BLDG3022: CASE-BASED PROJECT

SYDNEY FOOTBALL STADIUM

REDEVELOPMENT

GROUP 13

DANIEL DAOUD z5309284

ALISIA HANNA z5312166

RAYNARD SUSANTO z5285167

CINDY YUAN z5271726

CHUOYU ZOU z5314107

8.5

1.1. PROJECT OVERVIEW

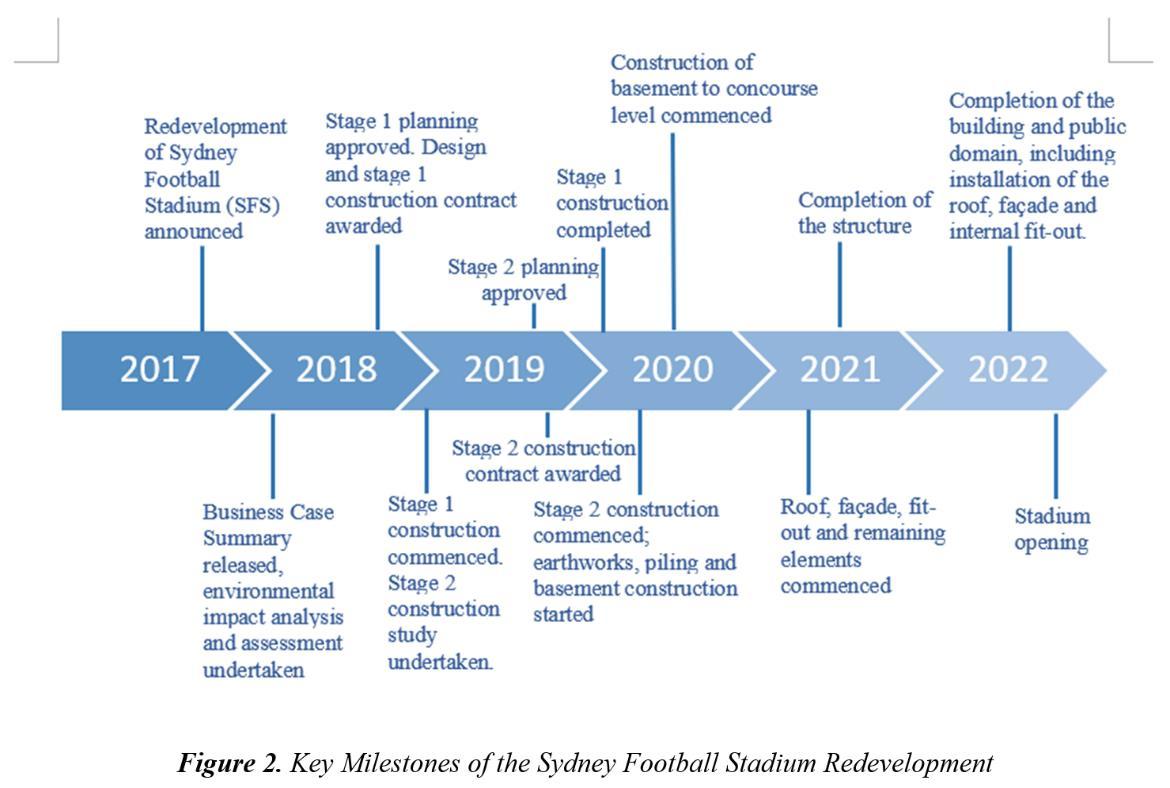

A Construction Project Management Plan (CPMP) is a document that includes information on the strategies, tools, resources, and knowledge sharing required to complete a construction project. Project managers may use this plan to determine the feasibility of the project viability and create resource schedules that are aligned with the project scope. Situated at Moore Park, which is adjacent to the Sydney Cricket Ground, New South Wales is the Sydney Football Stadium (SFS). This project is a redevelopment of the Allianz Stadium into a modern world-class venue for sporting and entertainment purposes. This project has an estimated total cost of $828 million and will include features such as a full roof coverage of over 45,000 seats, an open domain for easy mobility for the public, increased cafeterias, and advanced amenities. The SFS Redevelopment has announced in November 2017 that the project will commence in early 2020 and is expected to complete in July 2022.

This CPMP has been prepared by Group 13 Project Management Team for the purpose of supporting the planning, execution, management, and closure stages of the Sydney Football Stadium (SFS) Redevelopment Project. The CPMP will include the following items:

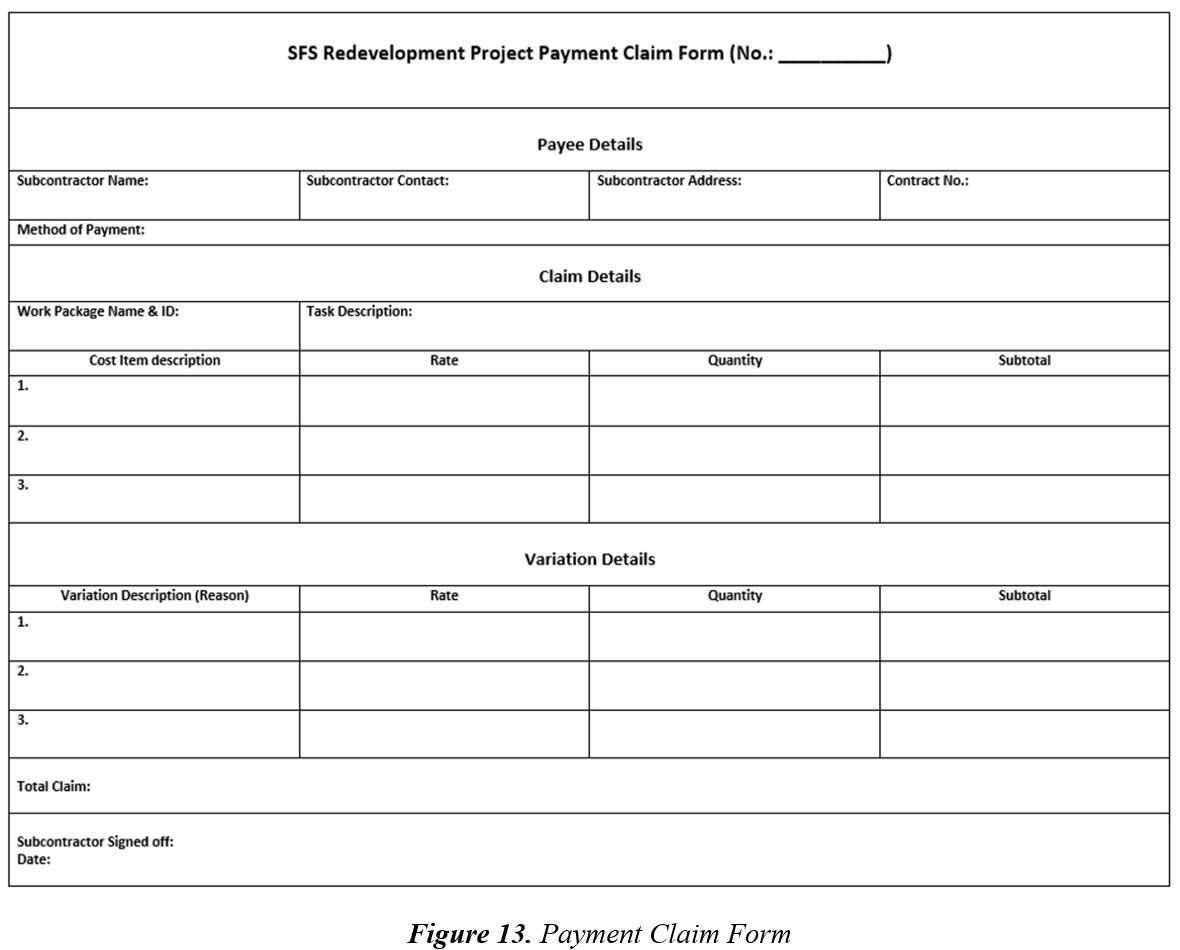

➢ Project Charter

➢ Scope Management Plan

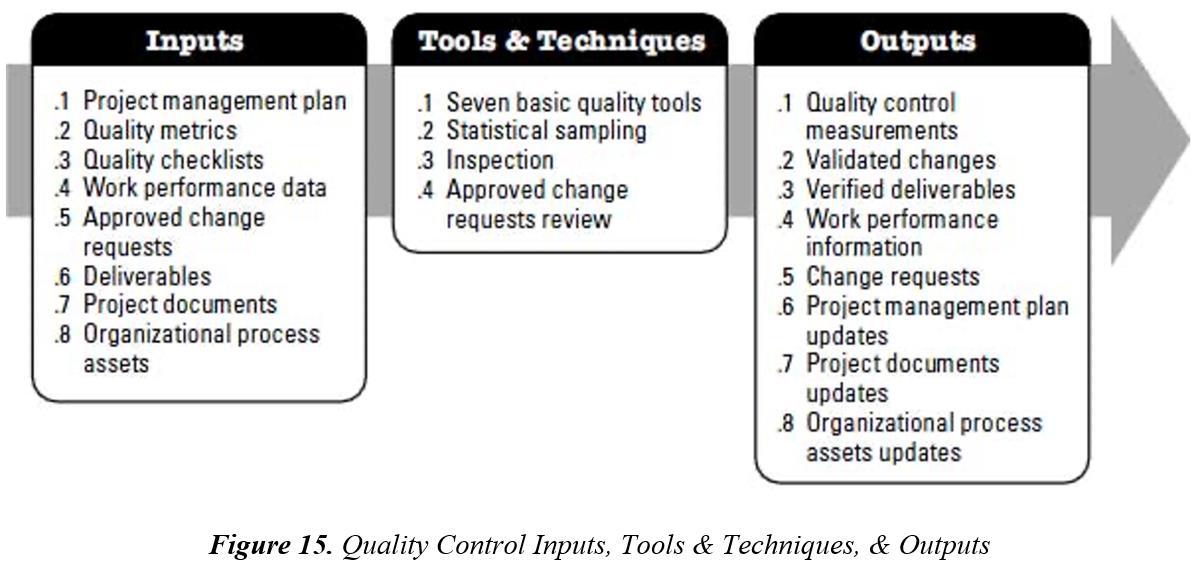

➢ Schedule Management Plan

➢ Cost Management Plan

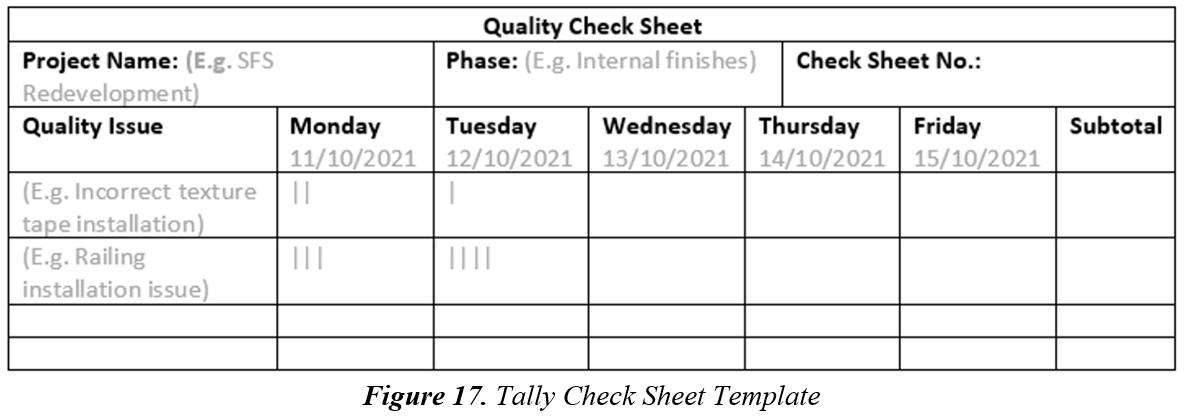

➢ Resource Management Plan

➢ Procurement Management Plan

➢ Quality Management Plan

➢ Risk Management Plan

➢ Stakeholder Management Plan

➢ Communication Management Plan

➢ Health, Safety, Security and Environmental Management Plan

The Project Manager (PM) can be held accountable and ensure that employees are committed to delivering the project on time while achieving excellent quality with the help of the CPMP. In addition, this plan will serve as a communication tool between key stakeholders, and the PM will update the plan as required during the project life cycle. Any change requests will need approval from project sponsors and before implementation, and documented in this plan.

PROJECT SCOPE MANAGEMENT PLAN & SCOPE BASELINE

2.1. PROJECT SCOPE DEFINITION

The Sydney football stadium is an advanced world class venue that provides the city of Sydney with a sporting and entertainment venue. The stadium has been designed by COX architecture and serves a purpose in allowing an enhancement in the local area by providing new active spaces.

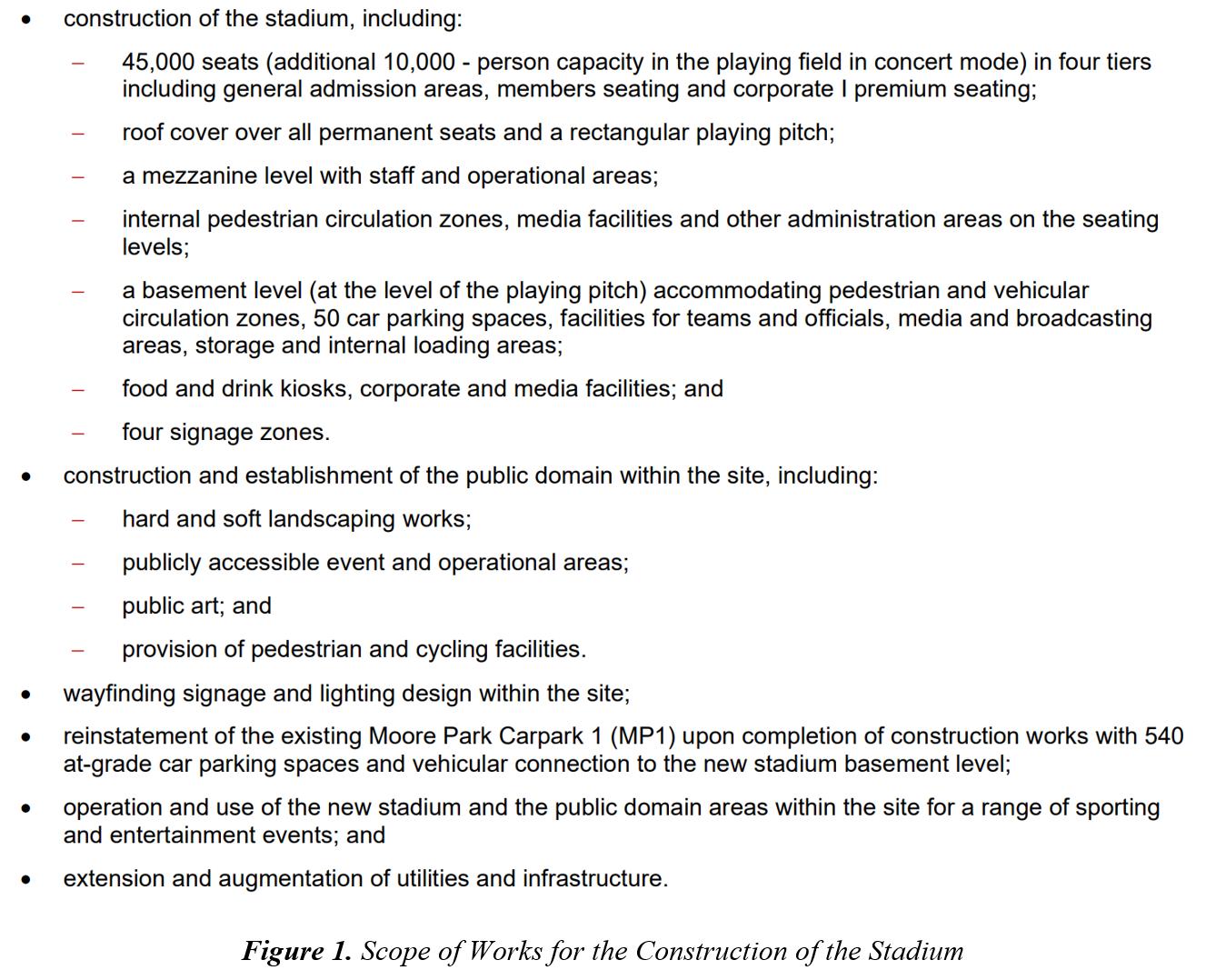

The scope of works includes:

2.2. PROJECT SCOPE STATEMENT (PSS)

Project Name: Sydney Football Stadium Redevelopment

Client: NSW Government

Project Description

Date: 21st September 2021

John Holland is pointed as the main contractor to redevelop Sydney Football Stadium into a world class venue in the city of Sydney. The Sydney Football Stadium is redeveloped to satisfy people in NSW as the number one choice for sport competition and entertainment purpose. The redevelopment announcement was started in 2017 and expected to be completed in 2022. This redeveloped stadium will welcome athletes and sporting fans in a big competition including 2023 FIFA Women’s World Cup and 2032 Summer Olympics becoming a new icon of Sydney.

Project Deliverables

The Sydney Football Stadium redevelopment will include a new stadium with sustainable design, constructionandoperation,entertainmentservicesandsportingeventtostimulatetheeconomyinSydney

Stadium

An infrastructure project able to stimulate economic growth and provide job opportunities, and become a national and international hub for entertainment.

Sustainable Design, Construction and Operation

It is key that the stadium be built to sustainable design. This involves ensuring all aspects be taken into consideration:

➢ Energy requirements

➢ Dust

➢ Noise pollution

➢ Vibration

➢ Road and travel services

Entertainment Services

The stadium will be able to enhance the game day experience and atmosphere through providing a redeveloped and improved design.

Economic stimulation

The stadium will be able to provide the local economy with an increase in persons within the area and hence persons able to purchase goods and services therefore stimulating the local economy.

Project Acceptance Criteria

The Sydney Football Stadium will ensure that the scope of work is in compliance with:

➢ Sydney Football Stadium Redevelopment Contractual Project Requirements

➢ Sydney Football Stadium Redevelopment Mechanical Specification

➢ Sydney Football Stadium Redevelopment Civil Specification

➢ Sydney Football Stadium Redevelopment Design Drawings

➢ Sydney Football Stadium Redevelopment BASIX Report and Specifications

➢ All defects in the defect liability period will be fixed to ensure the safety and wellbeing of the community

Project Exclusions

The key activities and products excluded from the scope of work are:

➢ Demolishing the existing stadium that was happened in 2019 was done by Lendlease

➢ Development of car parks and motorcycles spaces

Project Constraints

The project constraints are as follows:

➢ Coronavirus: Due to COVID-19 pandemic construction has been slowed down drastically due to either supply issues or government stay at home orders. This has a constraint on the amount of time the project needs to be completed due to government orders.

➢ Vaccination: All members in the construction industry are required to be double dose vaccinated against coronavirus, for this reason workers have to take time off work and hence limits the schedule.

➢ Money: The Australian government has allocated a $828 million budget. This is a set financial resource allocation done by the NSW government.

➢ Time: Construction projects often take longer to complete than initially thought, for this reason the planning stage is the most critical to ensure key milestones are met to ensure the schedule is being met.

➢ Stakeholders: Noise pollution due to machinery and construction works has an effect on the nearby stakeholders so there is pushback from stakeholders on the stadium being created.

➢ Resources: There is currently a shortage of timber in NSW along with resources being preordered to ensure the efficiency on site when building.

➢ Quality: The works must be compliant with all Australian regulations and must be completed to a high standard to ensure that client needs are satisfied.

➢ Work Health and Safety: All works must comply with WHS act 2011 and WHS regulation 2017, this compliant to safety may affect time and cost constraints as special needs may be needed.

➢ Weather: A rainy day will always affect the project to be delayed because no workers are able to work during rainy days. During the rainy season, the construction progress will slow down a bit

➢ Noise, vibration, and dust: Construction projects always create noise, vibration, and dust to the environment. To minimise, all works must comply with Australian Standards 2436 and WHS Regulation 2017.

Project Assumptions

The project assumptions are listed below:

➢ The project cost will not succeed the set $828 million

➢ Project planning schedules will be met

➢ All stakeholders understand their roles and responsibilities

➢ The project will not include any other variations

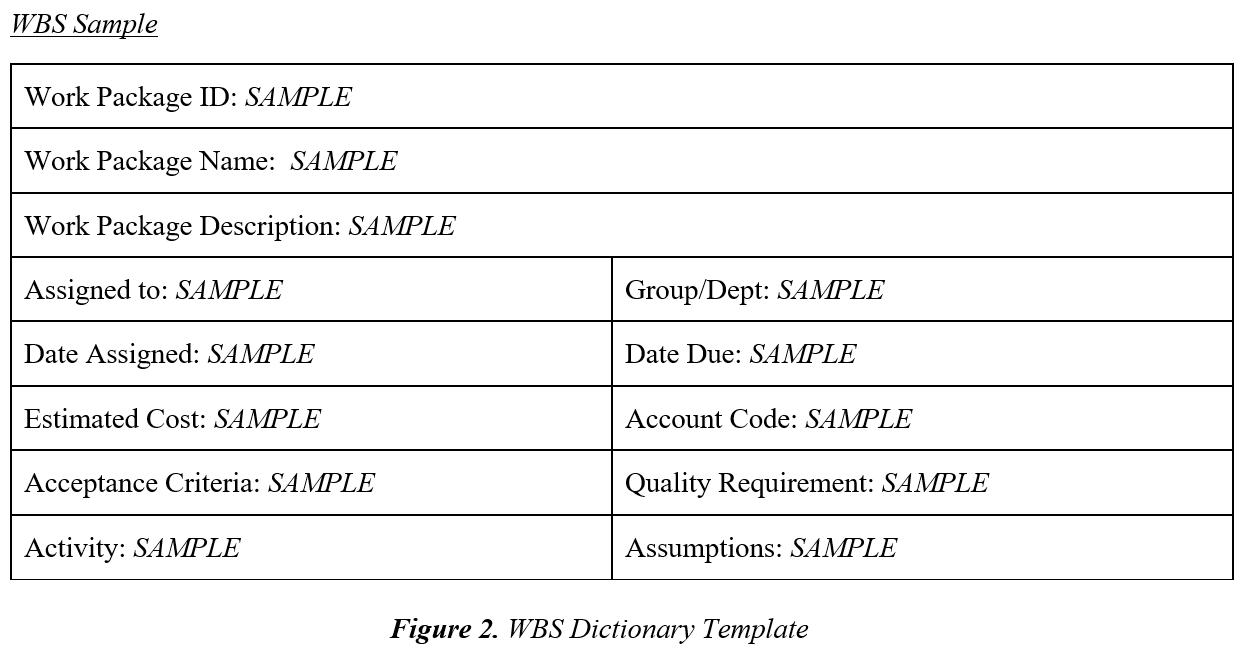

2.3. WORK BREAKDOWN STRUCTURE (WBS UP TO LEVEL 3)

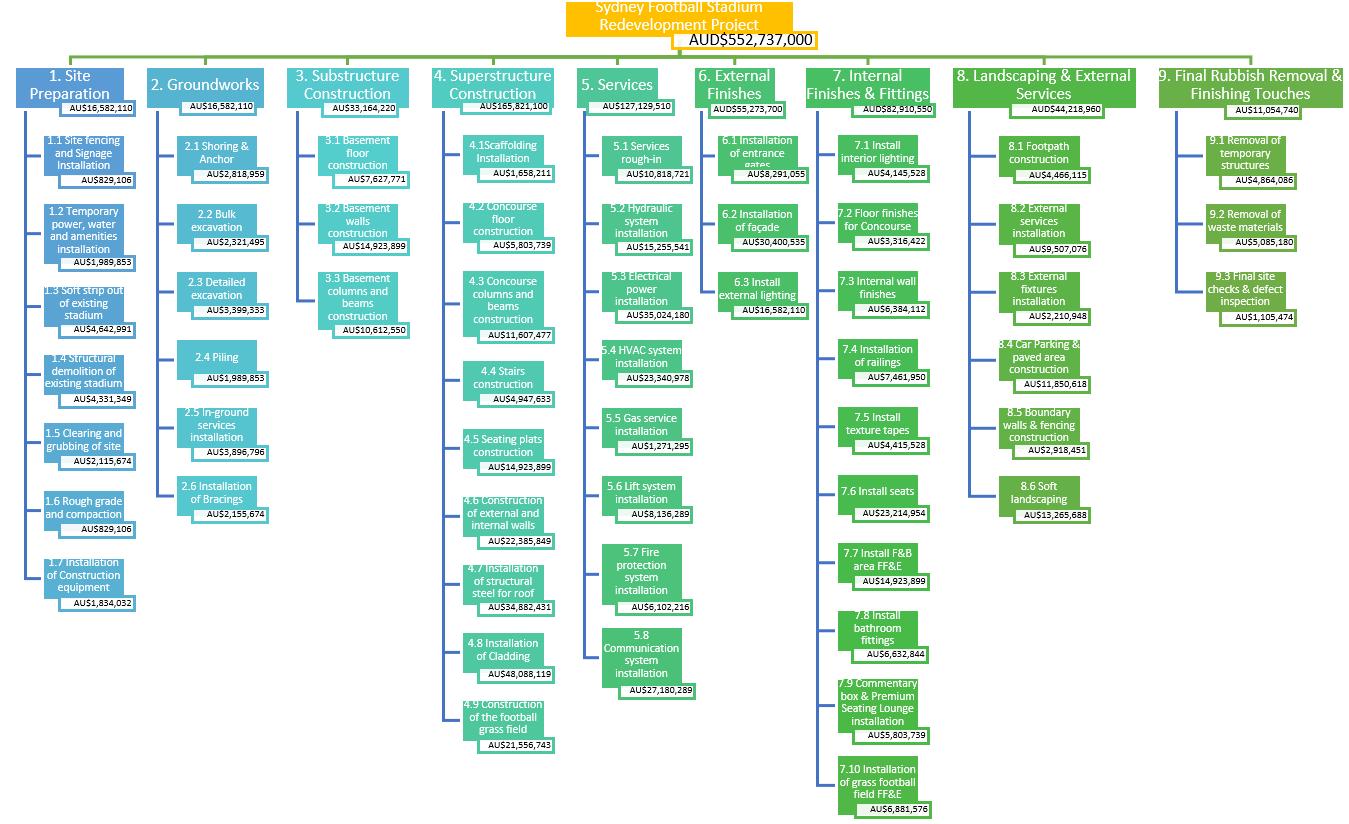

2.4. WBS DICTIONARY (SAMPLE & 3 DICTIONARIES)

The WBS dictionary template adopted by this project is shown in Figure 2 below. WBS dictionaries willbepreparedforallworkpackagesinvolvedinthe WBSshowninsection2.3.ThreeWBSdictionary samples are provided below demonstrating the requirements and level detail for each work package in this project.

WBS Dictionary Sample for Demolition:

Work Package ID: 1.1

Work Package Name: Demolition

Work Package Description: this work package involves disconnection of services from the stadium, as well as soft strip out demolition and structural demolition of the existing stadium.

Assigned to: Angus Morten

Date Assigned: 1st Jan 2019

Estimated Cost: $40 million

Acceptance Criteria:

➢ The outcome meets the quality requirement.

➢ Final inspectioniscompletedbythe site engineer and site director.

Activity:

Group/Dept: Lendlease demolition project team

Date Due: 15th September 2021

Account Code: 055_Dem

Quality Requirement:

➢ Localcommunityisnotifiedandregularlyupdated with the demolition progress and upcoming events.

➢ Adhere to Australian Standard AS 2601-2001: Demolition of Structures

➢ Adhere to Safe Work Method Statement (SWMS) specifications

Assumptions:

➢ Disconnection of services

➢ Soft strip out of ancillary building

➢ Soft strip out of seats and F&B service areas

➢ Lowering the roof

➢ Structural demolition of existing stadium

➢ Processing and removal of waste stadium materials

➢ Plants removal

➢ All necessary approvals for demolition work to commence are acquired.

➢ Site investigation and site establishment are completed

➢ Service diversion and isolation from the stadium are completed before demolition commence

➢ Relocation of pedestrian and traffic is completed before demolition commence.

➢ Processing and removal of stadium materials are as per waste management plan

➢ Noise, vibration and dust management are as per project management plan

WBS Dictionary Sample for Basement Slab Construction:

Work Package ID: 2.3

Work Package Name: Slab on ground

Work Package Description: This work package involves construction of the concrete slab for basement of the stadium

Assigned to: Paul Cassel

Date Assigned: 5th Aug 2020

Estimated Cost: $900,000

Acceptance Criteria:

➢ The outcome meets the quality requirement.

➢ Quality test completed, final inspection is completed by site engineer and site director.

Activity:

➢ Material delivery

➢ Lay vapour barrier

➢ Lay reinforced steel

➢ Concrete pouring, screeding, floating and curing.

➢ Apply finish on top of the slab

Group/Dept: John Holland construction team

Date Due: 30th Aug 2020

Account Code: 073_BCS

Quality Requirement:

➢ Local community is notified and regularly updated with the construction progress.

➢ Adhere to Australian Standards requirement.

➢ Adhere to Building Code of Australia (BCA) requirements

➢ Adhere to Safe Work Method Statement (SWMS) specifications

Assumptions:

➢ All excavation works are completed

➢ Preparation of solid, levelled ground for concrete pouring is completed

➢ Traffic control as per traffic control management plan

➢ Material delivery as per resource management plan

WBS Dictionary Sample for Roof Construction:

Work Package ID: 3.4

Work Package Name: Roof construction

Work Package Description: This work package involves installation of roof’s steel structure, polycarbonate cover and facade

Assigned to: Paul Cassel

Date Assigned: 10th May 2021

Estimated Cost: $100 million

Acceptance Criteria:

➢ The outcome meets the quality requirement.

➢ Quality test conducted, final inspection is completed by site engineer and site director.

Activity:

➢ Material delivery

➢ Install structural roof steel

➢ Installation of polycarbonate roof and façade

Group/Dept: John Holland construction team

Date Due: Late 2022

Account Code: 087_ROF

Quality Requirement:

➢ Local community is notified and regularly updated with the construction progress.

➢ Adhere to Australian Standards requirements

➢ Adhere to Building Code of Australia (BCA) requirements

➢ Adhere to Safe Work Method Statement (SWMS) specifications

Assumptions:

➢ Noise control is conducted to ensure the noise is within predicted allowable levels.

2.5. SCOPE VALIDATION & VERIFICATION PROCESS

The delivery team will engage with key stakeholders to ensure that the work packages and deliverables conform with the original project scope. These stakeholders include the clients, architect, engineers (hydraulic, structural, mechanical, communication, electric and fire) and other consultants. The team will conduct inspections by measuring, examining and validating completed deliverables and comparing them to specified requirements to ensure that they are satisfactory to the client. Regular site inspections are conducted at key milestones as the project progresses.

Inspections are also undertaken at the end of each work package (indicated in Section 2.3) by consultants assigned by the client to verify the works. After the inspection, the team will meet with the project sponsors for formal acceptance and create accepted deliverables which will then be forwarded to Close Project Phase. Project documents such as lesson learned register, requirement documents and traceability matrix will be updated. It is also the delivery team’s responsibility to ensure that the sign off sheet and other formal documents are recorded for future references.

Completed deliverables that have not been formally accepted will be reported, change requests will be issued for defect repairs and corrective measures. This process is repeated until client satisfaction is achieved.

The flowchart shown below describes the process of scope verification:

2.6. SCOPE CONTROL PROCESS

Project Monitoring & Control System:

Clear communication is essential to track the project's scope throughout its many construction disciplines, coordinating any modifications and/or ensuring that drawing requirements are recorded in each discipline's scope of work. The goal is to avoid situations when scopes do not capture all of the needed deliverables, resulting in changes to the project budget assigned to that discipline.

Scope Status Management:

Project contract administrators should have payment progress breakdowns set up monthly through the progress claim procedure in order to monitor cost against deliverables supplied and their % completion. This will necessitate the submission of trade break ups in order to maintain track of the scope agreed upon, as well as analysis when scope statuses need to be confirmed against cost. To monitor expected scope activities that have not been performed, relevant design managers and/or engineers must analyse the progress claims against the scope.

Scope Compilation Process:

1. Conducting effective tender meetings with the relevant building discipline to go through drawings, specifications, and details as part of the scope of work. Engineers will examine the appropriate paperwork to identify critical deliverables that must be included in the scope of

work. During tender discussions with possible tenderers for trade/consultant packages, engineers are encouraged to work with contract administrators and project managers.

2. Review scopes from prior comparable projects and talk through lessons learned from scope management items.

3. It is necessary to ensure that the scope of the head contract (e.g., GC21 NSW Government Projects) has been reviewed and that conditions such as post-construction maintenance, handover documentation (e.g., O&M manuals, As-Built drawings), training (i.e. providing training on howto use the new system), and relevant certifications for the occupation certificate have been included. It's possible that failing to include these elements in the scope may result in an inability to fulfil handover deadlines and additional costs.

4. Facilitate appropriate scope review workshops to go through the scope and identify any areas that were overlooked or that needed further information.

5. Once the scope has been agreed upon, ensure that a written statement from each party has been provided via Aconex and that a copy ofthecommunication has been saved onthe project server under the contract's administration area.

6. The subcontractor must understand and agree on tentative sums.

7. Site instruction correspondence for any customer variations is to be provided to the subcontractor for a charge that will be repaid to the client's head.

2.7. SCOPE CHANGE MANAGEMENT PROCESS

Project scope changes are the addition, subtraction or modification of the project scope. Scope changes are usually unavoidable in the projects, and can occur for a variety of reasons, including but not limited to:

➢ When additional project needs are identified, such as a change in client preferences or a modification to the project design, the client, project sponsor, contractors, or other project stakeholders may establish a scope change request.

➢ Common construction issues, such as funding, materials supply, and labour.

➢ Change of project constraints, such as environmental constraints, social constraints, new government legislations or regulations.

When scope changes cannot be managed properly, scope creeps may occur and cause an increase in project risks, project delays, budget overruns, or even quality issues. To effectively manage the scope changes, a scope change management process is developed for the Sydney Football Stadium project, outlining how the scope changes will be initiated, processed, decided and controlled over the project life cycle. All the scope changes to the Sydney Football Stadium project need to be processed under the change request procedure, as shown in the flowchart below:

Step 1: Establish Change Request (CR)

To request a project scope change, the SFS redevelopment project team members or stakeholders need to first complete and submit a change request (CR) form to the change manager (sample change request form provided below). The change manager needs to enter the CR into the system (CR Log), provide primary justification to the CR, and update the CR’s status throughout the CR process as needed.

Change Request Form

Project Name: Sydney Football Stadium Redevelopment Project

Submitter: Date of request:

Department / location: Contact [Phone/Email]:

CR No.: Title: Priority:

Description of the change:

Impact of the change:

Proposed action:

Status:

Step 2: Project departments review Change Request

As CR is entered into the system, project departments that the proposed CR has a potential impact on are responsible to review the CR, analyse the impact of the change and develop solutions for the potential impacts. This information will be recorded in the change request form and submitted to the project manager.

Step 3: Change Request evaluated by the project manager

As the change request form is submitted to the project manager, the project manager needs to evaluate the change request form. The project manager may approve or deny the CR depending on the feasibility of the CR; if the project manager approves the proposed CR, a Change Control Board (CCB) meeting will be scheduled to make a final decision on the CR.

Step 4: Authorise change request

The CR approved by the project manager will be submitted to the Change Control Board (CCB) of Sydney Football Stadium Project. The CCB consists of a minimum of 7 senior members of the Sydney Football Stadium redevelopment project board of directors, and is responsible for meeting, reviewing

the change request and making the final decision to approve or reject the CR. Details of the CCR is provided in the table below:

Role Name Contact Description/Responsibility

Project Manager

[Name] [Email/Phone]

Client (SFS) Representatives

Local Community Representatives

Peter Hynd (SFS Project Director, Infrastructure NSW)

Oversee and approve project scope changes, organise CCB meetings. Communicate the approved CR to relevant departments and stakeholders. Supervise change implementation process.

[Email/Phone] The authority to approve or deny the CR. Responsible for ensuring that scope changes are in line with the project's scope and mission. Assess the CR's feasibility in terms of project funding.

Julie Osborne [Email/Phone] Monitor the impact of the CR on the local community, communicate the concerns that arises within the local community to the CCB and assist in resolving disputes. Ensuring the negative impact of the project on the local community is kept to a minimum.

Local Government Representatives Cr Philip Thalis (City of Sydney Council)

Head Contractor Angus Morten (Lendlease)

Paul Cassel (John Holland)

Impacted Project Department Representatives

Change Manager

[Email/Phone] Ensure the CR are compliant with local government’s regulations and construction development guidelines, in order to minimise the negative impact of the project on the local community.

[Email/Phone] Assess the feasibility of the CR, ensure subcontractors and staff are aware of the changes and undertake construction works in accordance with the approved CR.

[Name] [Email/Phone] Assess the feasibility of the proposed CR, analyse the potential impacts of scope changes. Implement approved changes and report the result of scope change to the project manager and CCB and suggest solutions.

[Name] [Email/Phone] Make primary justification to the CR and update CR status in the system. Enforce and oversee scope change implementation process, update project documentation.

Step 5: Implementation of change request

OncetheCCBhasapprovedtheCR,theprojectmanager isresponsibleforcommunicatingtheapproved scope changes to the project team. Projects documentations that are affected by the changes also need to be updated, such as:

Constructionmanagement plan: scope management plan, schedule management plan, cost management plan, resource management plan, etc.

➢ Project drawings

➢ Contacts

➢ Other project specifications

Step 6: Tracking Change Implementation Progress

Regular review of the change implementation progress for Sydney Football Stadium project will be completed by the change manager to determine the effectiveness of the scope change. Any necessary modifications of the change request will be reported to the project manager and CCB, and will be assessed by relevant project departments.

PROJECT SCHEDULE MANAGEMENT PLAN & SCHEDULE BASELINE

3.1. SCHEDULING METHODOLOGY & TOOLS

It's critical to establish a pre-project planning framework for big projects like the Sydney Football Stadium. Another key feature of this pre-project planning outline is that it must be led by the managing contractor in accordance with the head contract and all milestone dates. It will be necessary to include clearly defined roles and responsibilities, as well as users such as operations and maintenance, in the outline.

An example of a procedure that can be utilised is:

➢ Plan schedule management

➢ Define activities

➢ Sequence activities

➢ Estimate activity resources

➢ Estimate activity durations

➢ Develop schedule

➢ Control schedule

3.2. ACIVITY IDENTIFICATION & ESTIMATE DURATION METHODS

3.2.1 – ACTIVITY

IDENTIFICATION

The activity identification is the process of determining activities involved in the Sydney Football Stadium Redevelopment. It is a critical step in schedule planning and development which includes estimating durations, identifying and defining resources, and determining external project constraints. The tools and techniques that will be applied are given below:

1. Decomposition

This technique progressively divides and subdivides deliverables into smaller components where the top layer (WBS) encompasses the decomposition and each layer gives a further breakdown and definition of the previous layer. The project team is to decompose the entire scope of works in order to achieve the project objectives and produce the requisite deliverables.

With project decomposition, work packages of the Redevelopment will be clearly identified which enables the project team to:

➢ Increase the accuracy of time and cost estimates

➢ Determine the scope

➢ Identify and control risks

➢ Have better control over the execution of the Redevelopment

➢ Develop a more precise plan

2. Rolling Wave Planning

This is the process of project planning where work packages become more detailed as they get closer to being current activities when the project proceeds. The project team will progressively elaborate and refine the work packages in greater detail over time.

3. Expert Judgement

Expert judgement is a vital technique for planning the project schedule of the Sydney Football Stadium as limited expertise can have a negative impact on delivering the project on time and with quality. It is based on the team's past experiences, skills, specialized knowledge, and expertise. The Project team

will seek judgments from experts including engineers (civil, structural, electrical, hydraulic and mechanical), project managers, project sponsors and consultants to identify activities.

4. Historical Information

The project team will collect and analyse data and lessons learned of historical projects similar to the Football Stadium in order to have a better understanding of how to determine the activities and avoid unnecessary mistakes. In the Sydney Football Stadium Redevelopment, the project manager and the team will examine and analyse data of the Western Sydney Stadium to define activities, make estimations and effectively improve the construction plan.

3.2.2 – ACTIVITY DUARTION ESTIMATING

Expert Judgment (team’s past experience)

Expert Judgement represents a point of view by the amateurs based on his/her experience in the construction area. An expert might include someone in the project team with specialized skill, education, training, knowledge, or even experience. The expert judgement is suitable on the situation when validating, interpreting, and integrating a data, calculating the possibility of upcoming events and theopportunitiesorthreads.Thecommonapproachofexpert judgement isaninterviewwiththeexperts by asking them a list of statements/questions. The presence of opinions by the experts is part of evaluation when defects/faults happened, then their opinions act as solutions/recommendations of problems and to improve so that those defects would not happen again in the future.

Analogous Estimating (historical records)

The analogous estimating technique analyses data from similar projects to create a cost estimate based on the information given. The combination of expert judgement with this method will be required to achieve a ‘dictionary’ for future projects. When there is a lack of information regarding the project, analogous estimating is utilised. Assuming that broad parallels can be found with a past project, then estimates about the cost, effort, and other factors required to complete the current job may be made.

Parametric Estimating

The elements that have the greatest influence on the work required to complete a software project successfully are time restrictions and defect elimination quality. There are tools available to aid with the estimating technique, and it is critical that any tool used can generate a duration assessment with risk for the go-live date, taking into account the estimated number of faults, in addition to resources and personnel profile. Depending on how many problems are introduced and how near to a zero-defect application the aim is to achieve, the testing effort will grow correspondingly.

Three-point Estimating

Three-point estimating is a statistical approach that may be combined with bottom-up estimating to get useful results. The most likely result is calculated by combining the lowest and highest estimates. Another approach to utilize three point estimating is to take the result from parametric estimating and combineit with the accuracy oftheinput, suchasfunction points,togeneratea picture of the cost range. If the size estimate for a parametric estimate has a potential variance of 25%, scenarios may be built to show the relative costs at the greatest and lowest size values, providing other factors like time remain constant.

Group Decision-Making Techniques

The group decision making technique involves brainstorming with the team members to estimate/pick the best choice/idea to solve an issue. After that, rational ideas are collected to be discussed with the team members. Cause and effect of each idea should be taken into consideration. Using the fishbone diagram will help to illustrate a variety of causes that are possible to happen and interrelated with the

effect or problem. After that, voting would be ideal for the team members to choose the best alternative after analysing the cause and effect in different situations.

Published Estimating Data

The team can utilize acquired data to inform their estimations by utilizing published data from sources such as books and industry magazines. One of the trusted published data is Rawlinsons.

Simulation

Program Evaluation and Review Technique (PERT) is a way for determining a Critical Path Method (CPM) variation by examining the activities in a timetable. It determines the minimal time to accomplish a project by analysing the time necessary to perform each job and its related dependencies. It calculates the quickest possible time for each action, the most likely amount of time, and the longest potential time if the activity takes longer than predicted. There are 3 terms to be understood before conducting PERT analysis :

➢ Optimistic time (O) = the shortest amount of time necessary to complete a task, assuming everything goes as planned.

➢ Pessimistic time (P) = the greatest amount of time it will take to complete a task if everything goes wrong

➢ Most likely time (M) = the most accurate estimate of how long it will take to complete a task if everything goes according to plan.

The formula to estimate how much time required for each project could be calculated as follows:

(P+4M+O)/6

3.3. ACTIVITY SEQUENCING METHOD

Precedence Diagram Method (PDM) is adopted to demonstrate the sequences of construction activities for SFS Redevelopment project. The project activities are connected with arrows, as shown in the sample precedence diagram below. With the use of PDM, information such as relationships between the project activities, activity duration, start and finish dates, as well as lead time and lags can be displayed in a logical and efficient manner.

SFS project team will carefully examine the project activities to determine the best relationships, dependencies, lead time and lags for the project activities. This ensures that the project activities are planned in the most efficient and rational activity sequences possible.

3.3.1 – RELATIONSHIP TYPES

There are 4 main types of relationships among construction activities of the SFS Redevelopment project, which are the Finish to Start (FTS), Start to Start (STS), Finish to Finish (FTF), and Start to Finish (STF).

Type of Relationship

Description

Finish to Start (FTS) The succeeding activity cannot start until the preceding activity is fully completed. This is the most common activity relationship in SFS project.

Start to Start (STS) The succeeding activity cannot start until the preceding activity has commenced.

Finish to Finish (FTF)

The succeeding activity cannot be completed until the preceding activity has fully completed.

Start to Finish (STF) A lead time portion of the preceding activity must be completed so that a lead time portion of the succeeding activity can be completed.

Example

Softstripoutoftheroof(preceding activity) and installation of roof structural steel (succeeding activity)

Trenching (preceding activity) and laying pipes (succeeding activity)

Power to lights (preceding activity) and installation of lights (succeeding activity)

Electrical wiring (Preceding activity) and lift installation and testing (succeeding activity)

Notice that a compound of two or more types of relationships may exist between two construction activities, hence the start and finish dates of activities must be carefully determined to satisfy all the requirements.

3.3.2 – DEPENDENCIES DETERMINATION

Activity dependency is a logical, constraint-based or preferential order of the construction activities. When sequencing the construction activities of the SFS redevelopment project, 4 types of dependencies are considered:

➢ Mandatory dependencies (hard logic) - The term "mandatory dependence" refers to a working connection that is unavoidable. This indicates that because the duties are contractually necessary, no other work shall be completed until the requirements of the mandatory tasks are met.

➢ Discretionary dependencies - A discretionary dependency is one that is based on a ‘should’ rather than a ‘have to’. Discretionary dependencies, often known as soft logic, represent how project teams expect to finish tasks. The project team can use this form of dependence to optimize the flow of work throughout the project life cycle. Simply said, one group of actions mayoccur atthesametimeasanother.This dependenceisusedbyproject managerstogenerate a "float" on the timeline.

➢ Internal dependencies - Between two project tasks, internal dependencies are defined.

➢ External dependencies - An external dependency is a requirement for a task to begin that requires input from a third party. This reliance is manifested as an approval.

➢ Dependencies of activities are carefully chosen based on study of the relationships between the construction activities.

3.3.3 – LEAD TIME & LAG

Lead time and Lag are the acceleration or delay of succeeding activities. In some circumstances, lead time and Lags need to be introduced between two activities, to develop a more time-efficient activity schedule while maintaining a high-quality standard of construction works. When scheduling project

activities, SFS redevelopment project management team will determine whether each dependency requires a lead time or a lag in order for the activities to run smoothly.

3.4. PROJECT SCHEDULE BASELINE (UP TO LEVEL 3)

3.4.1

– LEVEL OF ACCURACY

ThelevelofaccuracyforSydneyFootball StadiumRedevelopmentisaround4percent ofthecompleted schedule.Theschedulebaselinewillbefurthercomparedwiththecompletedscheduleinordertodecide whether further steps are required to keep the project on track.

3.4.2

– PROJECT WORKING DAYS & CALENDAR

Sydney Football Stadium construction site operates from Monday to Saturday, including public holidays:

➢ Monday to Friday: 7am - 5pm

➢ Saturday: 7am - 6pm, most works expected to be completed by 3pm.

3.4.3 – MASTER SCHEDULE

3.5. PROJECT MILESTONES & TIMELINE

KEY Milestones Estimated Completion Timeframe

NSW government announced the redevelopment of Sydney Football Stadium (SFS)

Business Case Summary released and final estimated cost announced ($729 million).

Request for Secretary’s Environmental Assessment Requirements (SEARs) lodged with the Department of Planning and Environment

Community and stakeholder engagement commenced

Department of Planning & Environment (DP&E) prepared & issued SEARs for preparation of Environmental impact Statement (EIS).

Stage 1 DA publicly exhibited

Design competition released to four participating firms

Response to Submissions Report released

Stadium operations cease

ThewinningdesignforthefutureSydneyFootballStadiumwas released (submitted by Cox Architecture and Aspect Studios).

The stage 1 of the redevelopment of the Sydney Football Stadium was approved, which involved the demolition of the existing stadium and a concept proposal for a new stadium.

The NSW government announced that Lendlease would be the construction contractor, stage 1 construction contract (demolition of existing stadium) awarded to Lendlease.

Soft strip out demolition work commenced

Stage 2 request for SEARs lodged with the DPE

Commencement of structural demolition

Stage 2 SEARs issued by the DPE

Stage 2 DA for the detailed design, construction and operations lodged with DPE

Stage 2 EIS on public exhibition

Response to submission published on Department of Planning, IndustryandEnvironment’swebsite

Stage 2 tender shortlist announced, Multiplex and John Holland were invited to participate in the tender process to deliver stage 2 of the project (reconstruction of the stadium)

Stage 2 planning approved

NSW Government awarded the $735 million contract to John Holland for delivery of the new Sydney Football Stadium (stage 2 construction)

Stage 1 construction work completed

Commencement of stage 2 construction, bulk earthworks, retaining walls, enabling and temporary works commence

Stadium substructure elements commenced

Structure - basement to concourse level construction commenced

Above concourse level works commenced

Completion of Concourse

Roof, façade, fit-out and remaining elements commenced

Design for stadium seats released

Stadium opening

Nov 2017

Mar 2018

Apr 2018

Apr 2018

May 2018

Jun 2018

Jul 2018

Sep 2018

Oct 2018

Oct 2018

Dec 2018

Dec 2018

Jan 2019

Jan 2019

Mar 2019

Apr 2019

May 2019

Jun 2019

Aug 2019

Aug 2019

Dec 2019

Dec 2019

Feb 2020

Mar 2020

Apr 2020

Jun 2020

Sep 2020

Mar 2021

Mar 2021

Jul 2021

Late 2022

3.6. LIST OF CRITICAL PATH ACTIVITIES

Critical Path Activities

Tenders and Contracts

Planning and Approvals

Site Preparations

Substructure

Superstructure

Install Facade & Roof

Exterior & Landscape

Site Defect Inspection

Building Completion

→ Tenders and Contracts

→ Planning and Approvals

→ Site Preparations

→ Basement Slab Pour

→ Column Pour

→ Ground Slab Pour + Concourse

→ Basement Slab Pour

→ Column Pour

→ Ground Slab Pour + Concourse

→ Pour Stairs

→ Pour Stand

→ Install Structural Steel

→ Polycarbonate Roof

→ Cleaning Site

→ Run & Test System Services

→ Private Certifier to check for Defects

→ Rectify Defects

→ Building Completion

3.7. SCHEDULE CONTROL PROCESS, SCHEDULE UPDATES & REPORTING FORMAT

A Contract Programme will be created to define important milestone dates, actions to meet these milestone dates, and associated tasks in order to monitor and accomplish the project's duration requirements. The Contract Program will be utilised to determine the important path and, as a result, the time-related risks connected with it. The Contract Programme will be revised monthly, or as needed under the Contract, to reflect the project's status. Site teams responsible for the related tasks, activities, and milestones will create status information. If the Contract Program has enough float to identify and act on opportunities, a target programme can be developed. Subcontractors are allowed to create their own programmes that mirror the Contract or Target Program, as long as they adhere to the contract's termsandconditions. Theseprogrammes will beutilised tosteer andidentifythe risks and opportunities that present themselves throughout time. To monitor and regulate the project timeline, the Project Manager will employ a variety of tools and approaches, which are illustrated in Figure 5.

The schedule in Figure 5 depicts the critical path for the new Sydney Football Stadium. According to the contract, the Stadium improvements are scheduled to be completed in early 2022 and the Stadium will be utilised once complete.

Only the Building Services and Aboveground Work activities have permitted float, thus the bulk of the jobs are sequential. As a result of any delays in the Site Establishment or Structural Works, the deadline in early 2022 will not be met. This increased the likelihood of the customer claiming exorbitant liquidated damages. The number of critical route activities is minimised as much as feasible by seeking to begin tasks sooner when a work area becomes accessible. Hence, all of the tasks in the Site Establishment are start-to-finish. As a result, any of these delays will cause Site Establishment to be delayed by the same length of time, delaying the start of the Structural Works and Services.

Furthermore, Concrete Footings and Retaining Walls can be started in the Structure section while the excavation is going on. Thus, a delay in the excavation would have no effect on any of these activities. Following the completion of the Retaining Walls, the Basements Slab (25-day time frame includes curing time) and Superstructure are finish-to-start. After quality checks, structural curing, and sign off, the Internal Fitout may begin two and a half weeks after the Structure is completed. While the Partitioning is being completed, the Wet Area Fitout and Painting may be completed.

Lastly, it is important that projects on the critical route are performed in accordance with the Baseline Schedule in order to avoid causing delays in the other works at the Sydney Football Stadium or the overall completion date. To guarantee that essential activities do not lapse, significant project resources and scheduling efforts will be used. The project and site managers, as well as project engineers, are fully aware of the key path activities and the need to keep them on track.

3.7.1 – PROGRESS MEASUREMENT SYSTEM

The Project team will record and assess the project progress with the following methods:

➢ Milestone-based: accurately assessing and reporting the WBS milestones that are in progress or completed.

➢ Percentage-based: recording the status of work packages that are completed and displayed as a percentage.

3.7.2 – SCHEDULE UPDATES PROCESS

There will be project progress status updates on a weekly basis from main contractors, subcontractors and suppliers. The Project management team will review the updates, identify deviations and manage changes to the baseline schedule in Section 3.4. Furthermore, the team is responsible for updating the work performance data, change requests, schedule baseline updates, lessons learnt and organisational process assets files every week. A monthly project update report will be generated and a meeting will be held to review the reports and ensure that the Project management team’s schedule is accurate and aligns with the contractors and other stakeholders schedule.

3.8. REPORTING

Project planners will report the project progress and effectiveness on a regular basis, compared with the project plan. This is to ensure that if a problem arises, a solution to resolve the issue will come quickly.

Report Type

Week Report

Month Report

Annual Report

Project Closure Report

Time

Every Friday

Every end of month

Every December

End of Project

Person Responsible

Project Manager

Project Manager

Project Manager

Project Manager

If corrective steps are needed to get the project back on track, one of the following activities must be completed to enhance productivity and minimise time :

➢ Project crashing =increasethe project resourcesto shortenthe project duration oncertaintasks. Consequently, project cost will directly increase as more resources are allocated to keep the project back on track.

➢ Fast tracking = executing the project parallelly to shorten the duration of the project instead of completing each task separately.

PROJECT COST & FINANCIAL MANAGEMENT PLAN & COST BASELINE

4.1. OVERVIEW

The purpose of this Cost & Financial Management Plan is to establish a cost framework for the numerous resources needed to accomplish project operations. To get the best outcomes, the main component of cost management planning must be completed throughout the design process. This project's effective cost management planning, which includes the integration of life cycle costing, value engineering, and constructability analysis, will result in a reduction in project cost and time, improved quality and performance, optimised design-to-cost facility performance, and streamlined decisionmaking.

Because the cost of a project is so closely tied to its design, it's critical to keep track of and control expenses as designs evolve.

To correctly estimate and manage a project's cost, the project team must first:

1. Define the project's scope, including a description of the project.

2. Make a list of assumptions and limitations to work with.

3. Determine the project's duration and create a work schedule

Cost estimating, budget determination, and cost control are three essential management stages that are required to manage cost on a project. The first two phases occur mostly during the project's planning phase, whereas the cost control step happens throughout the duration of the project.

The following are the major overall Key Performance Indicators (KPIs) that we will use to evaluate our Cost & Financial Management Plan's success:

➢ Cost estimation - Establishing an accurate cost baseline against which to measure the project's performance, such as if it is behind schedule in terms of cashflow and whether it is over or under budget.

➢ Regular cost reporting – Ensuring that the project's cashflow is continually monitored and managed

➢ Cost change management – Ensuring that the proper processes are created and followed when it comes to budget variances

➢ On budget To keep the project on track.

4.2. COST ESTIMATION & BUDGET DETERMINATION METHODS

Cost estimation in project management is the practice of projecting the cost and other resources to deliver a project within the scope. In order to perform cost estimates for the Sydney Football Stadium, the cost management team has taken into account each project needs, deliverables, and produces a total amount that is used to set the project cost. The estimated amounts are expressed in Australian dollars. However, cost estimates are not very precise due to lack of accurate data on resource quantities and detailed WBS, hence the management team will ensure that the data in the cost management plan is up to date as the detailed plans are available. The following basic methods of estimation will be adopted by the cost management team:

Parametric Estimation

This technique is used for estimating the project duration and cost which uses a statistical link between historical data and other variables. These historical data come from lessons learnt, and similar projects

such as Stadium Australia and Western Sydney Stadium. Depending on the sophistication, quantity of resources and cost data, it can yield higher levels of accuracy than Analogous Estimation.

Bottom-up Estimating

This estimation technique requires estimating tasks at the most granular level possible. In order for the Cost Management Team to arrive at summary totals, estimates are aggregated according to the WBS. The likelihood of achieving the predicted amounts improves significantly when detailed costs and time estimates are developed for a work package. This method takes a longer period of time to complete as they are more accurate than parametric estimates.

Three-point Estimating

This method predicts the likely outcomes of future project occurrences based on available information, which involves three measures, namely the “best-case estimate,” “most likely estimate,” and “worstcaseestimate”.Byincludingestimationuncertaintyandrisks,theaccuracyofsinglepointcost estimates may increase.

Determine Budget:

The project budget is the next step following the calculation and approval of cost estimates. In this part of the cost management plan, the management team will combine the projected costs of different activities or work packages in the WBS to develop an authorised cost baseline. It includes the cost baseline which comprises direct and indirect construction cost, the contingency and management reserves. The project budget can be impacted by organisational rules and policies, guidelines, lessons learnt, historical cost databases and reporting techniques.

The following diagram shows the elements that is used to determine the project budget.

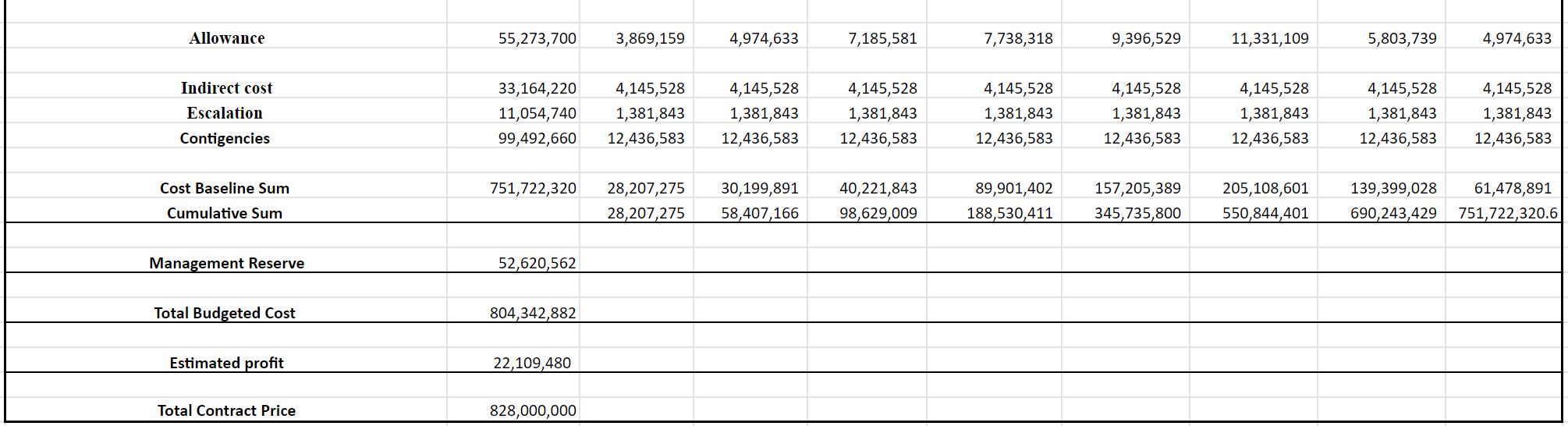

Details of SFS Redevelopment project cost components are listed as below:

Cost Components Amount Description

Construction Work Package (CWP)

Costs

Allowance

Contingency

Escalation

Indirect Cost

Management Reserve

AU $522, 737,000 Construction cost of each individual work package demonstrated in WBS of the project, including the costs of construction materials and transportations, labour, plants, equipment and softwares, staff training and insurances etc.

In the Sydney Football Redevelopment project, the total CWP cost is roughly 69% of the total project budget, estimated by bottom-up method.

AU $55,273,000 An estimated budget added on top of CWP cost to cover the extra costs of construction activities, when the scope of the activities are unknown and cannot be accurately estimated (eg. The extent of the work is unclear at the time the project contract is signed.

TheallowanceforSFSRedevelopmentprojectis10% of the total CWP costs.

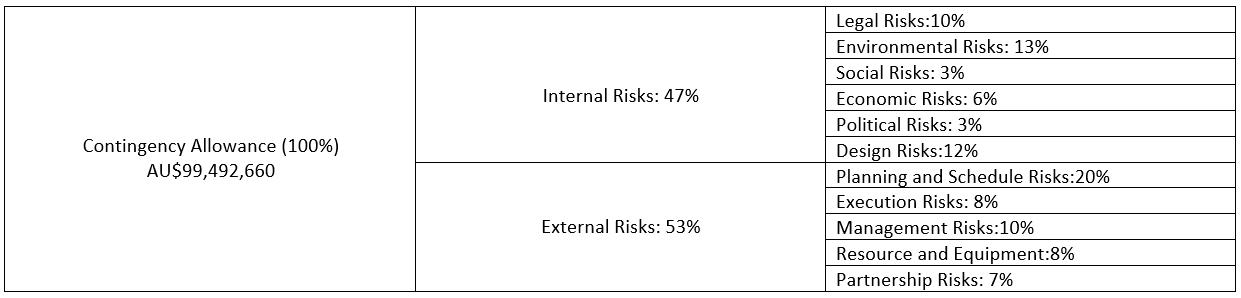

AU $99, 492, 660 Contingency refers to the allowance to accommodate unexpected risk that might occur in the construction project. The contingency will be closely associated with the risk management plan.

The contingency allowance for this Sydney Football Stadium is roughly 18% of the total CWP cost.

AU $11, 054, 740 The anticipated increase in cost of the SFS Redevelopment project over time due to various factors, including inflation, exchange rate as well as market conditions.

AU $608, 010, 700 Costs that are not directly related to the construction activities: taxes, fringe benefits, General sales and administrative (GSA) or General administrative (GA).

$52, 620, 560 The amount of the project budget withheld for management control purposes and are reserved for unforeseen work that is within the project scope. Additional 7% of the cost baseline is added on top of it as management reserve.

4.3. COST BREAKDOWN STRUCTURE (CBS UP TO LEVEL 3)

A cost breakdown structure is developed for the Sydney Football Stadium Redevelopment project, to demonstrate the allocation of project budget to different construction activities and work packages that are identified in the Work Breakdown Structure (WBS) (refer to section 2.3). This ensures the costs of construction activities can be accurately estimated and effectively controlled throughout the construction process, so that the project can stay within its budget. The Stadium Construction Cost Model created by Hein le Roux and Eugene Corrigan (Roux, H. & Corrigan, E., 2014) as well as the Rawlinson’s Australian Construction Handbook 2018 are used as a guidance when estimating the budget for each construction activities of SFS Redevelopment project.

The unit of measurements are as shown below:

Type Applications

Australian dollar (AU$)

Meter (m)

Item (no.)

Square meter (m2)

Cubic meter (m3)

Project budgets

Piping, footing, columns and beams, railings, texture tapes installation

Doors, windows, fixtures, equipment, lifts, precast structural steel installation

Slab, walls, landscaping, roof

Demolition, earthwork

4.4. CASH-FLOW DIAGRAM & COST BASELINE (FOR A 3-LEVEL WBS)

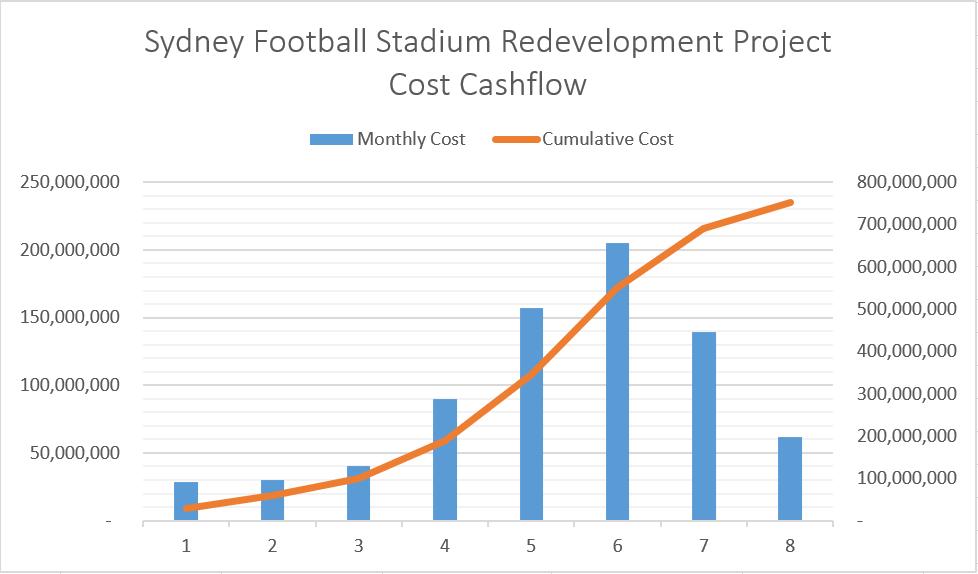

Cost baseline diagram for Sydney Football Redevelopment Project is developed based on the cost components and the CBS provided in section 4.1 and 4.2. By comparing the cost baseline with the actual project costs, the project management team can effectively monitor the performance of the project over the project duration, track for activities that are over budget and make necessary adjustments to the project budget, to ensure the project is within the budget.

4.5. COST MANAGEMENT ROLES & RESPONSIBILTIES

Project Director / Manager:

➢ Planning organising and orchestrating the completion of tasks.

➢ Ensure tasks are on time and within the budget.

➢ Oversee the entire project to analyse and manage potential project risks that may occur and eliminate them.

➢ Reduce cost while maximising efficiency as to have increased revenue.

➢ Ensure all subcontractors understand their roles and responsibilities and supervise them to ensure they are delivering to the desired specifications/plans.

➢ React to problems that may arise on site with solutions and liaise with site team on how problems can be quickly fixed to ensure project parameters are met.

➢ Manage reports and necessary documentation so all legal parameters are met.

Commercial Manager:

The Commercial Manager (also known as the Budget Officer or Fiscal Officer) is in charge of cost management, procurement, site administration, payroll, insurance, office support, and Contract Administration. Their role includes:

➢ Working with the design manager to ensure that proper cost planning is conducted during the design phase to guarantee cost efficient design solutions are generated for all project aspects within the specified Target Price.

➢ Ensure that supply/subcontract agreements, claims, and payments are completed in accordance with established procedures.

➢ Keeping track of the project's accounting and reporting system.

➢ Ensuring the effectiveness of the claim/variation system.

➢ Assisting the Project Manager with cost/expenditure forecasts so that financial reports may be developed.

➢ Keeping the financial database up to date and under control.

➢ On a business level, establishing and maintaining partnerships with subcontractors.

➢ Is in charge of asking Lendlease's finance board for any budget transfers.

➢ Assuring the project's financial viability

➢ Obtaining the necessary permits

➢ Constantly reviewing, analysing, and assessing the budget process, including using computer programmes (frequently updating and keeping financial data/reports).

Construction Manager:

➢ Ensuring all labour resources are coordinated

➢ Arranging for building supplies and equipment to be ordered and delivered.

➢ Engineers, architects, and other specialised or technical trade workers can be consulted with.

➢ Negotiating with all parties involved, including building owners, subcontractors, and property developers, to guarantee that all projects are completed on time and on budget.

➢ Putting in place a coordinated work programme for each location

➢ Creating proposals and tenders for contract work

➢ Local governments are organising construction inspections.

➢ Supervising the work of subcontractors and ensuring that it is completed to a high quality.

Cost Estimator:

An estimator is in charge of attempting to determine the cost of a project. They are in charge of determining each and every expense associated with a project including:

➢ Examining a project's labour, material, and time needs.

➢ Examining the complete project to estimate expenses.

➢ Upper management should be informed of your cost projections.

➢ Preparing reports that describe all of the expenses associated with a project.

➢ Incorporating cost information into the company's database.

➢ Observing the discrepancies between the estimated and real costs.

➢ Examining the project's needs from the perspective of the client.

➢ Preparing proposals with the help of the sales staff.

Contracts Administrator:

➢ Establishing and sustaining connections with stakeholders and suppliers is important because collaboration reduces risk and allows the contract's value to be maximised. As a result, construction is efficient and productive, with continual communication assisting in the identification and management of any possible dangers.

➢ Monitoring performance and resolving non-performance under the supervision of the project manager and the site manager to ensure that work is completed on time and at the highest possible level.

➢ Managing contract risks and updating and approving requests for contract changes to fulfil organisational commitments.Itisthecontractadministrator'sresponsibilitytoevaluaterequests for contract modifications, which may be rejected; complaints must be handled appropriately under the supervision of senior managers.

➢ Ensuring that all stakeholders, workers, and contractors involved understand and comply with contractual requirements and clauses in order to inform all of what is expected of them.

➢ After patent defects have been rectified, changes to the contract sum must have been agreed upon, and all claims must have been settled, certificates of practical completion and final certificate of competition will be issued.

Project Engineer:

➢ Prepare plans with accurate drawings consisting of project specifications and cost estimates.

➢ Design and execute engineering experiments to create workable and effective solutions.

➢ Develop engineering calculations, diagrams and technical reports in relation to the project.

➢ Complete daily requirements such as technical and regulatory documenting.

➢ Ensure projects are completed on time and within the specified budget.

➢ Present analysis results and project solutions to technical management, senior leaders and key stakeholders as necessary.

Contracts Manager:

➢ Contracts must be written, analysed, negotiated, and agreed upon.

➢ Assist in contract negotiations by acting as a single point of contact.

➢ Manage communication, paperwork, and contract records.

➢ Obtain advice on price, business requirements and limitations, and delivery dates from internal subject matter experts.

➢ Identify and resolve contract-related concerns both internally and outside.

➢ Manage contract terminations, such as renewals, cancellations, and renegotiations.

➢ Internal stakeholders should be kept informed.

Site Manager:

➢ Overseeing everyday activities on site, such as material deliveries, and ensuring the safety of all equipment.

➢ Managing onsite issues

➢ Assuring that every work satisfies the client's quality expectations as well as Australian requirements

➢ Putting together programmes

➢ Ensure that all members of the team on site adhere to the WHS guidelines.

➢ Collaboration with architects, engineers, surveyors, and planners.

➢ Reporting on a daily and monthly basis.

➢ Subcontractors and visitors to the site are given inductions.

➢ Identifying hazards and taking necessary action to minimise or reduce their impact on the building process.

Project Scheduler / Planner:

➢ Setting of assignments, tasks, and subtasks with the help of project managers and technical specialists.

➢ Creating, deploying, and maintaining an efficient schedule management system.

➢ Working with internal departments and external stakeholders to coordinate project timeframes.

➢ Timelines and deadlines for projects are being tracked.

➢ Identifying possible project schedule delays and allowing timely action.

➢ Performing performance evaluations and generating project status reports.

➢ Updates and modifications to project timelines are accommodated.

➢ Recommending steps to keep projects on track and under budget.

➢ Project timeframes and deadlines are communicated to all parties.

➢ Maintaining and documenting project scheduling methods.

4.6. COST PERFORMANCE MEASUREMENT (EARNED VALUE MANAGEMENT)

Earned Value Management (EVM) looks at the project cost and schedule performance by analysing cost andschedulevariancetomaximisethecost andscheduleefficiency.TheEVMtechniquesforecasts the future based on anticipated and actual values, allowing project managers to make necessary adjustments. The terms for EVM are as follows :

Performance measure definitions

The Cost Variance (CV) is the difference between the earned value of work performed and the actual cost at the data date

Cost Variance (CV) = Earned Value – Actual Cost

➢ If the result is POSITIVE, project is experiencing an “Under-run” (saving money!).

➢ If the result is NEGATIVE, project is experiencing an “Overrun” (over the budget).

Cost Performance Index= Earned Value/Actual Cost

➢ If CV is POSITIVE, EV > AC, CPI > 1, Cost performance is good as the project is saving money.

➢ If CV is NEGATIVE, EV < AC, CPI < 1, Cost performance is NOT good as the project is over the budget.

The Schedule Variance (SV) is the difference between the earned value of work performed and value of the work scheduled.

Schedule Variance (SV) = Earned Value – Planned Value

➢ If the result is POSITIVE, the project is ahead of schedule or on time.

➢ If the result is NEGATIVE, project is behind schedule

Schedule Performance Index (SPI) = Earned Value/Planned Value

➢ If SV is POSITIVE, EV > PV or SPI > 1, Schedule performance is good as the project is ahead of time.

➢ If SV is NEGATIVE, EV < PV or SPI < 1, Cost performance is NOT good as the project is behind schedule.

The Earned Value (EV), used to be called the Budgeted Cost of Work Performed (BCWP)

➢ Actual Progress% x Budget at Completion (BAC)

Estimated Actual Cost of Completion

➢ Estimate at Completion = Budget at Completion / Cost Performance Index

4.7. COST CONTROL PROCESS

Cost control is key to ensuring budgets are met. Methods of establishing thresholds in the variance response process is to use the earned value management technique, this allows costs to be measured and costs controlled at a detailed work level.

Cost Control Threshold Table:

4.7.1 – COST VARIANCE REPONSE PROCESS

The cost variance response is a direct visual representation that allows for the project to be controlled. It allows CPI scores to be read with a plan of action if goals aren't met.

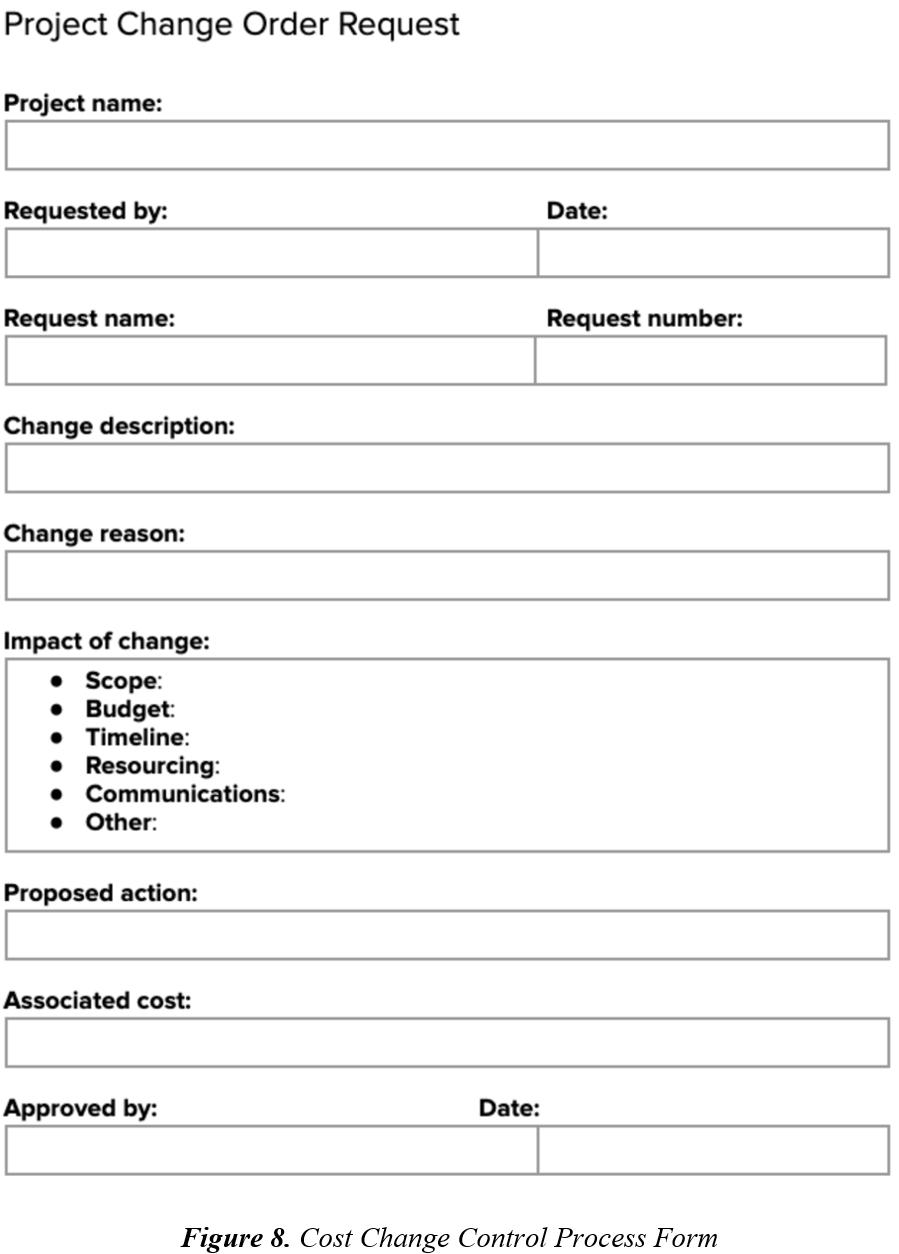

4.8. COST CHANGE CONTROL PROCESS

During the control phase, it may be essential to change the cost baseline at some stages. This is important to ensure incorrect changes will not be considered in the cost baseline. There are 3 steps involved to establish a cost change control process :

Make a change request

Inorder tocreateachangerequest,thepersonwhoismakingtherequest shouldfilltheform ofachange request. All change requests are then recorded to prevent the occurrence of misunderstanding/misinformation in the project team

Assess the impact of change request

The project team should assess what the change request will affect the construction project either positively or negatively in terms of budget, time, and quality. One of the tools and techniques which can be implemented in this process is the Fishbone diagram. Using the fishbone diagram will help to illustrate a variety of causes that are possible to happen and interrelated with the effect or problem. Another tool that is suitable to assess the impact is the cost benefit analysis which is a process that analyse the benefit that the project will get versus the opportunity cost that it must forego. The brainstorming session is also involved in both tools.

Decision to accept or reject the request

After assessing the impact of a change request, the project team will decide whether to accept, reject, or even modify the change request to get the project on track. All decisions will also be recorded to prevent the misunderstanding/misinformation in the project team. All stakeholders should also be notified if there is a change or modification on the construction project.

4.9. REPORTING

Project planners will report the project progress and effectiveness on a regular basis, compared with the project plan. This is to ensure that if a problem arises, a solution to resolve the issue will come quickly.

Report Type Time

Week Report

Month Report

Annual Report

Project Closure Report

Every Friday

Every end of month

Every December

End of Project

Person Responsible

Project Manager

Project Manager

Project Manager

Project Manager

If corrective steps are needed to get the project back on track, one of the following activities must be completed to enhance productivity and minimise time:

➢ Project crashing = increase the project resources to shorten the project duration on certain tasks. As a consequence, project cost will directly increase as more resources are allocated to keep the project back on track.

➢ Fast tracking = executing the project parallelly to shorten the duration of the project instead of completing each task separately.

Unfortunately, these techniques will most likely affect the project budgeted.

PROJECT RESOURCE MANAGEMENT PLAN

5.1. PROJECT ORGANISATIONAL BREAKDOWN STRUCTURE (OBS)

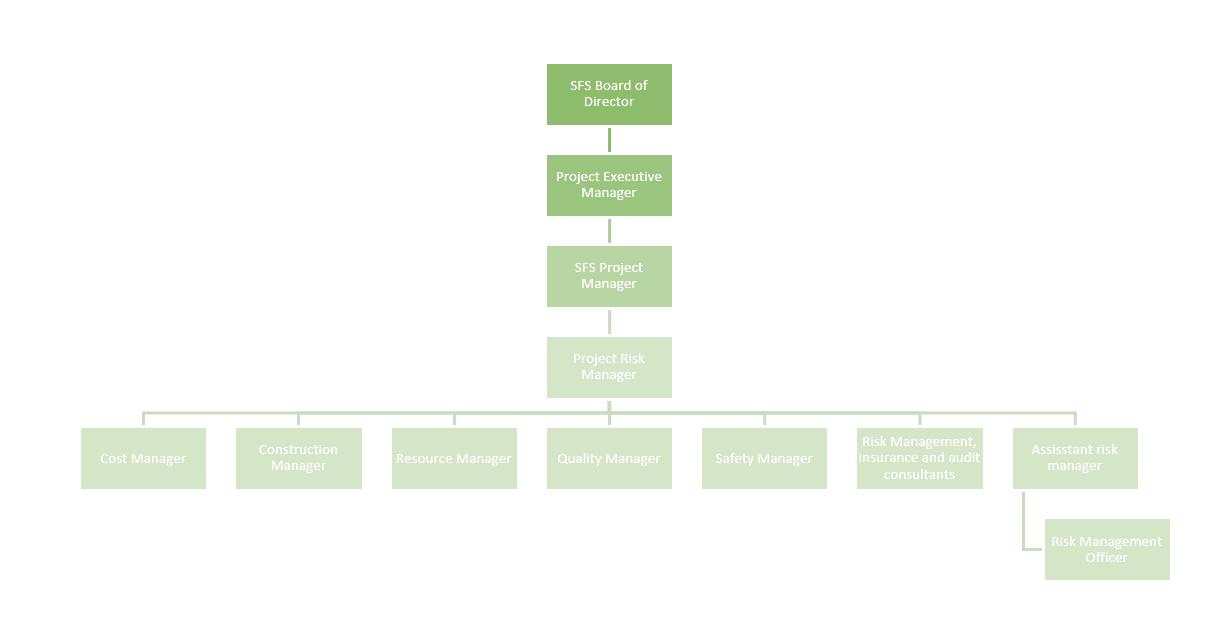

An Organisational Breakdown Chart is developed for the Sydney Football Stadium Project Team, to identify the hierarchical breakdown of the project team structure and illustrate the project team management strategy. The SFS Redevelopment Project OBS contains six levels, which are listed below in order of highest (level 1) to lowest (level 6):

➢ Level 1: SFS Board of Directors

➢ Level 2: SFS Project Executive Manager

➢ Level 3: SFS Project Manager

➢ Level 4: SFS Key Project Management Team Member (E.g. Safety Manager, Risk Manager, Construction Manager, …, Cost Manager).

➢ Level 5: Project Support Team (E.g. WHS Manager, Environmental Health Manager, …, HR Manager, Financial and Operation Manager).

➢ Level 6: SFS Project Support Team Assistant (E.g. WHS Officer, Environmental Health Officer, …, Quantity Surveyor, Accountant).

The project authorities are assigned to various levels of the project team reporting line. Each level of the OBS reports directly to the level above it, e.g., the Assistant HR Manager (level 6) reports to the HR Manager (level 5).

5.2. ROLES & RESPONSIBILITIES

Project Manager (PM):

Responsible for the successful delivery of the Sydney Football Stadium Redevelopment Project. The PM signs off contracts and authorises all expenditures. The PM is responsible for planning, organising and orchestrating the completion of tasks. The PM is also responsible for overseeing the entire project to analyse and manage potential project risks that may occur and eliminate them. The PM is to ensure that all subcontractors understand their roles and responsibilities and supervise them to ensure they are delivering to the desired specifications/plans. Additionally, the PM is responsible for managing reports and necessary documentation so all legal parameters are met. Skills that the PM must have are: Microsoft Project, communication, leadership, project management, negotiation and scheduling.

Design Manager:

The Design Manager is in charge of overseeing the design process to ensure that all design papers are generated to the appropriate standards, on time, and that the relevant designs meet RP's safety, quality, and risk management criteria while being cost efficient. The Design Manager is responsible for establishinga preciseschedule of design deliverables withthePM,and designing packages. The Design Manager is also responsible for identifying technical solutions that allow programme and/or cost advantages to be realised while still meeting RP's health and safety, quality, and environmental risk management standards. The Design Manager must possess the following skills: design skills and knowledge, engineering science and technology, analytical thinking, computing and software and leadership.

Construction Manager (CM):

The CM is responsible for overseeing the overall construction project from initial planning phases all the way through to completion. The CM authorises engagement of subcontractors and manages their work to achieve targeted outcomes. The CM is also responsible for ensuring all labour resources are coordinated, building supplies and equipment to be ordered and delivered, and creating proposals and tenders for contract work. Additionally, they are to supervise the work of subcontractors and ensure that it is completed to a high quality. The CM also has the responsibility of negotiating with all parties involved, including building owners, subcontractors, and property developers, to guarantee that all projects are completed on time and on budget. The CM must have the following skills: time management, effective communication, critical thinking, coordination and monitoring.

Environmental Health and Safety Manager:

EHS coordinators seek to instil a safety culture in their businesses. They put in place procedures, policies, and evaluations to guarantee their firm follows all federal and internal health and safety regulations. The EHS manager is responsible for developing and maintaining programme budget for administrationandmanagement ofhealthandsafetyprocedures,and mustauthorizespendingofmonies within subgroup programme budget. The EHS coordinator has the responsibility to inspect and identify hazards, and EHS infractions, they also create and submit health and safety compliance paperwork to the appropriate authorities. The manager is also responsible for making paperwork for assessments, incident and accident reports, and health and safety guidelines, and keeping up with the latest EHS practises. Skills that the EHS coordinator must possess are: knowledge on environmental laws and policies, analytical thinking, problem solving, writing and effective communication, Microsoft office, and attention to details.

Contracts Administrator:

The contracts administratoris responsible for establishing and sustaining connections with stakeholders and suppliers is important because collaboration reduces risk and allows the contract's value to be maximised. The contracts administrator authorises and certifies contractor’s interim payments. The

contracts administrator has the responsibility of monitoring performance and resolving nonperformance under the supervision of the project manager and the site manager to ensure that work is completed on time and at the highest possible level. The contracts administrator is also responsible for managing contract risks and updating and approving requests for contract changes to fulfil organisational commitments. Additionally, the contract administrator is required to evaluate requests for contract modifications, which may be rejected; complaints must be handled appropriately under the supervision of senior managers. The contract administrator must have the following skills: negotiation skills, accounting and finance knowledge, communication, analytical and problem solving, organisational and time management skills.

Project Engineer:

Project engineer is responsible for planning, organising, and overseeing the development of civil engineering projects. The Project engineer authorises and suggests approval of project procedures as needed. The engineer has the responsibility to prepare plans with accurate drawings consisting of project specifications and cost estimates, and ensure that projects are completed on time and within the specified budget. The project engineer is also responsible for designing and executing engineering experiments, developing engineering calculations, diagrams and technical reports in relation to the project. In addition, the engineer is required to complete daily technical and regulatory documenting, present analysis results and solutions to technical management, senior leaders and key stakeholders. The skills that the project engineer must have are: mechanical engineering, civil construction, earthworks, IT skills, communication, and decision making.

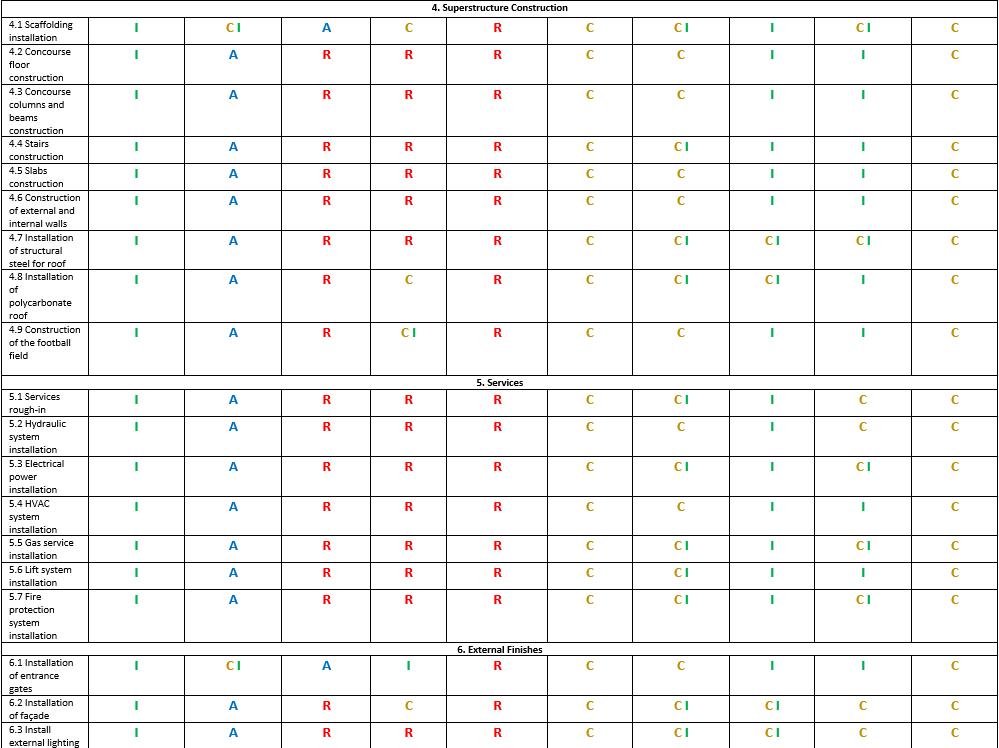

5.3. RACI MATRIX

An RACI Matrix is created to demonstrate the project team's proposed responsibility assignment in completing the work packages for the Sydney Football Stadium Redevelopment Project. The OBS presented in section 5.1 is linked to the RACI Matrix, in order to effectively identify the corresponding responsibilities of the hierarchy of team roles for delivering the project work packages. The RACI Matrix and the legends are as shown below:

R = Responsible – indicates the employees who are responsible for completing the work packages

A = Accountable - indicates the employees who are accountable for the work packages

C = Consult - indicates the employee who are responsible for assisting with the delivery of the work packages, and will be consulted in regard to the work packages

I = Inform – indicates the employees who will be kept informed in regard to the status of the work packages

5.4. RESOURCE AQUISITON & RELEASE PLAN

5.4.1

– STAFF ACQUISITION & RELEASE PLAN

The resource requirements for this project, such as informal processes, are to be determined by Senior Management and include meetings, inspections, anticipated tender possibilities, and management evaluations.Seniormanagementmustensurethatenoughresourcesareavailabletosatisfyprojectneeds and keep the IMS running smoothly. Human, infrastructure, operating environment, monitoring and measurement, and corporate knowledge are all examples of these resources.

The acquisition process will be centred on filling all project roles for the duration of the project. The company's available resources will be chosen first; for the remaining jobs, we may either hire new workersorcontractthemouttoathirdparty.Themannerofemployment willtakeintoaccountelements such as the project's duration and the organisation's general structure and thus, the human resources department will guarantee that we have enough resources and will design new position recruiting methods.

To meet the project’s human resource needs, we have employed various recruitment methods to recruit employees for the Sydney Football Stadium Redevelopment Project. The project manager will firstly work with the human resource manager to create job descriptions including the job title, location, workinghours,salaries,responsibilities, experiences,minimumqualification,andadescriptionofJohn Holland’s mission. The PM will then execute the recruitment plan by advertising the job on the company’s website, on Seek, Indeed, LinkedIn, and other platforms. Furthermore, the HR department will review the applicants’ resume, conduct phone screenings and interviews, contact references and make an offer if all requirements have been met.

The company have employed the following methods to recruit project team members:

Pre-Assignment

In the initial phase of the project, several roles have been determined within John Holland in advance, this is because their skills, knowledge and experiences are competent to deliver theproject successfully. This reduces the need to hire new employees when the right staff is available. Additionally, preassignment of resources allows the company to determine whether there is a need to recruit more staff or delay the project until the right personnel is available.

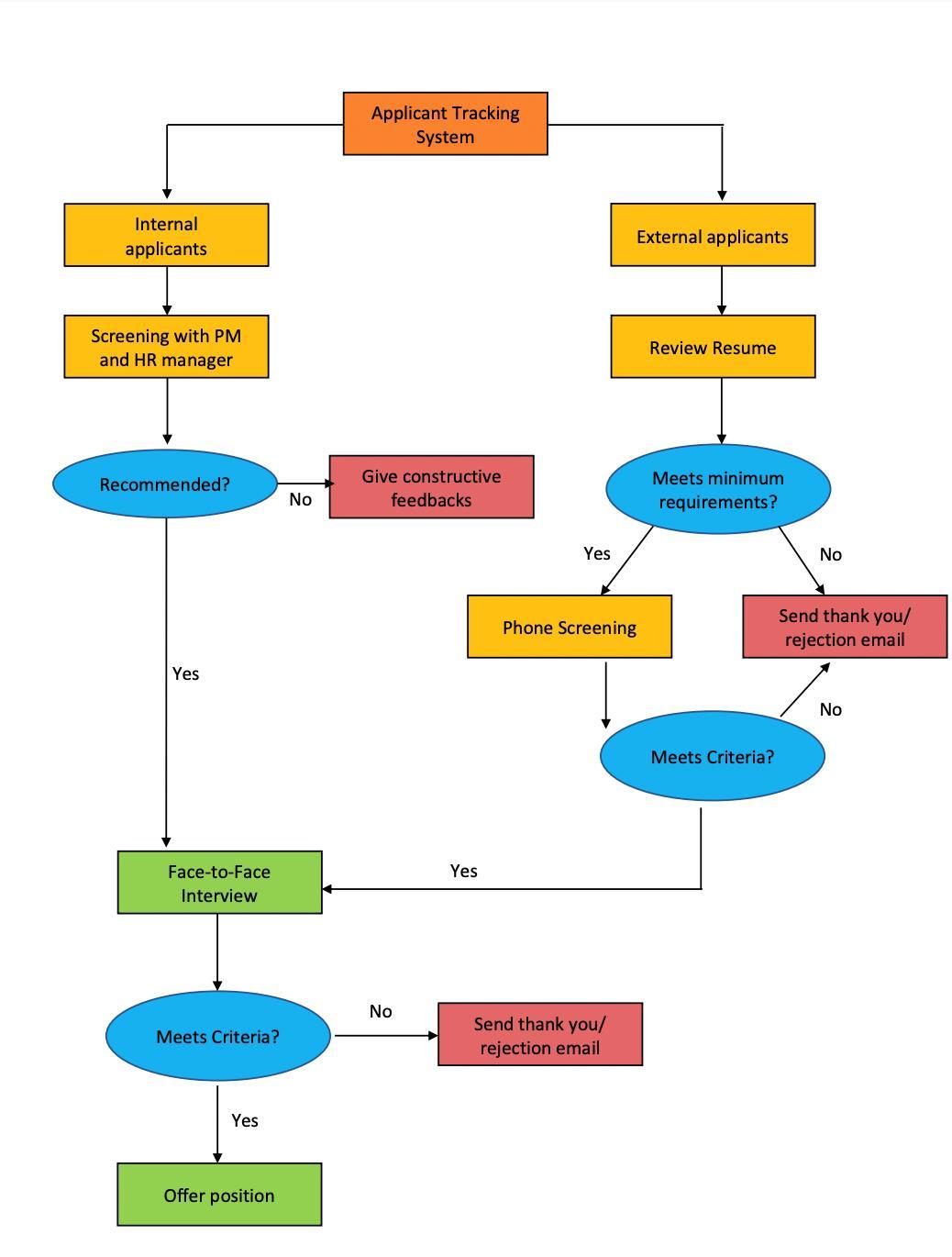

Internal Recruitment

This is the process of recruiting personnel from the existing workforce of John Holland. The human resourcemanagerwillhavetheinternaljobboardrunninganduseanApplicant TrackingSystem shown in the flowchart given in figure below, to keep track of the hiring process. Senior managers may nominate employees or encourage employees to apply, and a screening process will take place with the PM and HR manager present. The qualified candidates will then be assigned a position in the Sydney Football Stadium Redevelopment Project, while the unqualified candidates will be given constructive feedback.

External Acquisition

This process takes place after the internal recruitment, when insufficient expertise is available within the company, we will acquire more staff from the external labour market. The HR department will identify the hiring needs with the PM, advertise job vacancies, review resumes, conduct interviews and offer positions to the personnel’s that have met the minimum requirements of the job descriptions. Although newly recruited employees may take time to familiarise themselves with the working environment and assigned tasks, they may bring in new ideas and skills.

The following flowchart illustrates the staff recruitment process:

5.4.2 – RELEASE PLAN

We'll try to distribute materials as quickly as feasible towards the end of the project and employees whose jobs have lower workloads will be assigned work from other internal initiatives. Contractual / subcontractor work shall be completed in accordance with the contract agreement and the earlier a task/ scope of work package is finished, the more probable the resource will be released from the project.

5.4.3 – RESOURCE CALENDAR:

5.6. MACHINERY & EQUIPMENT CALENDAR & HISTORGRAM

The machinery histogram/calendar record used to forecast the amount of machinery and equipment needed to finish the project. It depicts the amount of hours necessary for each piece of machinery and equipment during the course of the project.

5.7. STAFF INDUCTION

For Employees Working For John Holland:

Before starting new employment, an employee must complete the following checklist. The employer must make certain that the following steps are followed as part of the induction process:

➢ Before the employee's first day, the employer must inform them of where, when, and who they should report to, as well as whether they need to bring any tools or equipment.

➢ Organise building and IT access, as well as uniforms (if needed).

➢ A signed copy of the engagement letter received.

➢ The employees tax file number declaration, superannuation plans, bank details, emergency details, a copy of necessary licenses and “Fair Work Information Statement”, passport or working visa must be attained and saved in the company’s system.