delivering a formalized variation and associated pricing.

• Initially, the Project Manager should utilise schedule and work performance data to verify the work performed to date. This can be compared against relevant baselines.

• Next, the PM may review funding sources for a large variation. They will likely review:

o Cash-flow (present and future), to verify that cash is available if any significant costs need to be incurred rapidly. Shortfalls identified will allow escalation.

o Consistent forecasting must be reviewed to ensure large payments in the short term are not upcoming. If not identified, these payments could potentially severely impact the cash position of the project and make rapid adjustments difficult.

o All of the above should occur on an ongoing basis, but specifically reported and finalized monthly when presented to senior management. Adequate resources must be deployed for forecasting.

• A formal Request for Cost Change can now be submitted internally to the PM. This will detail all associated costs and baseline impacts for their approval. A change with greater cost and time implications may be forwarded on to Senior Management.

• If approved, the change must be logged, communicated to the client and then all baselines must be updated (schedule baseline, cost baseline, performance measurements).

Considering Meadowbank TAFE’s D&C Contract type, the Head Contractor has a responsibility to proceed with changes that align with the design intent and represent a cost neutral approach. This is component of their commitment to continue design and consultation from the Developed Design phase to IFC documents. This process workflow is as below:

RFI is sent to the client (via Aconex), including Superintendent in correspondence.

Client responds to RFI with direction. If captured by design intent, changes to be included in drawings at no extra cost.

If requested changes go beyond the design intent, a formalised variation is prepared by the Head Contractor. Advised to Superintendent.

Superintendent will issue a response in coordination with the Client, issuing a site instruction or formal acceptance of variation and instruction to proceed.

Head Contractor to complete the works, updating baselines where necessary to communicate to Superintendent. Any risks from this point are to be allocated as per Head Contract agreement.

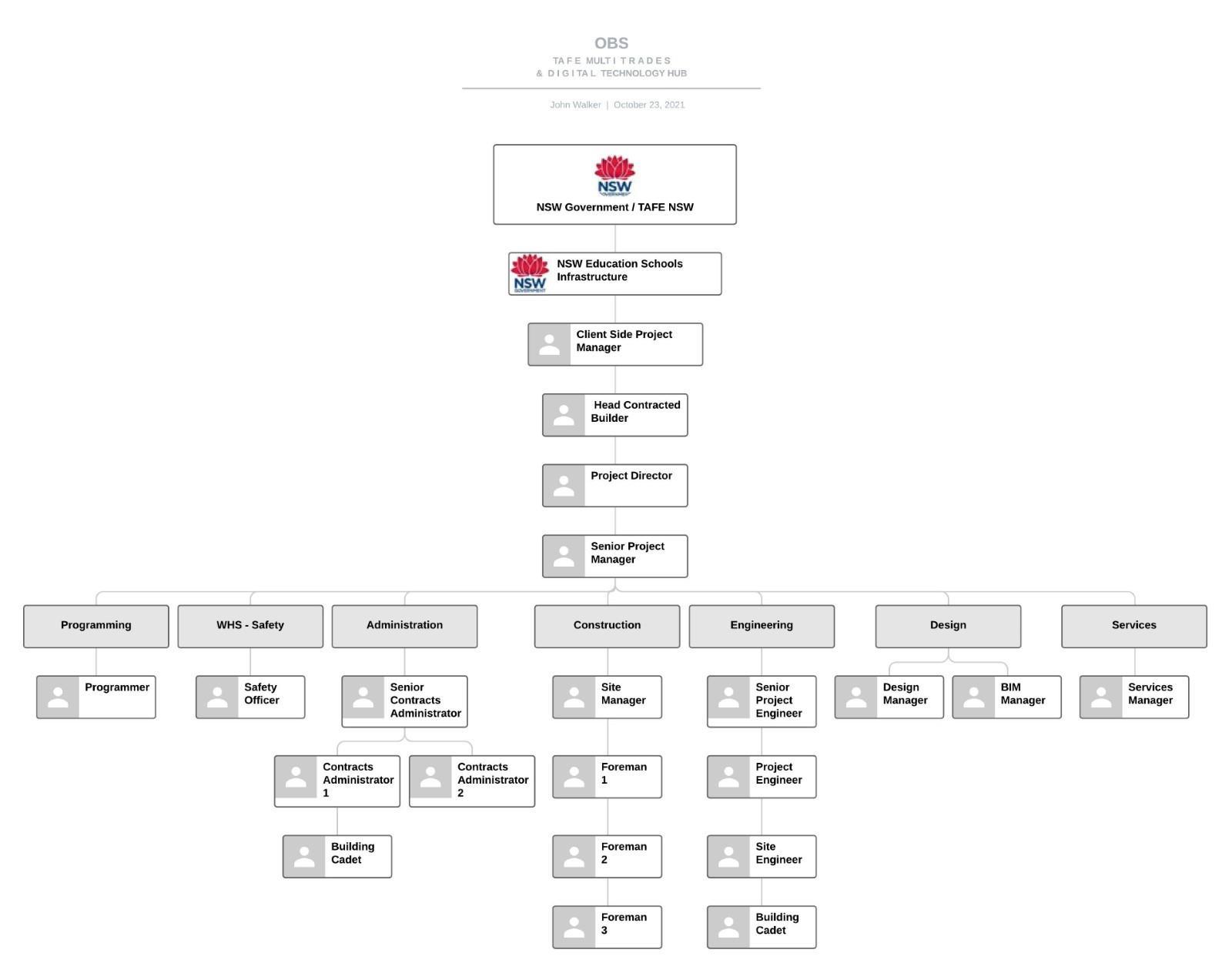

Organizational Breakdown Structure (OBS) is a depiction of the project organization hierarchy that aims to highlight the projects responsibility and reporting structure. Please see our organization structure currently implemented for the project.

Project Director (PD):

Works closely with clients from the outset to understand required project outcomes, overseeing all facets of the project to ensure successful delivery. Maintains positive relationships with clients to guarantee project success and provides ongoing leadership to the team across all disciplines.

Key Skills:

- Achieving Client Outcomes

- Budgeting

- Programming

- Leadership

- Planning

- Interpersonal Skills

- Negotiation

- Veteran Project Experience

Senior Project Manager (SPM):

Responsible for the overall delivery of the TAFE Technology HUB Oversees and manages key aspects of the project such as the programme, budget, and quality. The PM oversees the evaluation and development of the projects reporting, approvals, and performance of both the project team and subcontractors.

Key Skills:

- Budgeting - Programming - Leadership - Planning - Stakeholder Engagement

- Interpersonal Skills - Negotiation - Extensive Project Experience

Senior Project Engineer (SPE):

Providing immediate support to the Project Manager in managing the project in accordance with company policy and procedures. The Senior Project Engineer oversees and manages a team of Project Engineers and Cadets, allocating tasks and deliverables accordingly. The Senior Project Engineer aims to

ensure the projects successful and timely completion and to achieve objectives for quality, time, safety, environment, profit, and client satisfaction. This can include document control, quality control, program statusing, defect rectification, chairing design and authority meetings, liaising and negotiating with subcontractors and being responsible for RFI queries.

Key Skills:

- Administration

- Planning

- Quality Control

- Programming

- Defects

- Design

- Interpersonal Skills

- Project Experience

Senior Contracts Administrator (SCA):

Responsible for the overall administration of the project whilst providing immediate support to the Project Manager in overseeing responsibilities such as the preparation of subcontract packages, scope of work, procurement schedules, issue of variations, budget related administration and the coordination of site meetings and workshops. The Senior Contracts Administrator oversees and manages a team of Contract Administrators, allocating tasks and deliverables accordingly.

Key Skills:

- Contracts Management

- Building Code Compliance

- Subcontractor Engagement

- Reporting Analytics

- Interpersonal Skills

- Negotiation

- Extensive Project Experience

Responsible for the projects site operations monitoring and controlling related time and cost factors. The Site Manager oversees project progress and is responsible for the site teams safety, quality control and leading the operations onsite. The Site Manager oversees and manages a team of Foreman, allocating tasks and deliverables accordingly.

Key Skills:

- Programming

- Defects

- Project Delivery

- Site Coordination

- Site Awareness

- Knowledge of Construction Processes

- Attention Detail

- Subcontractor Management

- Interpersonal Skills

- Project Experience

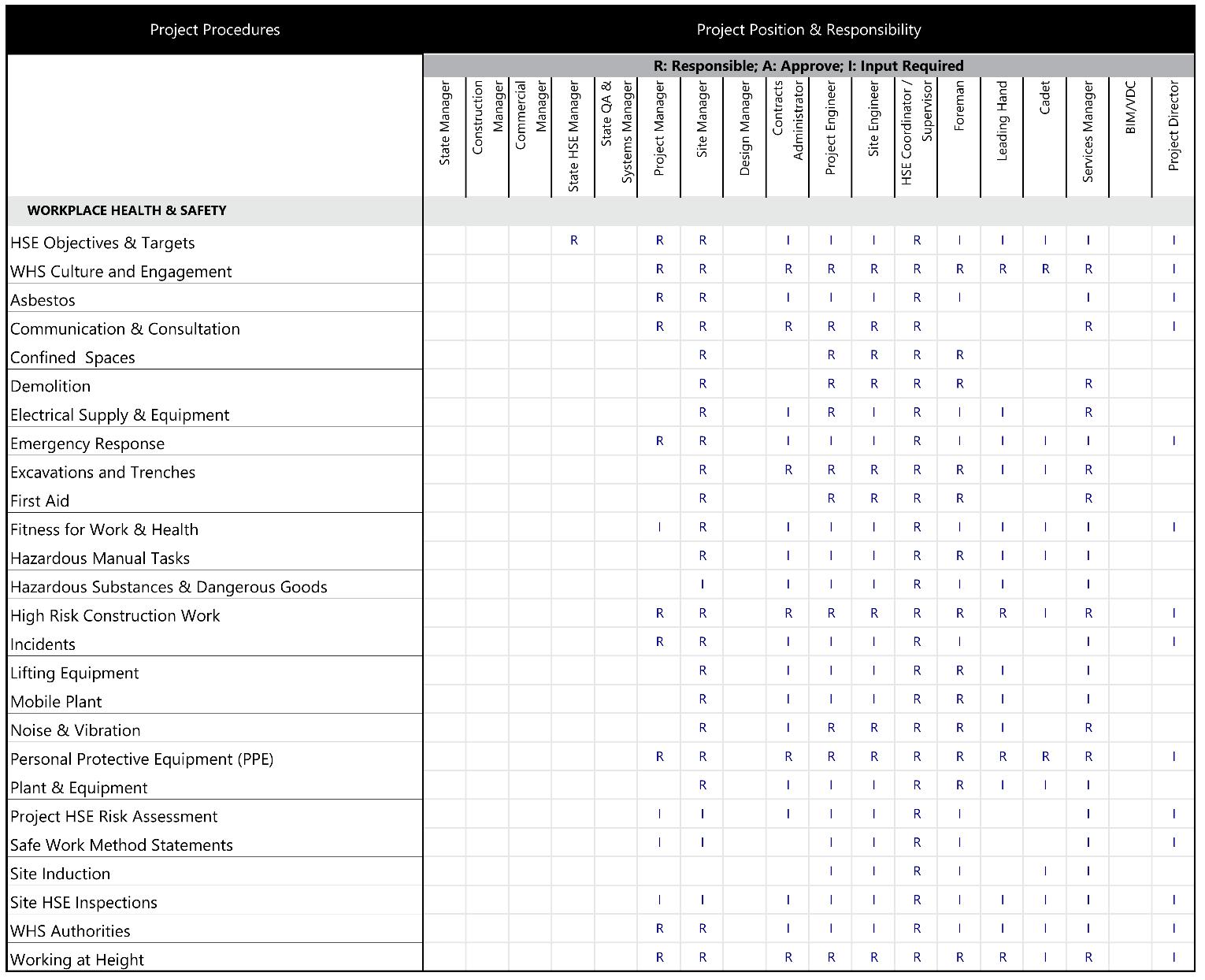

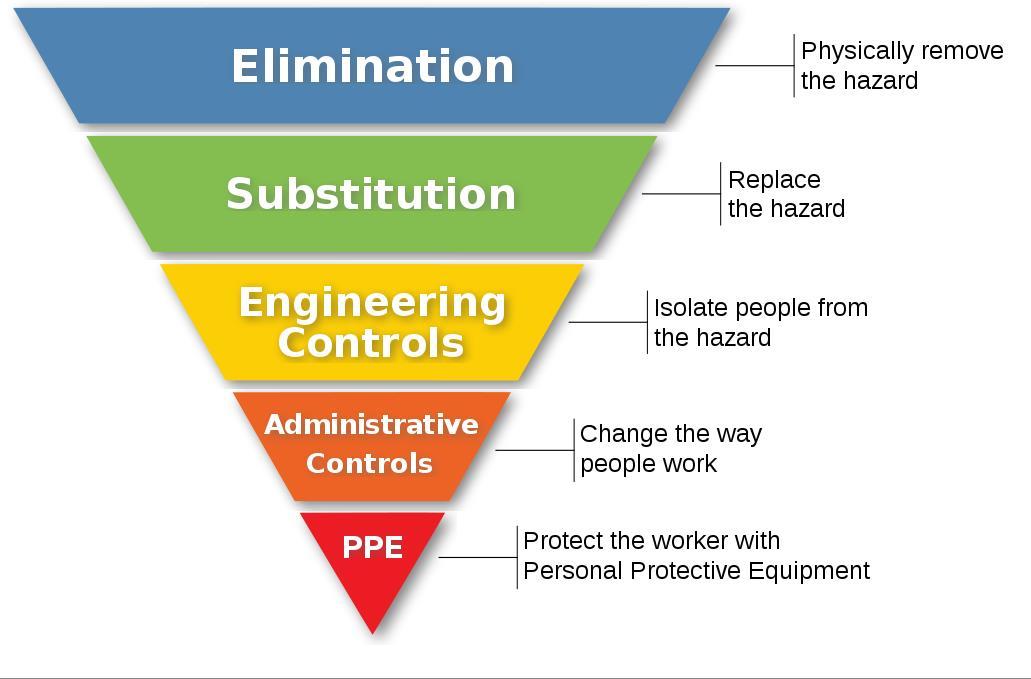

Workplace Health & Safety RACI

THE YTB Release plan is implemented as a key milestone or project is reaching completion. Staff will be given extensive notice when the end of a particular task or project is reaching completion. Contracts will be offered to project team members who have performed throughout the duration of the project. HR will be involved extensively in the review and support of staff. Project team members who are not carried through with the company will follow due process outlined in the YTB standard employment contract.

Total Days Worked by Role

Any individual entering the work site with the intention of completing works must have a registered white card, they must also undergo the site induction process and answer all questions required through the BIM360 onboarding process. A member of the project team will complete a walkthrough with the inductee highlighting key locations of access, exit and evacuation points, first aid and nurse call locations Induction

12. Site Housekeeping & Security

13. Unexpected Finds Protocol - Heritage 14. Construction Parking and Worker Transportation

15. Code of Conduct

16. BCA – Building Compliance 17. NSW Codes Practice

Specialised task training looks to target safety induction information to personnel operating specialised or heavy machinery and workers undertaking high risk works. These individuals will be taken through additional safety measures by a project team member.

Visitors will be required to sign in at the site office, from there they will be issued with PPE and accompanied by a member of the project team throughout their visit to the site

YTB Constructions Measures project performance through the calculation of labor productivity, site population and programme comparisons. This is derived from the following:

- Man-hour ratio >100% (Monthly man-hours / Planned man-hours)

- Baseline Programme vs Status Programme Dates

- Productivity index > 105 (Final contract sum / Total man-hours)

The current staff recognition and rewards plan actively creates incentive for our site teams to strive for excellence throughout the lifespan of the project.

Performance Incentive Bonus Requirements:

- Outperforming Allocated KPIs

- Meeting programme milestones on time and to scope

- Meeting Quality Requirements

1.1.2

1.1.4

At YTB Constructions we prioritize gender equality. We believe in equality of opportunity for all our employees based on merit, regardless of gender. YTB Constructions are proud to have 50% of our executive leadership represented by women We pride ourselves on our commitment to providing everyone with equal opportunity, regardless of their ethnicity. At YTB Constructions ethnic diversity amongst our employees spans more than 20 nationalities from across the globe

Our principles surrounding equality state that no unlawful discrimination relating to:

- Gender

- Age - Race

- National

- Sexual Orientation

- Religion

- Disability

- Pregnancy

- Marital Status

- Family Responsibilities

- Political Opinion

- Social Origin

YTB Constructions is a registered Indigenous Enterprise as we have more than 50% Indigenous ownership. We have both Indigenous employees working at Decode and Indigenous enterprises subcontracted to YTB Constructions.

Supply Chain:

- Preference is given to suppliers that are 50% or more Indigenous owned

Subcontractors:

- Preference is given to subcontractors who are 50% or more Indigenous owned. Subcontractors must be Indigenous Enterprises and registered with Supply Nation (supplynation.org.au)

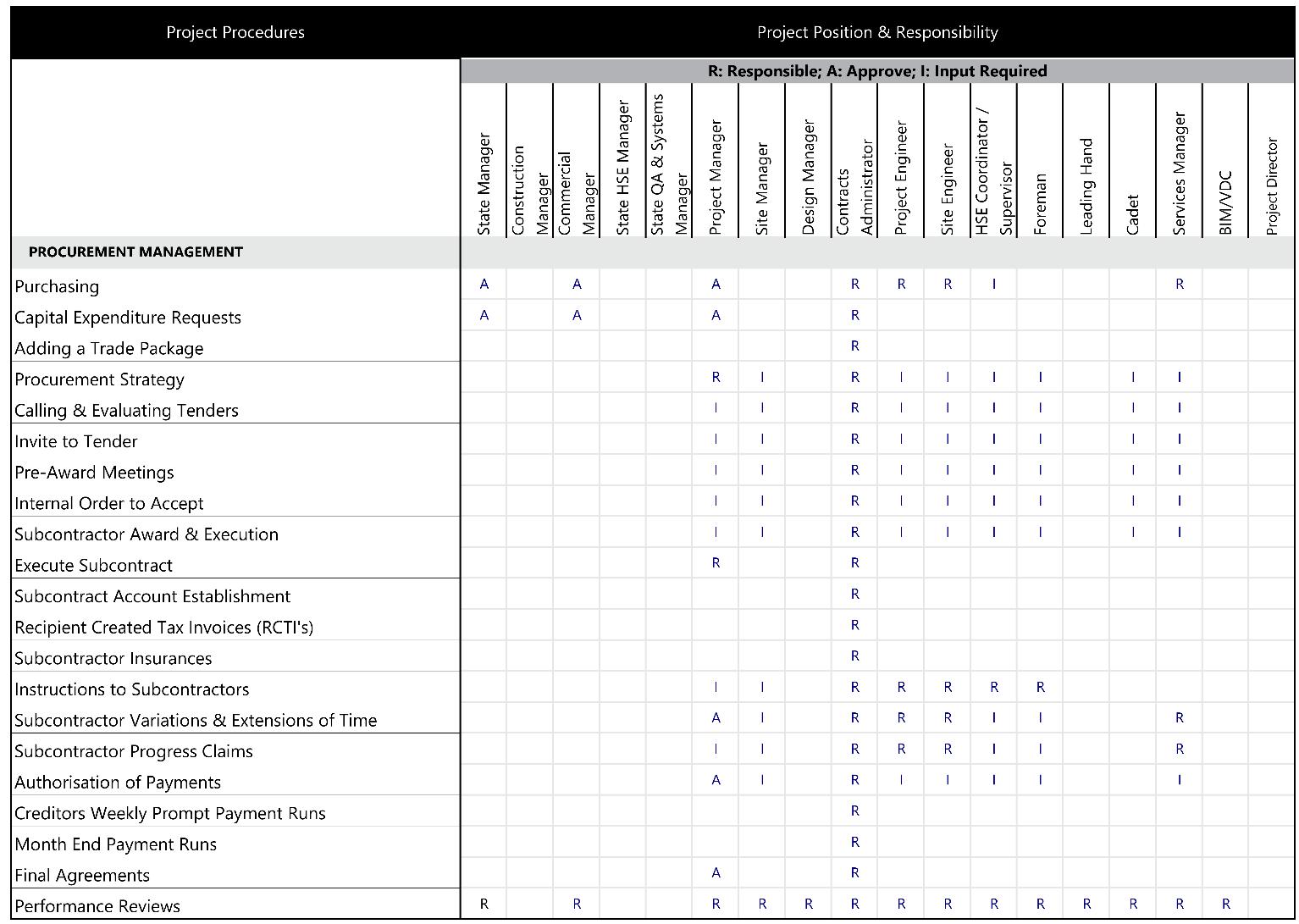

The Meadowbank TAFE project presents a relatively industry-standard opportunity to outline and discuss procurement methodologies consistently used daily in the Australian construction industry, and which fall in line with legal and NCC guidelines. The following guidelines have been adapted from industry standard documents to suit the project specifics.

•The first step in beginning a procurement process is to establish the works to be completed. This can either come from the WBS, program or budget breakdown of the project. A Scope of Works can then be developed internally from these documents, enabling markups and takeoffs to be developed and tenderers to understand the works required. A baseline quantity for the works is established, to compare tenders against later.

•Any risks identified by the Contracts Administrator must be raised internally at this point. These risks are generally associated with discrepancies between the tender Bill of Quantities, and design documents as they exist in the present day. Amendements may be required to ensuresufficieny budget to complete the works.

•With a complete SOW, an invite to tender can be issued. This generally goes to selected prequalified tenderers; these may be companies that are familiar to the project team, or which the Head Contractor has worked with before and proven reliable. All project documents and the trade specific SOW will be issued for pricing.

•Within a short time period (generally 2 weeks), tenderers will be expected to return a price breakdown. This breakdown will then be processed by a Contract's Administrator, into a form such that pricing can be compared with other tenderers. This enables direct comparison across subcontractors, and price-optimal decisions can be made.

•This comparison will be submitted internally to the Senior Contracts Administrator, as well as the Project Manager, for workflow approval. Recommendations follow strict protocols - when a loss or win exceeds a certain amount, increasingly higher levels of senior management are to be notified to ensure no omissions or risks.

•Once the relevant manager has indicated approval, the Contract's Administrator will move to finalise the contract with the Subcontractor. Specific inclusions or exclusions may be discussed at this point, in consultation with the Project Manager. A pre-award meeting is the key component of these discussions - where contractor abilities are assessed against a checklist.

•Once final negotiations are complete, the contract will be issued (generally electronically) to the Subcontractor to be signed, and then countersigned by the relvant manager. This signifies the end of the procurement phase of a Work Package.

In order to easily identify the work packages associated with the project, procurement responsibilities must be organized and broken down to enable Contract’ s Administrators to proceed in line with the procurement management plan. The below package list is in response to the BoQ and WBS, and outlines every identified trade package, and the associated parameters.

Package Contract Type

Description

Mechanical Design & Construct Provision of mechanical services to the building, including design

Electrical Design & Construct Provision of all electrical services excluding high voltage works. Campus works included, as well as temporary construction power

Fire Protection

Design & Construct Design and installation of wet and dry fire services, including commissioning

Hydraulics Design & Construct Design and installation of all hydraulics, include Syphonic drainage to roof

HV Design & Construct Supply and install of all Substation works, as well as HV feeds and commissioning to main building

Civil Works Construct Only Excavation bulk and detailed of all site material, including fill where required

$6,200,000

Supplier / Previous Score

Project Director Immediate JD Projects

Rank Score 7/10

$11,000,000

State Manager Immediate. Some items effected by Covid-19 delays A1 Electrical

Rank Score 8/10

$4,345,000

Project Director Immediate Fire FP

Not used previously

$8,900,000

Project Director Immediate, overseas procurement impacts some items with ordering to occur early Hyd.co

$1,110,000

Project Manager Large quantities of copper required, pending overseas shipping time

$6,000,000

Rank Score 6/10

HV Services

Not used previously

Project Director Immediate JB Civil Works

Rank Score 9/10

Vertical Transport Design & Construct Design and install of elevator systems for the project, including training and handover

Formwork Construct Only Installation of all formwork for all concrete items, excluding verticals

Concrete Place Material Supply Placement of all externally supplied concrete, to all elements throughout

Reinforcement Place Labour Hire

(Schedule of Rates)

Supply of labour to install all reinforcement, externally supplied

Post Tensioning Design & Construct Design and installation of PT reinforcement to structural specifications

Roofing Design & Construct Roofing to entire Multi-Trades Hub building, including guttering

Structural Steel Construct Only Design and construct of structural steel

Façade & Windows Design & Construct Coordinated design and installation of compliant Façade system, including all testing

$945,000

Project Manager Immediate, pending design clarification Schindler

Rank Score 7/10

$4,500,000

Project Director Immediate Captain Formwork

Rank Score 8/10

$2,450,000

Project Manager Immediate Concrete Co Not used previously

$1,900,000

Project Manager Immediate, however pending steel supply shortage EasyReo

Rank Score 4/10

$2,749,000

Project Manager 3 months design PT Designers Not used previously

$1,100,000

Project Manager 1 month design Axis Roofing

Rank Score 7/10

$6,247,000

Project Director 6 months fabrication Steel Leaders

Rank Score 9/10

$13,000,000 State Manager 6 months design and fabrication, including shipping delays A1 Façade Not used previously EquipmentExcavator

Hire

EquipmentGenerator Equipment Hire

EquipmentMobile Crane

Hire

A critical component of the CA process is moving beyond standard package letting and contributing to commercial success opportunities in performing analyses of project financials Positive risks are often identified at the risk management stage; a successful CA can implement procurement strategies to pursue these positive outcomes and provide a beneficial position for the project. Analysis of this is to occur as follows:

1. Initially, a trade package must be broken down to its component parts. This will mean a comparison of finalized IFC drawings with the tender BoQ, to ensure that components have not been missed, and aide in establishing a baseline quantity for the trade package, which tenderers can be compared against.

2. Once broken in to components, a CA can compare pricing for separate assembled components as compared to the whole. For example, considering a paving package – the Head Contractor may determine whether to procure pavers separately and pay install costs only, or place supply and install onus on to one Subcontractor

3. The same analysis may be performed for tools, equipment hire and petty items. A chart of hire costs over time may be compared against purchase costs, to establish a favourable selection.

4.

In line with the requirements of the Head Contract, the builder is restricted to certain Subcontract conditions which lead to favourable outcomes for the Head Contractor and the client, as well as successful completion of the works.

The critical determining factors in contract selection are as below:

- Hire or Buy analysis to be considered with all procurement decisions. Particularly relevant to work packages involving bulk supply of materials, e.g., FRP. It may be more cost effective to procure concrete separately to concrete place. This would lead to the letting of a Construct Only contract – requiring no design input.

- Design Development requirements. With the standard design & construct Head Contract at Meadowbank TAFE, design documents are delivered to the contractor at 80% completion. Design continuation and coordination thus becomes the responsibility of the subcontractor; design must be completed to 100%/AFC, and then installed by the same Subcontractor. In this way, risks are minimised, and Subcontractors work to their own design.

- The same above goes for contracts requiring shop drawings etc., which must be coordinated and issued for approval.

- Where Subcontractors are only required to deliver completion of components as per drawings and are only on site for a short amount of time, they may be engaged on a Minor Works contract. This reduces commercial burden on the Subcontractor and ensures rapid onboarding.

When commencing Call for Tenders, the Contract’s Administrator must ensure responses are evaluated in accordance with Head Contract policies, as well as internal company policy. This ensures value for money, while mitigating legal risk and ensuring compliance with all relevant guidelines and statutory requirements. Where possible, pre-qualified suppliers/subcontractors are to be used. Prequalification indicates WHS requirements have been met, as well as commercial risks are mitigated.

Generally, evaluation at the first step consists of tender documents being returned signed and reviewed, indicating understanding and preparation for the next stage of evaluation. These documents consist of:

• Draft Subcontract (for review)

• Scope of Works

• Conditions of Tendering

• NSW Code Compliance Declaration

• Project Specific WHS Management Plan

• General Preliminaries

Along with the above, further non-price criteria evaluation can occur at the pre-award meeting. This is where expert judgement is used to compare Subcontractors to a range of metrics. A snapshot of these is presented below:

Code Compliance: Establish which code the project must adhere to, then ensure the Subcontractor meets compliance requirements.

Reference Check: Outline key references to be used in evaluating the Subcontractor and their past performance.

Resource Commitment: Ensure and discuss with the Subcontractor that necessary resources can be deployed as and when necessary.

Programme Confirmed: Discuss and present the project programme with the Subcontractor and ensure their ability to meet all dates and milestones

Primarily, the key consideration is pricing. Price comparisons will be performed using the following proforma, where comparison can be made between subcontractors, measured quantities and budget allowances:

Refer Section 5 – Contract Administration

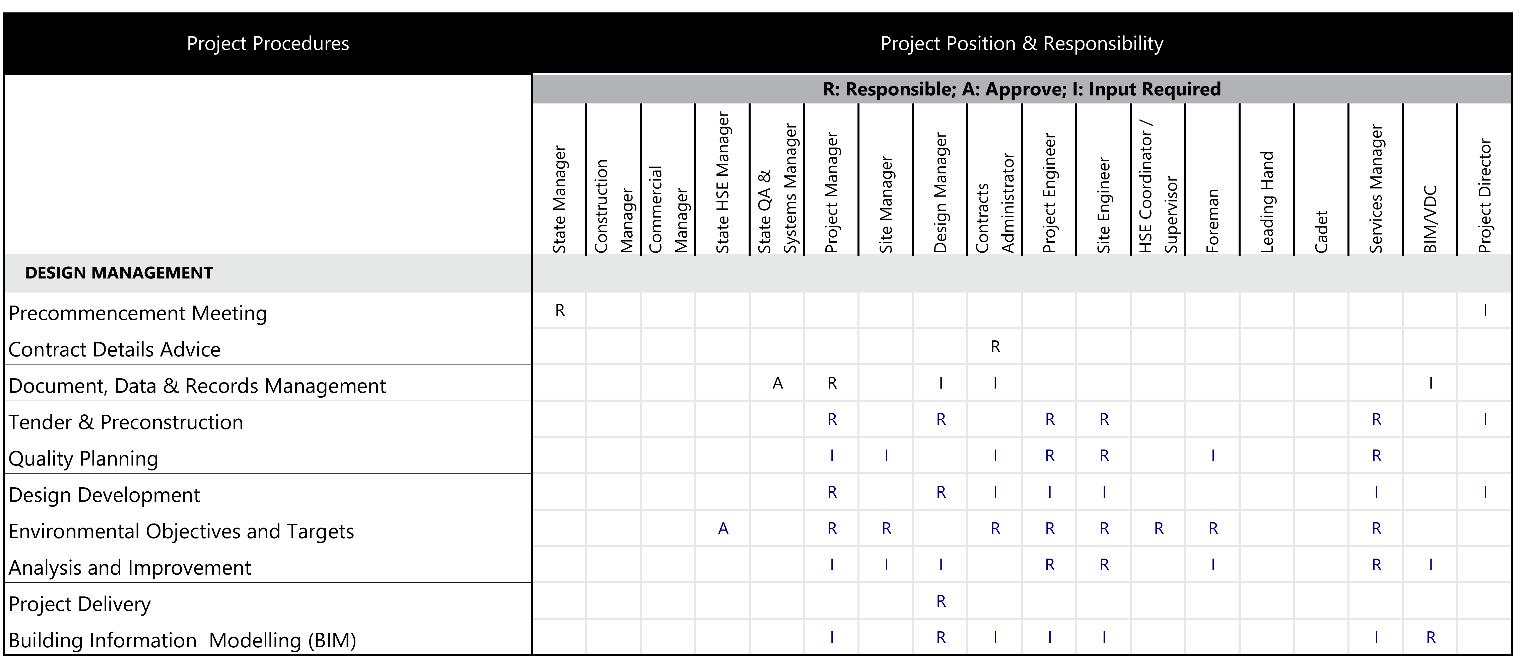

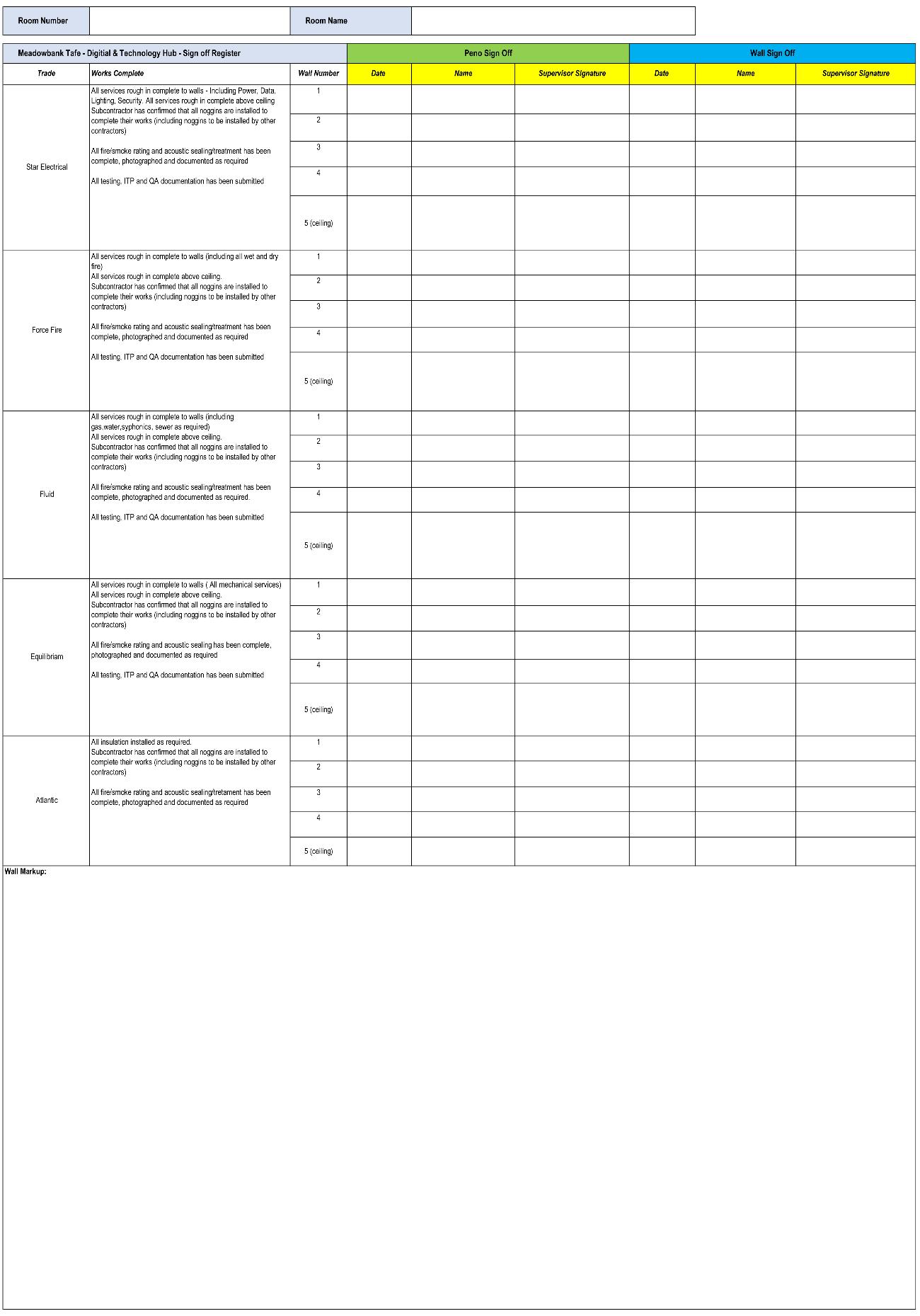

The purpose of the Quality Management Plan (QMP) is to detail the processes to be followed to identify essential building components throughout the construction delivery process; conduct inspections, monitor and test to verify specified requirements and inspect and test records to demonstrate compliance.

The QMP will be applied to:

▪ Ensure works are inspected and tested in accordance with requirements to provide evidence of compliance

▪ Ensure works are verified as complying and ‘approved’

▪ Ensure non-complying works are not ‘built in’

▪ Ensure auditing of quality performance is undertaken on all sites

As the Meadowbank TAFE project is NSW Government funded it will need to not only comply with the general conditions of the contract but also the NSW Government Quality Management Systems Guidelines for Construction.

In line with this, a project QMP has been developed which details and highlights the following:

• The contractual obligations in relation to quality with which we (the head contracted builder) have agreed to deliver

• The Project Objectives & Targets

• The Quality Assurance Process

• Quality Checklists (ITPs, etc )

• The Quality Control Process

• ISO Certification for Quality Integrated Management Systems

The Project Quality Management Plan covers the relevant elements of our Quality Management System and includes an index of our quality procedures and proposed Inspection and Test Plans (ITP’s) and associated checklists. Our ITP’s have incorporated Hold and Witness Points (contractually specified milestones in which no further work can proceed without approval).

Certification will be submitted which confirms that the QMP and Inspection and Test Plans of subcontractors and consultants meet the requirements of the contract guidelines. Work will not commence before the relevant documentation is submitted.

The contractor’s monthly report (PCG) which includes updates on quality issues will be submitted at the first site meeting in each calendar month. Each party must promptly notify (Early Warning) one another of anything that is likely to affect the quality of the project.

1.Project compliance with contractual and regulatory requirements

2. Maintain and enhance client satisfaction during construction and achieve total satisfaction on completion

1.1 QC/QA processes are established for the project, implemented, and maintained

2.1 During construction, obtain client feedback on builder’s performance at client meetings

2.2 Review client feedback and, if necessary, make changes to improve client satisfaction

Project Engineer

Project Manager

Site Engineers

Monthly during construction period

1.1.1 Verification of compliance to the QMP by internal audits

3. Ensure final product meets all requirements

3.1 Conduct inspections to ensure conformity of the project to head contract documentation

3.2 Ensure nonconforming works are identified and corrective/preventive action completed.

Project Manager

Construction period

Project Manager At PC and end of DLP

2.1.1 Maintain positive client satisfaction during construction period

2.2.1 Client Survey at completion

Site Engineers

Subcontractors

3.1.1 Complete all QC inspections

Construction period

3.2.1 Issues raised by the builder are all closed out

Quality Assurance is the IMS discipline of the day-to-day management of the project, to ensure quality outcomes are met throughout the project’s lifecycle. This differs from QC below, which involves validating and verifying project deliverables (the output) once they reach completion. From the perspective of the Contractor, there are several steps in establishing a project Quality Assurance process for the Meadowbank TAFE project:

Firstly, having established an understanding of the purpose and goals of the QMP, the detailed quality requirements related to project delivery must be determined. These include:

• Requirements specified by the client, including the requirements for delivery and post-delivery activities of the Meadowbank TAFE

• Requirements not stated by the client but necessary for specified or intended use, where known

• Statutory and regulatory requirements applicable to the project

• Any additional requirements considered necessary by the builder

The next step is establishing methods for client communication regarding quality. In general, the main communication method to the client is by regular PCG meetings in relation to:

• Project information and reporting

• Enquiries, contract or order handling, including amendments

• Program and project status

• Client feedback, including client issues/complaints

Having established requirements and communication methods, fulfillment of these requirements and ensuring satisfaction consistently, forms the Quality Assurance process. Information will be monitored constantly as to whether these requirements are being achieved by the implementation of the following control methods:

• Inspection / Test Plans

• Document Control System

• Sample Verification System

• Consultant Compliance Inspections

• Request to Inspect

• QC Checklist Monitoring System

• Subcontractor Monitoring

• Non-Conformance Management

• General Defects Management

• O&M, Handover and Training

Details of some key systems / quality assurance processes, are as follows:

Project QA records are stored electronically in the cloud. Generally, all project QA records will be contained within the BIM360 management system or contained in checklists within the system.

Further to the above, when considering project documents outside of QA, the site project team will review documentation “Issued For Construction” by the design team for any deficiencies or faults and notify the relevant stakeholders

Design queries will be submitted as a “Request for Information” via Aconex. A register of ‘RFIs’ will be maintained in Aconex and be updated as responses are received, and issues resolved.

Considering document ownership, client property includes all client requirements related to the project, namely:

▪ Building works paid for by the client

▪ Any intellectual property

▪ Drawings and specifications returnable to the client

▪ Samples, materials and products provided

Critical to the construction process is the continual review and approval of work packages. Without 3rd party review, a building element may not be able to be signed off, meaning traceability has been lost and an OC is unlikely to be issued. Therefore, consultants must be engaged to check compliance where necessary throughout construction. Examples of below consultants, the inspections they complete, and requirement timelines are given:

Consultant Site Inspection Register

Consultant

Architect

Structural Engineer

BCA Consultant

DDA Consultant

Acoustic Consultant

PCA

Inspection

Inspect for compliance with plans, design intent and specifications.

Before any element is closed (reinforcement, structural steel), to ensure verification of compliance to documents, as well as throughout the project lifecycle generally.

Inspects all building elements to ensure compliance with the BCA – e.g., Fire Rating, Exit paths, substation, accessibility, installation procedure

Ensures compliance with DDA standards (e.g., AS1428).

Db checks on rooms throughout to ensure acoustic specification has met

Regular checks throughout construction verifying compliance to all necessary standards, to issue OC.

Requirement

At regular intervals throughout construction.

Weekly/daily during structure, then less frequently.

At critical phases – e.g., at completion of structure; before wall closing; and for achieving OC.

When installation of critical DDA components has been completed.

At completion, prior to OC.

Throughout construction.

To ensure samples of products to be installed are agreed upon by the client, as well as all relevant stakeholders - including the builder, architect, and relevant consultants - a process is to be put in place to enable verification of samples by these parties. The flowchart of this process is as follows:

Subcontractor is requested to provide samples of items to be installed, either as per specification or deviating from spec.

The builder will review these samples, and if deemed acceptable will submit them to consultants - e.g., architect, acoustic consultant, BCA consultantfor review.

Once reviewed, the sample will go to the client for final sign off, with records of all previous reviews and any comments to be submitted to the client to facilitate their review, acknowledging their position as a nonspecialist.

As a natural part of the construction cycle, defects in work completed will be present. Defects are managed in 2 ways on this project: initially, the builder will hold subcontractors responsible for their works, expecting completion to standards as defined in contract scope and project documents. Above this process, however, an external defects process occurs with the client. The client, on site walks and inspections, is free to raise defects, to which the builder is responsible for closing out. Defects may be raised before or after handover, however they represent the assurance process that ensures the client receives the final product - the building - as desired and designed.

Fig. 28: An example of defect management in BIM360, using pushpins to show locations

A master ITP has been developed for the project, by the project team in consultation with all QA guidance above. This document will identify all:

- Necessary Inspections

- QA Record Submissions, and

- Hold Points

as they relate to Work Packages and respective specific work activities.