Smarter Tech. Sharper Strategy. Stronger Leadership.

Co-organiser:

Tom St John tstjohn@nineteengroup.com

I’ve strategically put myself forward for this opener to our Q4 issue. I’ve actually done this for the last few years now. Why? Because I can just use up my 500 word limit talking to you about The Manufacturer Live!

I get a buzz of excitement at the thought of you reading my words while standing in The Titanic Hotel in Liverpool. Perhaps you’re perusing through this edition before taking your seat for the start of our Manufacturing Leaders’ Summit.

Perhaps you’ve just walked into a humming and expectant conference room, and I’ve greeted you on the way to your seat. I am always heartened to see so many willing leaders and decision makers - united in their ambition to move the sector forward - gathered in one room, ready to go.

If you are on-site in Liverpool, you will be in a room, and around a table, with like-minded folk. While there may be a vast number of manufacturing industries coming together, it’s remarkable how similar your challenges often are.

And having sat at roundtables in previous years of Manufacturing Leaders’ Summit, it’s fascinating to witness those lightbulb moments. Once people establish that common ground, you would be amazed at how open business leaders can be.

Expect an amplified focus on real-world solutions and industry-leading insights. Once again, we have crafted the highest calibre of speakers, and we have more case studies and interactive sessions, and more networking opportunities for all attendees. Check out our pre-summit preview on page 26

And after those two days, it’s The Manufacturer MX Awards on the evening of 12 November and we’re giving you a taste of what to expect from the night in this issue. My colleagues and

I have travelled the length and breadth of the UK to moderate the judging of the categories for these awards, and collected the thoughts of finalists and judges alike. You can check these out on page 14

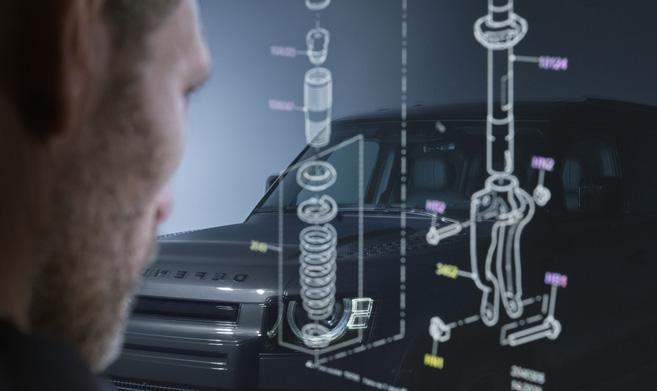

The achievements of those who have entered the awards have been accomplished against the backdrop of continued challenges. Once again, 2025 has thrown up some not insignificant bumps in the road for the sector. Indeed, some of this year’s finalists have themselves been directly impacted by the cyber attack on Jaguar Land Rover in September.

At the time of writing, the automotive giant has only just begun a phased restart of operations and we’re yet to truly comprehend the full fallout from this particular incident. We know full well that cyber attacks are becoming more and more common within the manufacturing sector. And to that end, we’ve put together a ‘how-to’ guide for this issue around the topic, where we look in greater detail at the various types of cyber attack and how they are evolving, ask what the risks to businesses actually are and best practice in how to mitigate them. Go to our lead feature on page 4

Manufacturing’s resilience is tested time and time again and this is yet another body-blow to add to the history books. But from these disasters, the UK’s best emerge. Businesses, large and small, who not only survive, but somehow thrive.

Inspiration and excellence are still very much alive in manufacturing and we must celebrate that fact. Has there ever been a better time to shine a light on industry success?

We look forward to seeing you in November.

C D E M

@TheManufacturer www.themanufacturer.com

Jonny Williamson INDUSTRY ANALYST

Henry Anson DIRECTOR

Ashley Oulton

CONFERENCE PRODUCTION MANAGER

Stuart Biddle

STRATEGIC ACCOUNTS

Grace Gilling MANAGING DIRECTOR

MANAGER

DIRECTOR & HEAD OF SALES

Protecting your factory floor from digital threats has never been more important, as the recent high-profile breach at Jaguar Land Rover (JLR) has shown. In this practical guide, Molly Cooper explains the essential steps manufacturers can take to strengthen their cyber security, safeguard operations and keep production moving

Cyber security is the practice of protecting systems, networks and programs from digital attacks.

These cyber attacks are usually aimed at accessing, changing or destroying sensitive information; extorting money from users through ransomware; or interrupting normal business processes.

Within manufacturing there are unique elements that are present such as manufacturing and production processes, operational technology and critical national infrastructure that also require protection.

Typically, production processes run on a separate network to corporate operations, but the concerns they have should be the same as any other business.

Attackers are not always looking for specific manufacturers, they are looking for the most vulnerable.

The current landscape

Once upon a time, cyber security was not an issue for manufacturers. Many older and more traditional industries were not connected via online systems; they had human operated machines, with on and off buttons. There was a

far greater reliance on mechanical and analogue systems than digital or software driven processes. Now however, cyber criminals have cottoned on to the fact that manufacturers are increasingly digitising their operations and as such, have a plethora of avenues to access and potentially exploit.

Not only that, but the landscape of cyber attacks has also evolved. Years ago, hackers would target large financial institutions and government agencies, but now ransomware, phishing emails and supply chain attacks are far more common within manufacturing. In the last few years financial services firms have invested heavily in cyber security and are now very well protected in comparison to manufacturing, which has typically not been as tuned in to the risks and dangers and as such, is now the most targeted sector for cyber criminals.

These ne’er do wells also have more financial incentives than ever before, with many criminals choosing this type of activity for this reason. Ransom amounts and extortion prices from the threat of selling stolen data are a few of the methods in which criminals can financially

gain from the attacks. Cyber crime also knows no boundaries; it can take place anywhere in the world, from anywhere in the world - meaning investigations and prosecution can be extremely difficult for law enforcement to undertake. Cyber criminals now have the advantage, as it is easier to attack than defend.

Cyber security has flown under the radar for manufacturers for many years. The absence of a need for cyber security in previous generations has resulted in a lack of awareness around the topic, and therefore, there has been a dearth of investment in that area. Related to the growing skills gap within manufacturing, many firms do not have the necessary cyber security expertise and experience in-house to get the business up to speed on the current landscape.

Yet, even with protection, the ways in which attacks are evolving means that manufacturers are often trying to hit a moving target. It is unrealistic to assume that your operations are impenetrable, so it’s about having a robust response plan and knowing the steps that you can take to make sure you can recover as quickly as possible.

Manufacturers have employee, customer and operational data that they need to protect, but often the question is, how?

Hackers are looking for any compromise in a business system to then hold it to ransom. This is called ransomware and is the most popular kind of attack on manufacturing businesses in the current climate. In fact, the first quarter of 2025 alone saw ransomware incidents in manufacturing surge 46%. This can cause manufacturing processes to shut down and cost businesses millions of pounds per day, or in some cases per hour. The hacker’s aim is to push the business into a corner where they will have no other option but to respond and pay the ransom to ultimately save the company.

So how do we stop this from happening? While no one can claim to be 100% secure, companies need to ensure that there is no compromise to be found in the beginning and they can do this with correct cyber prevention techniques. When it comes to cyber security, prevention is better than cure. By ensuring all your windows and doors are closed, you leave no route for hackers to get into your business and the chances of a company’s data being breached become much less.

Vulnerabilities in servers and technology are still the most harmful aspect of cyber attacks. On the market there are many intelligent technologies and solutions available, plus post-incident support and forensics for businesses to implement which can provide notifications if and when an attack occurs and help find the cause. However, most businesses could spend less on preventative methods to stop the attack happening in the first place.

Cyber security experts stress that nothing is fool-proof when it comes to cyber security solutions. A prime example is banks who spend tens of thousands of pounds each year on cyber security systems and still we read stories in the news of breaches.

However, a manufacturing company that only performs the basics to keep its systems patched is more likely to be targeted than those who are using prevention techniques and competent response systems.

Types of protection

Preventative methods/penetrative testing: This is a security exercise where a

Ransomware remains the biggest threat to businesses and can strike both randomly and strategically.

According to a World Economic Forum report (April 2025), cyber attacks on manufacturing accounted for 26% of global attacks, with 71% being ransomware. In 2023 alone, attacks on industrial infrastructure doubled, threatening supply chains and production. Hackers often target multiple manufacturers to identify the most vulnerable. Once systems are compromised, they demand a ransom to stop the attack, and some companies pay to prevent financial loss, production downtime and brand damage.

Insider threats are another major concern. Employees are an organisation’s biggest asset but can inadvertently or intentionally compromise systems. Most insider incidents occur through phishing, where attackers send emails or messages with malicious links. Modern phishing is increasingly sophisticated, often appearing to come from colleagues via subtly altered addresses or relevant messaging. While IT staff may be trained in cyber security, operational technology (OT) employees may prioritise efficiency over security. Regular training on the latest attack vectors helps instil a stronger cyber culture.

Viruses, worms and trojans are types of malware that disrupt, damage or gain unauthorised access to systems.

• Viruses attach to programs or files and spread when opened or shared by users. They can write their own code, infecting multiple files across a system.

• Worms can spread independently across computers via the internet or LAN, replicating rapidly to create massive disruption.

• Trojan horses appear as legitimate software but are malicious, allowing hackers entry and enabling further attacks.

Spyware infiltrates systems to collect data without user consent. Stolen information can be sold to advertisers or cyber criminals and sometimes leveraged for ransom.

Denial-of-service (DoS) attacks overwhelm servers with excessive traffic, making services unavailable.

Distributed DoS (DDoS) attacks amplify this effect using multiple compromised systems, aiming to render websites or networks completely unusable.

Even with these threats, internal weaknesses often enable attacks. IT and OT vulnerabilities are rising due to their increasing convergence in global manufacturing. Traditionally, business networks, emails and cloud storage were separated from industrial control systems. Today, digital transformation creates interconnected gateways, allowing attackers access to multiple systems.

Supply chain vulnerabilities are another weak point. A single compromised supplier can introduce malware into a manufacturer’s network, often exploiting third-party software or hardware used in production.

Businesses need to be looking at who they are working with and how secure their systems are. No one entity has ownership over the whole supply chain - despite the fact that it is intrinsically connected – and as such, responsibility for cyber security up and down the supply chain is distinctly opaque. Businesses need to understand their footprint; even though one supplier may be the victim of an attack, a different business may well be held accountable.

company hires cyber security experts to attempt to find and exploit vulnerabilities in their cyber systems - also known as ethical hacking. After a penetrative test, the ethical hacker will share their findings with the target’s security team and make them aware of any weak spots before an attacker does. They will then take action to repair them.

For some experts, this is seen as the best form of cyber security a business can have and is the best way to be proactive in your business. It strengthens cyber resilience while helping to identify flaws within your systems in a safe way.

Automated threat detection and response systems: The primary objective of these systems is to reduce the time a threat remains within a company’s network before it is identified and addressed, as well as enabling organisations to identify and respond to them as they occur. The system will immediately notify the security team, and a decision can then be taken on whether or how to respond, or an automated, targeted response will be deployed.

Real-time threat detection includes continuous monitoring, automated alerts, integration with security tools, AI and machine learning and incident response.

For manufacturers these systems can minimise downtime due to rapid detection and prevent production halts, enhance security protecting critical assets, aid regulatory compliance and reduce the burden on internal security and IT teams. However, this is only triggered when an attack or suspected attack is, or has occurred. Outside of an attack, the software works in the background searching for threats, and does not test systems or improve existing security.

Cyber security insurance: Also known as cyber liability insurance, it protects businesses from financial losses resulting from cyber attacks such as ransomware and data breaches. In brief, there are two types of cyber insurance coverage and it is important to discuss with an insurer which would best suit your company’s needs.

First-party cyber coverage covers legal counsel, recovery and replacement of stolen data, loss of income due to business interruption, crisis management and PR, cyber extortion and fraud, service to investigate breach and fines related to incidents.

Third-party cyber coverage covers liability if a third-party brings claims

against the impacted business. This could be an entity within the supply chain or a partner. This cyber coverage covers the legal defence of the suit and costs of the settlement. This covers affected payments to consumers, claims, settlements from lawsuits, copyright or trademark infringement and accounting costs.

Cyber security insurance works best in conjunction with other cyber security protection. If a business can prove that they have other measures in place and are continuously testing their systems, as well as addressing and identifying vulnerabilities, it can result in lower insurance premiums.

Less downtime: When machines are off, businesses lose money. A cyber attack can place machines out of action causing a halt in production. If products are not being made, customers can become agitated and may begin to look elsewhere for what they need. This also causes reduced productivity and loss of profits. If preventive measures are in place a company can stop an attack before it happens or know how to recover if it does.

Secure intellectual property: Intellectual property is often of huge importance to manufacturers. Once your system has been infiltrated, intellectual property is breached and can be shared. Maintaining system integrity is crucial to ensuring that processes remain protected. By securing intellectual property, manufacturers can safeguard their research and development investments, and maintain trust with partners and customers without fear of compromise.

Brand loyalty and customer satisfaction: It is never an easy conversation to tell your customer base that your database has been hacked and the production line has been halted. Not only that, but for large corporations there is the possibility that a security breach could make local or national news, portraying the company as unsecure, incompetent and an easy target. Customer trust and respect is vital for a thriving and growing business.

Lower recovery costs: No cyber attack protection is fool-proof but implementing prevention technologies can greatly reduce the risk of being attacked.

Companies do not need to spend millions of pounds on intrusion detection systems even though the market is full of disaster recovery and incident response

“

Most businesses could spend less on preventative methods to stop an attack happening in the first place

providers. Operationally, manufacturers need to prevent incidents before they happen to protect themselves from fines and loss of business.

Any business will struggle to justify a large spend on something that has never – or may never - happen. Many would prefer to invest in new projects or marketing campaigns. However, the cost of prevention measures will be far cheaper than the cost of getting a business back on its feet following a cyber attack

The best solutions are not always the most expensive, but when it comes to cyber security, some businesses believe the more you pay the more protection you get. However, cyber security is not a one-sizefits-all solution.

Large enterprises typically face more complex challenges requiring bigger, scalable solutions and frameworks to work against. Often, they will spend millions on a solution, a consultancy to implement and manage it and another system that logs all activity and continuously searches the network for threats and signs of compromise. This is all very useful and can be a great asset to large businesses when questioning an IP address they don’t recognise or unwanted communication with a system in another country.

Small businesses cannot always afford to spend that much on threat intelligence systems however. But there are ways they can use what money they do have wisely. Supply chains and systems can be smaller and wider global issues not as relevant. Their focus is securing their network, and this can be done through continuous prevention testing with automation.

Manufacturers have been attacked all over the world and will continue to be targeted as they become more connected. Manufacturers will always be prime targets due to their new reliance on interconnected systems spanning multiple locations, the valuable intellectual properties they own and the high-value data they store. Here are some examples of attacks that have occurred in the sector during the last ten years.

Reckitt Benckiser Group

Hit by Goldeneye ransomware in 2017, causing $117m in losses and disrupted production via compromised tax software update.

Volkswagen Group

Suffered multi-year data theft (2010–2015), losing 19,000+ sensitive engineering documents, breach acknowledged in 2024.

Dole Foods

February 2023 ransomware attack stole 3,885 employee records and shut down North American operations, costing $5.7m.

February 2024 ransomware targeted Automotive Body Solutions; production halted and threat contained early.

Jaguar Land Rover

September's cyber attack paused production in multiple countries causing £50–72m weekly losses, some company data affected.

Commenting on the recent JLR cyber attack, Shankar Haridas, Head of UKI, ManageEngine said: “The JLR cyber attack is a stark reminder that even the strongest brands are vulnerable when security isn’t embedded as a core business strategy. Manufacturers must recognise that every supplier connection represents a potential risk, and only by making cyber security a board-level priority can they build the resilience needed to withstand today’s AI-driven threats. Security can no longer be treated as a bolt-on and it must be woven into the very fabric of business operations.”

Although AI and machine learning do play a role for the bad guys, it can also play a virtuous role for businesses too. Cyber security companies can implement automated defences, meaning that systems can be tested without any manual intervention from the provider or business. In turn, costs can be reduced, and businesses will only spend when prevention testing finds an issue that needs investigating.

Smaller businesses tend to be smarter with their money because they have to, while larger corporations can easily splash on the ‘complete’ system, even if it isn’t. Preventative testing can cost pennies in comparison, and no matter how big or small a business, prevention is always better than cure.

mistakes manufacturers make

A failure to understand the inherent risks is a major stumbling block for manufacturers. Cyber security is often a blind spot for those in the industrial space (as evidenced by the low volume of manufacturers that are considering it a priority). And with the growing convergence between IT and OT, those risks are only going to increase. However, for the most part, businesses

are forgetting to protect themselves from digital attacks.

Currently, most companies do not have any strategies in place and even though they may know how to react in an attack, they do not know how to recover. This suggests many would just pay the ransom to get things up and running again, but what about the losses?

is an expert and anyone can fall for a phishing email, especially at a time when they are becoming more convincing than ever. That’s not to say that areas of attack have to be overly sophisticated. Something as simple as poor password management can open the door to malicious actors.

Many manufacturing businesses will have shadow IT, in other words, assets in their technology landscape that have been forgotten about. An example of this is a server or cloud storage being created for a project for a dedicated timeframe and then never used again; or, if the owner of that cloud storage leaves the company and the login is no longer in use. Assets such as these can be easily compromised, providing a route into the inner workings of a business that employees and the leadership team weren’t even aware of. This is an area of risk.

Understanding these areas is key because businesses can then allocate budget to the most vulnerable sections of the company. In this case, it could be employee training. It is unrealistic to assume everyone has good cyber security awareness and with some employees, the workplace could be the only environment where they use technology. Not everyone

Recent research by Omdia found that cyber attacks are on the increase in manufacturing with 80% of firms experiencing a significant increase in overall security incidents or breaches last year. Yet still, many manufacturing businesses have admitted that the cost of cyber security systems is prohibitive – especially for something that isn’t going to be a revenue generator; why would it be a priority if it doesn’t make money for the business?

It’s wrong to assume that because a business doesn’t hold any sensitive materials, it must be safe from hackers

And it’s wrong to assume that because a business doesn’t hold any sensitive materials, it must be safe from hackers. It’s true that some attackers focus on potentially lucrative sectors with sensitive information such as defence, oil and gas, for example. However, if a manufacturer (or any business) creates revenue, this can work as leverage for a hacker who knows they can stop that business from making money and

hold a ransom cost over its head.

A common anecdote is that while CEOs and CISOs (Chief Information Security Officers) are concerned over cyber security issues, they struggle to get boards to invest in them. But often, when presented with a real-world analogy, they begin to look at things differently; and recent events will certainly make it a topic that's hard to ignore.

No matter how big or small a business, prevention is always better than cure when it comes to cyber security

Alarms and security cameras will of course be installed around the perimeter of a factory. And employees are trained to only use their own passes or security codes for doors. They are instructed not to let anyone freely enter the building and make sure they ask for ID when they do. Proper and secure lockdown of the facility is ensured each night by closing and locking all doors and windows. This makes it difficult for anyone to enter without permission.

In short, manufacturers tend to have their houses in order when it comes to security and IP in the physical world, so why would the same approach not be applied to IT systems? Why leave cyber doors open for hackers to enter and steal the company’s data. Businesses don’t wait to be burgled before setting up physical security systems, so why wait until a breach to install cyber resilience?

Don’t leave visible vulnerabilities in technology and create an easy target to exploit. l

Thanks to:

Darren Anderson, UK Director, Osec

Darren Anderson leads UK operations at OSEC, an offensive security firm specialising in penetration testing and breach simulation. With years at Dell SecureWorks and NCC Group, he has extensive cyber security experience, covering ethical hacking, compliance, and risk management. He advocates for proactive security, emphasising continuous testing through OSEC’s Incenter platform to prevent breaches before they happen.

As a manufacturer it can be difficult to implement cyber security systems due to the complexity of integrating security into existing legacy systems that were not designed with cyber threats in mind. Not only that but manufacturing operations can’t just cease while any remedial work is carried out so any cyber security measures will usually have to be implemented while operations are still running. And issues such as the skills gap among employees, budget constraints, resistance to change and uncertainty about where to start, are further complicating the process, making it difficult for manufacturers to take the first steps toward a robust cyber security strategy.

However, it is something that must be done and there are some steps to be taken to help.

The risk assessment of what you want to do, what impact it will have and if it is the right thing to do. Is this the place where you should start? These are all questions which need to be answered before implementation. It also allows the right systems to be prioritised as well as avoiding wasted resources with over-engineering and under-securing.

Businesses must find out what’s already in place with regards to cyber security. This evaluation prevents businesses from ‘reinventing the wheel’ and allows them to leverage and strengthen what they already have rather than starting from scratch. Some systems may only need updating or additional monitoring which could drastically increase protection without unnecessary spending or a full overhaul.

Manufacturers must test their systems and not wait for an attack before seeing how they work. Cyber security companies can mimic an attack and then work with manufacturers and their defensive teams to look at how the business and its systems respond when bad things happen. This ensures that you have worked through each step of the process, so if something happens in the real world, you are practiced and prepared. You will know any areas you need to improve on and have a timeline of recovery in case of future attacks.

Because the relationships we build with our customers are at the heart of everything we do.

We don’t just sell policies. We build partnerships.

We don’t just cover risks. We can help you avoid them.

We don’t just show up when something goes wrong. We’re with you every step of the way.

DA: “Although the UK manufacturing sector has previously been recognised as a global powerhouse, many say the pace has slowed due to underinvestment. What do manufacturers tell you is deterring them from investing in automation and robotics in 2025?”

MW: “There is a longstanding perception that Automation and Robotics (A&R) is expensive, difficult and requires highly specialised skills to deliver within a business. Small businesses are understandably cautious when investing in new technology, especially when

additional cost is involved. The other consideration is how it will directly impact productivity and output, which is often difficult to measure before implementing.

“Uncertainty around things like tariffs and – until recently – the lack of a clear, long-term Industrial Strategy haven’t helped either.”

TB: “When we look to other developed economies around the world, we see a more long-term mentality where it’s not unusual for manufacturers to have investment cycles with return assumptions that can be up to ten years long. In the UK, there is a much shorter return expectation, which can prevent firms from deciding to invest in A&R. There can also be a perception of A&R as being ‘nice to have’ rather than being critical for long-term competitiveness.”

DA: “What would you say to manufacturers to help overcome these concerns?”

MW: “Manufacturers would benefit from being more competitive and productive, both of which can be achieved through A&R adoption. These systems do not have to be as expensive as is often perceived,

and training is widely available to help upskill employees.

“It also looks like we are getting some longer-term stability through the new Industrial Strategy and the agreement of international trade deals.”

TB: “A&R is key to long-term competitiveness. The work being done by the likes of MTC is helping bring the technology to the fore and make it more accessible, but it’s also down to Lloyds and other lenders to normalise funding for A&R.

“There’s an argument that historically our sector perhaps hasn’t understood A&R as well as it should, and now we have to make sure manufacturers know that we support these kinds of investments, and not just for larger businesses, but for small and medium-sized businesses as well.”

DA: “What kinds of A&R solutions are available for UK manufacturers and what applications do they have? And what about financing?”

MW: “There’s a full range of robot solutions that are available, many of which have a proven track record of

delivering improved productivity. Solutions like machine tending, welding and palletising would be good starting points for many manufacturers who have not implemented a robot solution before.”

TB: “From a financing perspective, traditional banks like Lloyds are happy to fund investment in A&R with relatively standard Asset Financing products like Hire Purchase. But, while there are some very straightforward A&R applications, like autonomous forklift trucks, procurement can also sometimes be complex.

“It might involve a systems integrator going to a panel of suppliers and piecing together a bespoke solution, and a lot of A&R manufacturers are overseas, which can present some challenges in funding that upfront cost. There are options to secure initial loans that then translate into a traditional Hire Purchase product once the solution is put together and is functioning."

DA: “What is the first step for manufacturers who are exploring the automation opportunity?”

MW: “The first step is getting the necessary help and support to select the most appropriate application.”

TB: “After identifying this, the next step is to approach a lender like Lloyds to provide a financing solution that suits your plans, which might be a fairly generic product or a more tailored package. We are also working with the A&R supply chain to develop a proposition to make their products more attractive and accessible. That means partnering with the manufacturers, distributors and systems integrators to provide funding alongside their technologies.

“It’s another way we can help manufacturers connect the dots and find the financing solution for them, so watch this space!”

DA: “How can manufacturers minimise the risk that comes with investing in automation?”

MW: “Independent support is available from organisations including MTC, the High Value Manufacturing Catapult and others to help guide you through the procurement journey. That can include

developing the business case, writing a requirements specification and selecting the most appropriate supplier.”

TB: “Where manufacturers face a cash flow challenge, we can help, whether that's with an Invoice Financing solution, a trade finance facility or Asset Finance that enables them to take on more business and grow more quickly. We can help them understand exactly what that means in terms of monthly payments to support their budgeting and planning, and make it easier for businesses to say yes to investing.”

DA: “UK manufacturers already have a skills shortage. Could automation actually attract more people to work in manufacturing?”

MW: “Absolutely. A&R helps address skills shortages in two ways. Firstly, for example in welding, robots can undertake the mundane, repetitive tasks, being tended by unskilled personnel. The skilled welders can then apply themselves to more complex tasks, creating more interesting, satisfying jobs where their skills can add real value. Secondly, it’s creating interesting, stimulating jobs that are far more appealing to tech-savvy young people.”

TB: “I agree that A&R is a route to creating higher skilled, higher paid jobs that that can encourage more diversity in manufacturing and ultimately help build businesses that are more competitive in the long-term.”

DA: “What is the ultimate prize at the end of the automation journey?”

MW: “Manufacturers that can effectively integrate A&R into their processes will find that they can achieve improved productivity and competitiveness leading to growth and greater profits, with happier colleagues working in more highly skilled and better paid jobs.”

TB: “We're seeing an opportunity to boost UK competitiveness by raising levels of investment in this kind of cutting-edge technology. Investing in A&R is a huge opportunity to bolster the long-term resilience and strength of UK manufacturers and the UK economy.” l

“

“ Being more competitive and productive can be achieved through A&R adoption

Prof Mike Wilson We're

Tim Biddle

September once again saw the team from The Manufacturer hit the highways of the UK as The Manufacturer MX (TMMX) Awards programme reached its moderating stage. Here we’ve gathered insights from finalists and judges alike on the benefits of the programme and why it is crucial to UK manufacturing

Aunique element to TMMX Awards programme is the fact that the second and last phase of the judging process sees our finalists open their doors to our judging teams, where they are assessed on the evidence previously submitted during phase one.

Not only does this process give the judges unprecedented access to peak under the hood of the finalists and to have the opportunity to probe and ask questions, it also provides the finalists themselves with fantastic feedback which can help shape their strategy and benchmarking in the future.

Taking place over three to four days, the

site visits often involve the moderators and judges clocking up hundreds of miles as they scour the length and breadth of the country in search of that year’s most innovative businesses. The Manufacturer would like to thank the judges for giving up their time and expertise to assist in the process, the finalists themselves for supporting the programme and our sponsors, without whom the awards would not be possible.

So, from the nation’s smartest factories to our most sustainable manufacturers; from the ground-breaking product innovators to the most inspiring leaders, the awards truly encapsulate the best the UK sector has to offer. Here’s what the judges and finalists had to say.

ABOVE: BMW (UK) Manufacturing, Swindon Pressings - finalist, Leadership & Strategy

There are very few platforms that truly celebrate the intricacies of production: the details, discipline and innovation that happen on the factory floor. TMMX Awards does exactly that, shining a spotlight on where ideas are transformed into real products.

The awards process has been rigorous yet rewarding. What stood out most for us was the in-person visit, as it gave us the chance to demonstrate not just our production flow on paper, but in action; for the judges to see our team, technology and culture first-hand. That opportunity to open our doors and let the judges experience Specscart’s way of working was invaluable, and it made the whole process far more meaningful for our team.

If you run a factory with passion, and your team continues to deliver efficiency and innovation despite the challenges of the economic climate, then this is the platform for you. TMMX Awards gives you the chance to showcase how you bring technology and people together to build exceptional products while keeping costs fair for the end consumer. It’s not just about recognition from the outside world, it’s about celebrating your team’s achievements. Entering these awards is a powerful way to acknowledge the resilience, creativity and problem-solving that go into overcoming production challenges every single day. For us, it has been as much about giving our team a morale boost as it has been about benchmarking ourselves against the best in the industry.

Sid

Sethi, Founder, Specscart –finalist: Smart Factory

As an SME, we’ve created a truly unique culture of innovation. By investing in our people and fostering an environment where every idea is valued, we elevate everyday challenges into highperformance products and solutions, trusted in healthcare, defence and major data centres across the UK and beyond.

Our long-term contracts with leading global clients validate that our approach to people, culture and innovation is not just successful, it’s transformative.

Lou Ellis-Frankland, CEO Mansfield Pollard – finalist: Product Innovation & Design

We’ve achieved in two and a half years what typically takes far longer: designing, launching and scaling a product across seven countries, fully compliant with challenging standards. With a small, empowered team, we built the end-toend infrastructure, from manufacturing to installation, while maintaining transparency, quality and commercial viability.

Alexander Wilson, Product Director, Uplifts – finalist: Product Innovation & Design

Our purpose for entering the Operational Excellence category was twofold. We wanted to create a different method in which to recognise and celebrate the

team’s OpEx progress, and secondly, to get some valuable benchmarking and constructive, critical feedback from the experienced judges to inform the next steps on our OpEx journey.

“

The opportunity to open our doors and let the judges experience our way of working was invaluable, and it made the whole process far more meaningful for our team

Sid Sethi, Founder, Specscart

To sum up this process in one word? Valuable. We took care over our application to make sure we were speaking with data, and this was recognised by the judges. We also used the on-site visit to enable the team to practice presenting their progress to others. It’s been hard work, but well worth the effort.

There are areas in which I think our team are fantastic, but there are others in which we know we can still make huge improvements. That’s why entering the awards is such a valuable milestone on our journey and that is what we are celebrating with the team.

Jamie Dummer, Managing Director, ROSS Pneumatrol – finalist: Operational Excellence

The process so far has been smooth, engaging and I’ve really appreciated the judges’ time, comments and support. Entering the awards gives you the opportunity to speak to very skilled, professional people who are already successful in their careers. To be able to present to them and get their feedback gives you valuable insight around your own development; it's a great opportunity.

Jordon King, Head of Business Development, Delta Fire – finalist: Young Manufacturer of the Year

Having joined Tornado as CEO relatively recently, I found a business that is doing some fantastic things, but doesn't always shout about them. So, my idea of entering TMMX Awards was to prove to the team that we are doing some really great work, and that we belong at the table with these other fantastic businesses. And so far, the process of reviewing everything that we've been doing and sharing that with the team has been really motivational. So regardless if we win or not, it's already been a very positive experience for us.

Rebecca Galley, CEO, Tornado Wire –finalist: Product Innovation & Design

We entered TMMX Awards to benchmark ourselves against the best in UK manufacturing and validate our progress.

It’s also a rare opportunity to pause and reflect. Every day, we’re critically thinking, solving problems and chasing improvement. The submission and judging process allows us to step back and enjoy sharing our journey and the wins we’ve achieved together.

Our Hoshin Kanri planning and ‘We Deliver’ culture ensures everyone is aligned to strategic goals. This clarity enables agility and resilience. Our lean methodologies and digital tools like CoCo also drive improvements in quality, cost and productivity, and structured problem-solving empowers teams to act quickly and effectively.

The categories we’ve entered are explicitly linked: Leadership & Strategy defines the vision, Operational Excellence and Supply Chain Excellence bring it to life, and Smart Factory amplifies the results. Together, they form a cohesive story of transformation, resilience and ambition - one we’re proud to share.

Dave Reynolds, Factory Manager (FF1) & Head of Engineering Services, Siemens Congleton – finalist: Leadership & Strategy, Operational Excellence, Supply Chain Excellence, Smart Factory

Four days of factory visits and in-depth discussions provide a rare chance to get under the skin of innovation in UK manufacturing. It is both energising to see new ideas and approaches in action, and sobering to see the challenges that remain.

The TMMX Awards are a snapshot of where UK manufacturing is today. They reveal a sector that is full of ideas, experimenting with new ways of working, and seeking to stay competitive in a challenging global market. But they also remind us that innovation is not a slogan. It is a discipline and one that requires clarity, courage and above all, a relentless focus on the customer.

Gordon Macrae, Independent Consultant - judge: Product Innovation & Design

I wanted to judge the Operational Excellence category this year as it speaks to the core of what I do and I wanted to see how digital technologies are underpinning that.

At the companies we visited, the leadership and commitment was there for all to see. What was interesting is that the digital piece wasn’t being overdone; it had all been very well thought through and focused around what is being delivered to the customer.

The finalists also demonstrated how the overall strategy is being cascaded down to the shop floor, so there was a really strong thread all the way through the OpEx model. For me, that was the eyeopener, and what I really wanted to see.

Alison Beard-Gunter, Transformational Director, Thermo Fisher – judge: Operational Excellence

As always it was a challenging and intense process, but extremely rewarding, as in return it was fascinating to meet with representatives from the category finalists and see them demonstrate with passion their services, products and processes.

TMMX Awards are an ideal opportunity to promote and support UK manufacturing, showcase products, processes and services, generate new leads, develop employee engagement, gain business recognition and it provides a perfect springboard for networking with likeminded people.

Mike Higgins, retired Change Management Co-ordinator, ZF Chassis Modules - judge: Product Innovation & Design

I'm proud to see such world-class manufacturing capabilities thriving here in the UK, reinforcing the nation's reputation as a leader in industrial innovation and excellence.

Having judged this category in previous years, I get to see the incredible speed that businesses are developing smart digital solutions; more importantly, solutions that really are supporting and driving business benefits.

It was also inspiring to meet the teams implementing the solutions at the coal face - the energetic and talented apprentices through to the insightful business leaders setting the strategy and vision. The commitment to continuous improvement, passion, innovation and workforce empowerment stood out as exemplary.

Adrian Chell, Plant Director, ZF Groupjudge: Smart Factory

TMMX Awards encourage people to think about what they've achieved in their businesses and how they can present it to the outside world. It also shows them how they can use that for their own development and indeed, to inspire and motivate their own people.

As in previous years, this year's finalists have all shown how much initiative you need to develop export business. It does need a lot of drive, but it can be done; and done very successfully. It's a quality that the UK has had for years, if not centuries.

Peter Flinn, MBE, Past President, Institution of Mechanical Engineersjudge: International Trade

It's important that manufacturers have that commitment and understanding that ED&I is not something you do on the side, but something that should be integrated into the wider picture of what you're doing as a business. Without that you limit not only your pool of employees, but the scope of the work that you're doing.

We need to celebrate and recognise excellence where it happens. We can all get very bogged down in our day-to-day, but TMMX Awards is a celebration of how great and wonderful manufacturing and engineering is, and how it's impacting a lot of people's lives and society. I think that's something that needs to be showcased and rewarded.

Joyce Achampong, Associate Director, Impact, Institution of Mechanical Engineers – judge: Equity, Diversity and Inclusion

This is my second year in a row serving as a judge for the Smart Factory category of TMMX Awards. It's been such a privilege to witness the achievements of UK manufacturers, to shake hands with apprentices on the factory floor and to absorb the energy, enthusiasm and professionalism of those driving digital transformation in their businesses. My personal thanks and congratulations go out to each of the factories that we visited, all of them very special in their own unique ways.

However, while the progress made since last year could not be disputed, it's hard to ignore the undercurrent of concern about the risks and vulnerabilities of digital connectivity to outside attacks. No doubt this will be a hot topic over the next 12 months and it will be fascinating to see how this influences the entries of the 2026 Smart Factory category.

Kevin Bull, Product Strategy Director at Columbus - judge: Smart Factory

It's been such a privilege to absorb the energy, enthusiasm and professionalism of those driving digital transformation in their businesses

Kevin Bull,

Director, Columbus “

Product Strategy

Research has revealed that 68% of UK manufacturers are hit by downtime losses reaching up to £982m per week. As Parker Burke, Group President, Fluke Corporation explains, connected reliability has emerged as a strategic imperative to enhance resilience, customer trust and growth

When business leaders reflect on the risks most likely to derail performance, it is tempting to think of downtime as something sharp and contained. But for manufacturers, downtime has always been the epitome of risk. A silent tax on productivity that erodes margins, exposes vulnerabilities across operations and undermines customer confidence.

When we think of risks to operations, many point to those that are likely to capture headlines: from cyber attacks to regulatory changes, these are interruptions that arrive suddenly.

Yet, downtime is rarely the result of a single cause. Fluke’s latest research across the UK, US and Germany shows it emerges from a multitude of challenges. Each cause of an incident may differ in origin, but their impact converges in the same place: production lines that stand still, orders that go unfulfilled and value that evaporates by the hour.

Downtime without boundaries

The scale of the challenge is significant. Fifteen per cent of manufacturers report downtime events lasting up to 72 hours, long enough to choke supply chains and undermine customer delivery. Nearly one in five experience multiple incidents each day, highlighting vulnerabilities that conventional maintenance approaches cannot contain. At the higher end, manufacturers across the countries surveyed absorb an estimated

“ In today’s climate, resilience has become the defining currency of competitiveness

Parker Burke, Group President, Fluke Corporation

$852m in downtime costs every week.

Interestingly, the shock of downtime doesn’t strike evenly. Its frequency, duration and intensity vary by region and industry, shaping distinct risk profiles. For some, the threat lies in long, infrequent stoppages; for others, it is the drumbeat of repeated, short disruptions. Yet in all cases, downtime compounds quickly; turning operational weakness into a competitive disadvantage and negatively impacting the bottom line.

The data is clear: reliability is an underestimated vulnerability.

The hidden cost of reliability failures in the UK

Reliability failures differ from the headlinegrabbing crises that dominate board agendas. They erode productivity in quieter ways, straining assets incrementally and often escaping executive attention. But the numbers don’t lie, when you add up the incremental costs, they have enterprisewide consequences.

The reality of downtime in the UK illustrates this vividly. Over the past 12 months, 68% of UK manufacturers have endured unplanned downtime. For many, this is not an occasional shock but a regular occurrence. Some report more than ten incidents every single week. Nearly half of these outages last up to 12 hours, while close to one in five (17%), extend up to 72 hours. The financial toll is more severe than the global average, with unplanned downtime costing the UK sector up to £982m every week.

Downtime as a compounding liability

The immediate effects of downtime are visible in lost revenue, contractual penalties and delivery delays, but it is the secondary consequences that cause the most lasting damage. Productivity ebbs away, service costs rise and employee frustration builds, driving attrition in a labour market that is already stretched thin.

For customers, repeated outages translate into declining confidence. For investors, they raise questions about leadership’s ability to execute consistently. For the organisation itself, downtime gradually undermines the very priorities that surveyed UK manufacturers say matter most: competitive differentiation (21%) and enhanced customer experience (18%). These ambitions cannot be met if unplanned outages remain unmanaged.

Resilience is no longer an optional attribute that companies can pursue when convenient. It has become the central test of whether an organisation can sustain growth, preserve trust and deliver consistent value under volatile conditions.

Fragmented approaches and missed opportunities

This challenge is widely acknowledged, and it is reflected in the scale of investment that manufacturing leaders are making. IDC forecasts that global digital transformation spending will approach $4tn by 2027, with manufacturing responsible for a significant share of that growth. Yet while the commitment to invest is clear, the strategies being pursued are often fragmented, reflecting experimentation rather than system-level transformation.

Fluke’s research highlights a growing focus on technologies such as condition monitoring (13%), predictive maintenance (12%) and digital twins (12%). Each offers meaningful value by improving visibility, enabling better asset management and creating pathways for proactive risk management. However, when these tools are deployed in isolation of a clear maintenance strategy, they risk generating more data without generating more resilience. Information remains siloed, decision-making slows, and vulnerabilities remain embedded. Often vendors mistake incremental technology adoption for structural change; more technology isn’t the answer.

Over the past 12 months, 68% of UK manufacturers have endured unplanned downtime

reliability as a foundation for resilience

The more powerful alternative is what we call connected reliability; the integration of hardware, software and services into a single, data-driven framework that allows predictive intelligence and real-time decision-making. With this approach, organisations move beyond reactive fixes towards foresight, coordination and proactive value creation.

At scale, connected reliability does not merely keep operations running. It extends the lifespan of critical assets, reduces wasteful capital expenditure, improves ROI and embeds accountability across the enterprise. It also delivers measurable progress on ESG commitments by optimising energy usage and resource allocation, while giving leadership teams the clarity and confidence required to steer through turbulence.

Reliability, once viewed as an operational afterthought, becomes measurable, reportable and directly tied to business performance. It shifts from being a defensive safeguard to an enabler of growth.

Turning disruption into advantage

In today’s climate, resilience has become the defining currency of competitiveness. Connected reliability presents as the biggest opportunity available to achieve it.

The leaders who will define the future of manufacturing will not be those who manage to avoid downtime altogether, because that is impossible. They will be those who anticipate shocks, absorb them and adapt more quickly and effectively than their peers.

Done well, connected reliability becomes a source of advantage, enabling manufacturers to deliver more consistent performance, strengthen trust with stakeholders and create a foundation for long-term growth. l

In today’s fast-evolving B2B landscape, digital transformation is no longer a competitive advantage but a necessity. Technology continues to reshape how businesses operate, as well as the buying expectations of customers. They’re looking for a quick, seamless and user friendly experience

The path from traditional, offline processes to fully integrated digital operations is often daunting. Manufacturers are sometimes guilty of running to the wrong outcome, instead of walking to the right one. Lance Owide, Vice President and General Manager of B2B at BigCommerce, gives his thoughts on achieving true digital maturity.

Why is now the time to prioritise digital maturity?

LO: There are so many benefits that digital maturity brings, which I will explain. But mostly, the time to make this a priority is now, because it’s what the buyer expects.

The generation that was sending faxes and emails are being replaced by younger people. They want to have an online process where they can self-serve. Your buyer experience can be your

differentiator. I was speaking with a large manufacturer in the construction sector recently. They were saying that their customers routinely cite the buyer experience as a reason for returning. They’re now able to purchase online from this business, find products easily and have personalised experiences that build automatically. They're also embedding AI into that experience. This sets them apart from their competitors.

That's why the time to prioritise digital maturity is now. If you don't, you will start falling behind.

What does digital maturity mean in practical terms for a manufacturing business?

Digital maturity is a very broad scale. It starts with everything that's completely offline and goes through to everything being connected.

Data is at the core of everything. This goes beyond just having product data; there’s pricing data, customer data, historic trend data and everything in between. And digital maturity starts by having the right data.

Then, it’s about systems. Are those systems able to meet the needs of your business as you digitally transform? We know so many manufacturers out there on custom ERP; they built their own because nothing was available that met their needs or they wanted a sector specific ERP. But it doesn't connect into any APIs or any other system.

And then finally, it's about people. You need to have people in the business that are thinking digital first, and can help drive digital maturity. In many cases you need to re-architect the processes that the business relies on, and you need the right people and expertise to enable that.

What are the main stages on the path to digital maturity, and where do manufacturers get stuck?

The truth is that many people get stuck at the very first, and most important part, which is alignment to business objectives.

Digitalisation needs to drive something - it might be to grow revenue, increase profit margin or to expand into new geographical regions. You should anchor in a specific business objective and everything should cascade from that. I see so many businesses that don't do this and they don’t achieve alignment.

Once a business is aligned, it’s important to take things in stages - crawl, walk, run. You don’t need to get to the end state immediately. If you take this graduated approach then it becomes more manageable, and the business can digest that change more easily.

Start with the data. If that means you don't have product data, or you don't have a connected ERP, then start there; fix those processes first.

When it comes to ecommerce, I would suggest starting by launching an informational site. If you don't have a website that has your products on today, launch a site that does. It doesn't need to be transactional, but just create that online catalogue instead of only being offline.

Phase two might not even be transactions. It might just be that you can now put those products into a quote and send a request for one.

Phase three might then be the point where you can move to being fully transactional. You can take those products into a cart and actually transact with them. All the product information is built into the site, all of the technology specs are installed; such as AI-powered chat bots that pop up and help to answer questions about the products.

You can get yourself to that top level of digital maturity, but for me it's about being aligned to the business and taking gradual steps that will enable you to get there.

You should anchor digital transformation to a specific business objective and everything should cascade from there

Lance Owide, General Manager of B2B, BigCommerce

Ready to take the first step? Don’t wait until your competitors are running ahead. Start small, align your digital goals to your business objectives, and build momentum. Find out how you can begin your crawl-walk-run journey to digital maturity: www.bigcommerce.co.uk/dm/ b2b-edition-demo

Why do you think the digital gap in B2B, and particularly in manufacturing, has persisted for so long?

A lot of manufacturers, particularly in the UK, have been around for years. A lot of them are very well respected and successful businesses.

As the saying goes, ‘if it ain't broke, don't fix it.’ I think that has often been the mindset of these businesses. They don’t want to risk giving a team something they don't like, and they’re worried that it might ultimately slow down growth.

Also, it can just feel like an incredibly high hurdle. To move from outdated systems to a fully digitised business can feel like a monumental challenge. As mentioned, you need people who have done it before and have the experience.

What advice would you give to a manufacturing leader about accelerating their digital maturity?

As mentioned, make sure you're always anchored in your business objectives.

Secondly, bite the apple one little bit at a time; you don't have to eat the whole thing all at once. Crawl, walk, run – plan it out that way.

Then finally, success is about getting internal alignment. Prove to the business the value that you're going to drive. Do that by putting your customers at the core, understand their problems and how you're going to drive success and experience for them. But make sure you get the alignment internally. l

A recent visit to China revealed just how far the UK’s once-thriving chemicals sector lags, held back by rising costs, skills shortages and disjointed support. Could increasing our collective appetite for risk secure survival and unlock new growth? Jonny Williamson reports

China is moving discoveries from the lab and out to market at a furious pace and scale, underlining its shift from global imitator to leading innovator.

Professor Raffaella Ocone is no stranger to China, yet even she was taken aback by the ambition on display during her latest visit.

Invited to speak at the 12th World Congress of Chemical Engineering in Beijing, the President of the Institution of Chemical Engineers (IChemE) admits the experience left her feeling overwhelmed.

“The level of innovation in China is astonishing,” she said. “Its pathway for advancing innovation through technology readiness levels is well developed, understood and agile, bringing discoveries to market faster and more effectively than almost anywhere else.”

That speed and clarity of purpose is what the UK is struggling to match. But without policy alignment, affordable energy and access to talent, the UK will always have one hand tied behind its back.

The engine for economic growth Innovation drives growth, but chemistry is what keeps the engine running. Almost every aspect of daily life depends on chemical innovation, and it’s chemical engineers who turn these discoveries into safe, scalable and commercial processes. Whether producing strong, lightweight composites, delivering cleaner energy or cutting waste in food production and pharmaceuticals, their work is the glue that holds manufacturing together.

That blend of science and engineering has long been the UK’s strength, tied to its pioneering role in the Industrial

UK CHEMICALS AT A GLANCE

Revolution and its establishment of the world’s first chemical engineering course. While the UK continues to perform strongly in research and education, it struggles to commercialise that research, something many others – China included – do far better.

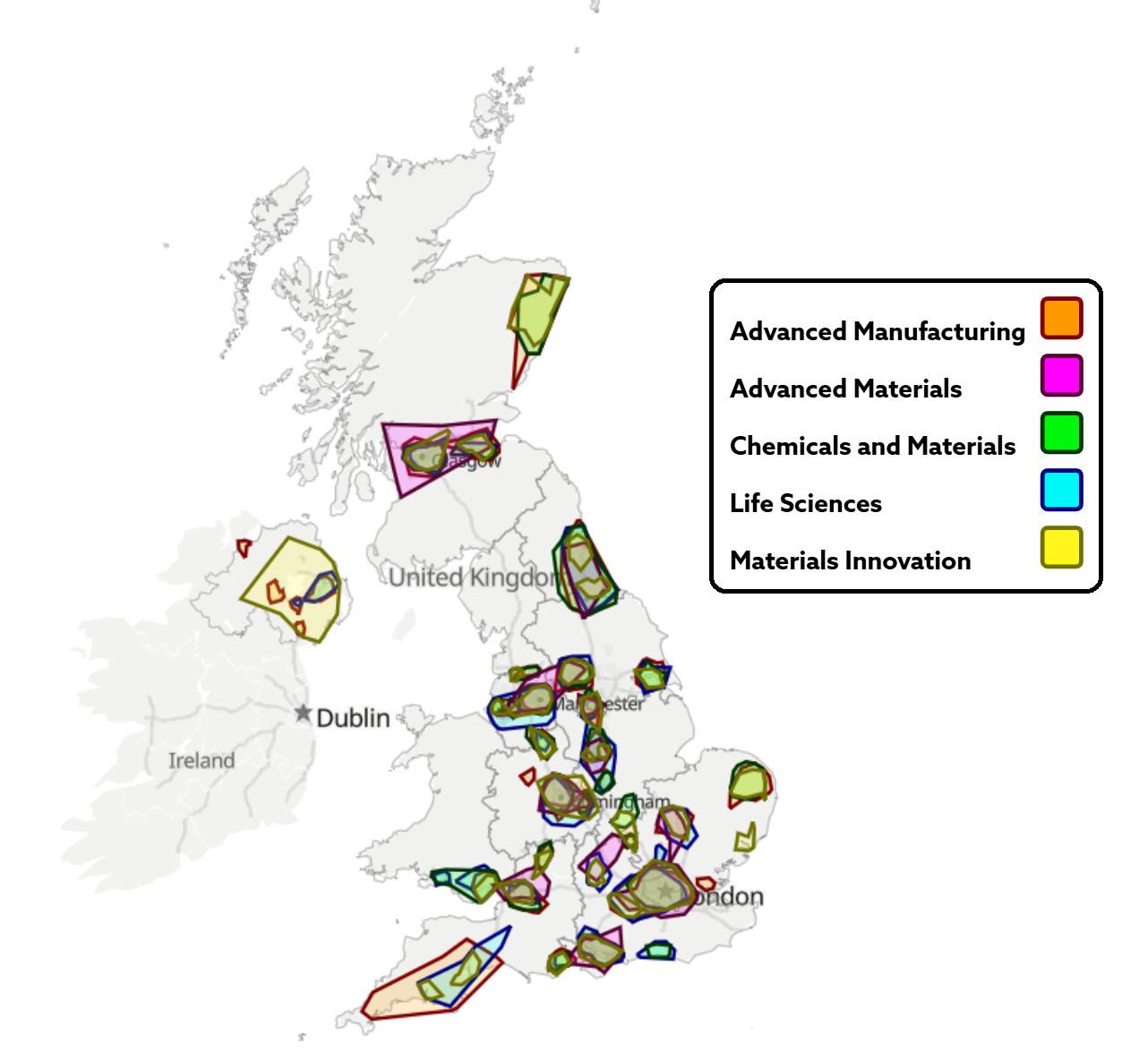

The pages of The Manufacturer frequently discuss the UK’s so-called ‘valley of death’, where new ideas fail to mature. For Raffaella, that gap lies between technology readiness level (TRL) 3 and 6 where a project moves from proof of concept through basic lab validation to real-world demonstration. Bridging it is crucial if the UK is to turn research into competitive advantage on the global stage. Doing so, Raffaella says, rests on three things: industrial clusters, deeper coordination and greater diversity.

*Figures courtesy of the Chemical Industries Association

£22bn 140k 12% 40% 96%

Directly contributes nearly £22bn GVA to the economy Employs nearly 140,000 people, with wages 32% higher than the average

Clusters for transition and growth

A clear priority is making sure the UK’s network of industrial clusters – from the Cornwall Space Cluster to the Scottish Decarbonisation Cluster – functions as a genuine driver of innovation and growth. Co-located groups of industries sharing infrastructure, supply chains and skills are central to the UK meeting its largescale goals, while securing a foothold in emerging markets.

Take net zero. Multiple clusters have been established to anchor the shift from petrochemicals to cleaner alternatives.

The Acorn carbon capture and storage project, for example, is using legacy oil and gas infrastructure to send captured industrial CO2 emissions to permanent geological storage under the North Sea. The hope is that Acorn can eventually use non-pipeline transportation to move captured CO2, helping to support the decarbonisation of industry across the UK and even internationally.

Part of the Scottish Decarbonisation Cluster, Acorn is one among several industrial, power, hydrogen, bioenergy and waste-to-energy businesses with the shared aim of capturing ten million tonnes of CO2 annually by 2030 – and in doing so, creating thousands of long-term, highly skilled jobs and countless supplier opportunities.

But Raffaella warns that the opportunity

comes with a lesson. The collapse of coal mining showed how quickly entire regions can be left behind when industries vanish overnight. Clusters, if well-designed and supported, can prevent that mistake, providing a bridge from oil and gas to cleaner growth – reskilling workers and attracting new investment in the communities most at risk of decline.

Clusters and industries can only thrive if underpinned by the right skills. Reskilling and upskilling workers from oil and gas, for example, is key to delivering the energy transition. And it is a transition, Raffaella notes, not a substitution. The expertise honed in petrochemicals – from process safety to managing large, complex operations – is exactly what’s needed in carbon capture, hydrogen, offshore wind and battery storage.

But Raffaella argues that the future of chemical engineering depends not only on reskilling but also on widening the profession’s intake beyond its traditional boundaries. She points out that engineering remains one of the least gender-diverse professions, with women making up less than 16% of engineers overall, and 22% in chemical engineering. Without change, the sector risks shutting out talent and narrowing the

ABOVE: From clean energy to defence, chemical engineering underpins all eight of the UK’s Industrial Strategy growth sectors

Diverse teams create diverse ideas, and that’s what drives innovation... no doubt, the future of chemical engineering is bright

Professor Raffaella Ocone, President of the Institution of Chemical Engineers (IChemE)

For the Industrial Strategy to succeed, we must be braver, louder and more willing to take risks together

Professor Raffaella Ocone, President of the Institution of Chemical Engineers (IChemE)

perspectives needed to solve complex, global problems. “Diverse teams create diverse ideas, and that’s what drives innovation,” she stressed. That means tackling barriers head-on through outreach into schools and communities, mentoring networks and targeted training to help attract and retain fresh talent.

LEFT: 2025 snapshot showing just some of the Innovation Clusters across the UK. Image: The Department for Science, Innovation & Technology

BELOW: The Acorn project shows how legacy oil and gas infrastructure can be repurposed to send and store CO2 beneath the North Sea. Image: The Acorn Project

IChemE’s schools outreach programme, DiscoverChemEng – credited with driving a double-digit increase in the number of students studying chemical engineering –shows the impact of early engagement.

Yet, as Raffaella notes, not everyone can afford to go to university. If the sector is serious about broadening its base, it must create and promote non-traditional routes into chemical engineering, from apprenticeships and vocational pathways to stronger links with colleges and industry training programmes.

“Opening these doors will bring in talent from a wider range of socio-economic backgrounds and ensure the sector is drawing from the full breadth of skills the UK has to offer.”

Coordination as a catalyst

The latest world innovation league table shows the UK has slipped to sixth place, down from fifth last year and fourth the year before. At the same time, China has entered the top ten for the first time. If the UK is to reverse this trend and capitalise on its world-class R&D base, it must coordinate its industrial, academic and policy efforts.

Fragmentation has long been a weakness. Industrialists often undervalue the role of academics, government support is uneven and each part of the innovation chain tends to pull in different directions. That lack of alignment is a likely contributor to the ‘valley of death’ between TRL 3 and 6.

Raffaella is hopeful the recently published Industrial Strategy offers a chance to break this pattern. The tenyear roadmap is ambitious in scope and rightly places skills at the heart of the UK’s future competitiveness. Yet while the direction is set, details on delivery mechanisms are still missing.

“Chemical and process engineering may not be explicitly named, but it is the enabler that underpins all eight sectors the government has designated ‘high potential’,” Raffaella said. “Chemical engineering is also central to the foundational industries, ensuring they and all industries continue to operate while reducing emissions and working towards a more sustainable world.”

Signs of progress are emerging. IChemE is already working with the Chemical Industries Association (CIA), the Royal Society of Chemistry (RSC) and

Professor Raffaella Ocone is a Professor of Chemical Engineering at Heriot-Watt University, where she has been since 1999. Her more than 30 year career spans Italy, the US, France, Germany and the UK, giving her a deep understanding of the value of international exchange in fostering inclusive progress.

Her expertise lies in complex reactive systems and their applications across the energy sector. She has been a leading voice in the teaching of engineering ethics and promoting responsible technologies for the energy transition. In recognition of her contributions to engineering, Raffaella was appointed Officer of the British Empire (OBE) in The Queen’s 2019 New Year Honours list. She has also been named as one of the top 100 Most Influential Women in Engineering.

“My own story is a testament to the importance of visibility and opportunity,” Raffaella reflected. “From being a student in my native Italy to becoming the first female professor of chemical engineering in Scotland, you could argue I am living proof of what is possible when barriers are broken down. But my story, sadly, also highlights how rare an example I am.”

As President of the Institution of Chemical Engineers (IChemE), Raffaella champions diversity, inclusion and ethical practice, advocating for wider access to the profession and highlighting the pivotal role chemical engineers play in tackling global challenges.

the Society of Chemical Industry (SCI) to press the government to explicitly recognise the vital role of chemistry and chemical engineering in the UK economy, and to secure continued investment in technician, reskilling and graduate programmes.

“We have an incredible opportunity to work in a very synergetic way towards the delivery of this strategy. But we cannot do it in isolation,” Raffaella added. “If we don’t step up, speak up and make our role clear, we risk losing it.”

From risk to reward

What ties Raffaella’s threads together - clusters, coordination, diversity – is appetite for risk. China’s speed isn’t just a matter of scale, she argues, but a systemwide acceptance that some failure is part of progress. In the UK, by contrast, fear of failure too often curtails investments, prolongs pilot projects and leaves promising advances stranded in labs.

Changing that mindset means two things. First, we must take smarter, shared risks so no single party carries the burden alone. Second, we must be far more vocal about the wins that do emerge.

The UK is building world-class expertise in areas like hydrogen, carbon capture, biotech and life sciences. Success stories such as the rapid development and scale-up of the COVID-19 vaccine shows what’s possible when chemical engineers, manufacturers, policymakers and scientists act in concert.

But too often, those stories stay hidden. “We live in an era of communication and information,” Raffaella explained. “We need to share what works and demonstrate how chemical engineering impacts people’s everyday lives. Without it, we would never have had a vaccine, never mind producing enough to vaccinate the whole population. If we want the Industrial Strategy to succeed, we must be braver, louder and more willing to take risks together.” l

Now in its 17th year, Manufacturing Leaders’ Summit has established itself as one of the most important gatherings for senior professionals across UK manufacturing. Taking place on 11-12 November in Liverpool as part of The Manufacturer Live series, the summit once again promises to bring together over 250 influential leaders from across the sector, spanning defence, aerospace, automotive, food and drink, pharmaceuticals, electronics and more

The event offers far more than keynote speeches and panel discussions. At its heart is a programme of interactive roundtables, designed to spark meaningful dialogue on the real challenges manufacturers face day-to-day. Delegates can expect not only thought-provoking insights from industry trailblazers, but also the chance to test ideas, exchange strategies and benchmark progress with peers facing similar pressures.

The summit is built around the principle that the most valuable insights come from open, honest conversations among practitioners. Across four focused 60-minute sessions spread over two days, attendees select the topics most relevant to their strategic priorities. Each session gathers small groups of leaders around a table to explore issues in depth, whether it’s workforce transformation, digital adoption or building resilient supply chains.

This format creates a rare space for candid discussion, moving beyond surface-level commentary into practical lessons learned. For delegates, it means leaving with ideas and approaches that can be applied directly back in their businesses.

As ever, the roundtable discussions will remain at the core of the event, covering themes such as operational excellence, digital transformation, AI and data strategy, supply chain resilience, sustainability, people and skills and cyber security. However, keynote presentations and expert panels will also zoom out to tackle the wider strategic landscape:

Turning disruption into opportunity

The UK manufacturing landscape is evolving at pace. Digital technologies and physical processes are becoming ever more tightly woven, creating both complexity and opportunity. The summit is designed for leaders who want to translate disruption into advantage and help them understand what’s next and how to get there.

Key themes for 2025

The agenda for this year’s summit is anchored in the sector’s most pressing priorities. Themes include:

• Excellence in Operational Strategy & Execution

• Developing Future-Ready Workforces: People, Skills & Leadership

• Smart & Scalable Digital Transformation

• Building Agile, Resilient and Transparent Supply Chains

• Harnessing AI & Advanced Analytics for Competitive Advantage

• Sustainable Manufacturing & the Road to Net Zero

• Cyber Resilience in a Connected Industrial World

The challenges on every leader’s agenda

Delegates will explore the full breadth of today’s manufacturing challenges such as:

• Economic and geopolitical shifts — from inflation and resource volatility to global trade tensions.

• Operational priorities — including energy management, asset optimisation and regulatory pressure.

• Organisational challenges — such as workforce retention, leadership in uncertain times and the demand for customised, faster production cycles.

• Embedding emerging technologies like AI, IoT and automation while managing legacy constraints.

• Responding to supply chain volatility amid geopolitical shifts and trade disruptions.

• Turning raw data into actionable insight while ensuring system integration.

• Protecting increasingly connected operations against cyber threats.

• Tackling workforce shortages through reskilling, automation augmentation and talent attraction.

• Balancing sustainability and net zero commitments with commercial performance.

• Navigating inflationary pressures, energy costs and resource efficiency.

• Meeting evolving customer expectations for speed, customisation and sustainability.

• Adapting to regulatory complexity and shifting international standards.

What you’ll gain in 2025

The value of the summit lies in actionable outcomes. Delegates will leave with:

• Tools to drive operational agility and continuous improvement.

• Insights to develop and retain future-ready workforces.

• Strategies for scaling innovation while managing cultural and technical barriers.

• Guidance on designing a future-proof digital strategy.

• Practical approaches to creating a datadriven culture across teams.

• A clearer understanding of which emerging technologies deliver real business value.

• New perspectives on building sustainable, resilient supply chains.

Rob Armstrong Vice President Manufacturing Engineering, Leonardo

Sofia Karlen Smart Factory Product Management Lead, Mars

Nigel Paine Vice President of Production, Carlsberg Britvic

Nicola Budge Chief Operating Officer, Willerby

Brian Stone Operations Director Halewood, Jaguar Land Rover

Ioana Hera Head of Lean, Rolls-Royce Read a full interview with Ioana on page 34

Alan White Head of Manufacturing, Proper Snacks

Petra Velzeboer Mental Health Leader

Darren Smith Business Delivery Lead for Underwater Battlespace & Autonomy, BAE Systems