If

If

Andreas Koch

Cluster Design & Innovation Manager

Fronius International GmbH is a family-owned Austrian photovoltaic manufacturer based in Pettenbach, Upper Austria

Fronius is now represented with 37 subsidiaries on five continents with approx. 7000 (2024) employees worldwide and a last year sales of 1.6 billion euros

Fronius is active in:

• the fields of welding technology (beginning in 1950)

• Photovoltaics and all parts related to solar energy

• battery charging technology (beginning in 1946 by charging car batteries)

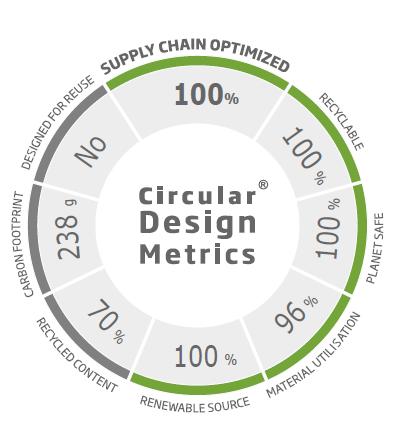

Fronius sustainability goals:

intelligently

A compact, 3-in-1 solution:

• it is the first single-phase inverter power source

• multiprocess-capable, bringing together MMA, MIG/MAG and TIG in a single device.

• having the smart design:

o ease of use

o robustness

o a high level of reliability.

• Weighing 15.5 kg, but this is one of the lightest devices on the market

Expectations:

• Welding machine has to be ready for worldwide transportation

• Transport pack have to be ready for E-commerce-, Truck-, Shipp-, Plane- and Palett transportation

• Drop-test according to the DPD guidlines

Challenges:

• 15kg welding machine has to pass the DPT drop test for e-commerce shipping

10 free falls from 90cm height on all 6 surfaces, 3 edges and 1 corner

• We also have to pass the vibration test in accordance with DIN EN 28318

• Packaging process has to work in under 1 minute with pre-erected parts!

• Modularity!!!

• Development process with 3d file from the customer

• Pass the DPD drop test

• Fix the solution in the packaging concept without touching the ground / sides

• Same structural design concept for simliar solution of welding machines

Closing the bottom with 50mm plastic adhesive tape. Fold side parts an fix it with the bottom tray

Inserting the 15 kg welding device into the side panels and carry it into the outher box

Inserting accessory tray for inserting one accessory variant (three are possible)

Advantages of DS Smith solution

• Plasticfree packaging solution • Cost savings in case of assembling time • Ready to use elements (tray will be used for other products too)

• Customer needs met • 100% recyclable packaging solution